Golf Mk4

| Assembly overview |

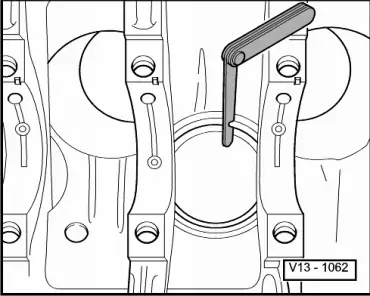

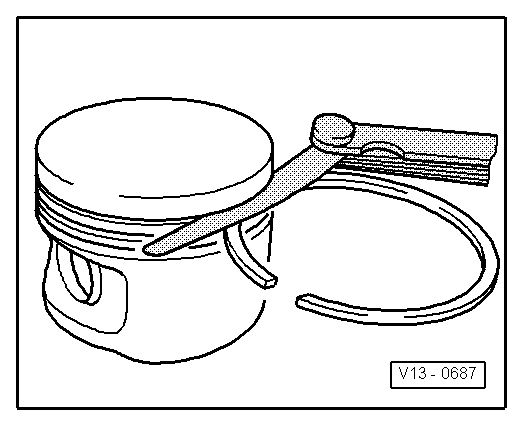

| 1 - | Piston rings |

| q | Offset gaps by 120°. |

| q | Use piston ring pliers to remove and install. |

| q | „TOP“ faces towards piston crown |

| q | Checking ring gap → Fig.. |

| q | Checking ring-to-groove clearance → Fig.. |

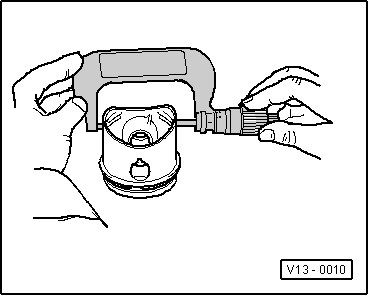

| 2 - | Piston |

| q | Checking → Fig. |

| q | Mark cylinder number and installation position relative to conrod. |

| q | Low point of piston crown faces to centre of cylinder block. |

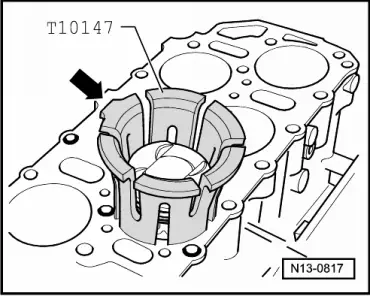

| q | Installing piston → Fig.. |

| 3 - | Circlip |

| 4 - | Conrod |

| q | Renew as set only. |

| q | Mark cylinder number -B-. |

| q | Installation position: marks -A- must be above one another. |

| 5 - | Bearing shell |

| q | Note installation position. |

| q | Do not interchange used bearing shells. |

| q | The lugs on bearing shells must fit tightly in the recesses. |

| q | Axial clearance: |

| q | New: 0.05…0.31 mm. |

| q | Wear limit: 0.40 mm |

| q | Check radial clearance with Plastigage: |

| q | New: 0.02…0.07 mm. |

| q | Wear limit: 0.10 mm |

| q | Do not rotate crankshaft when checking radial clearance. |

| 6 - | Conrod bearing cap |

| q | Mark cylinder number -B-. |

| q | Installation position: marks -A- must be above one another. |

| 7 - | 30 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Oil threads and contact surface. |

| q | To measure radial clearance, tighten to 30 Nm but not further. |

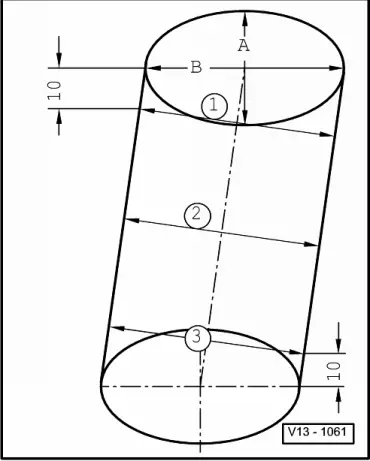

| 8 - | Cylinder block |

| q | Checking cylinder bores → Fig.. |

| q | Removing and installing crankshaft → Chapter. |

| q | Piston and cylinder dimensions → Chapter. |

| 9 - | Piston pin |

| q | If difficult to remove, heat piston to 60 °C. |

| q | Remove and install using drift -VW 222 A-. |

| Piston ring | Ring gap | ||

| New | Wear limit | ||

| Rectangular-section ring | mm | 0.20...0.40 | 1.0 |

| Tapered stepped ring | mm | 0.20...0.40 | 1.0 |

| Oil scraper ring | mm | 0.25...0.50 | 1.0 |

|

|

| Piston ring | Clearance | ||

| New | Wear limit | ||

| Rectangular-section ring | mm | 0.04...0.09 | 0.15 |

| Tapered stepped ring | mm | 0.03...0.06 | 0.15 |

| Oil scraper ring | mm | 0.02...0.06 | 0.15 |

|

|

Note

Note

|

|

Note

Note

|

|