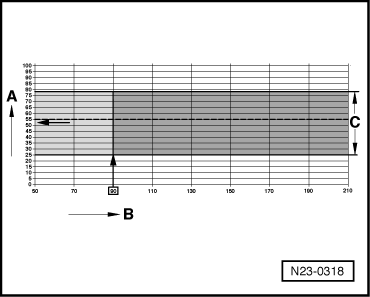

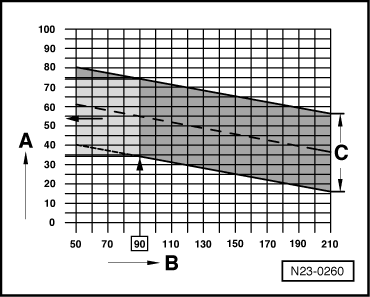

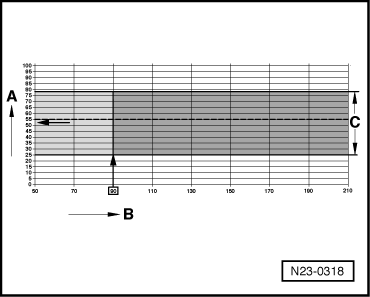

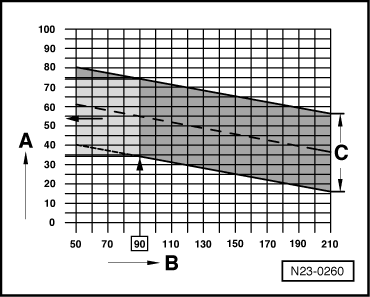

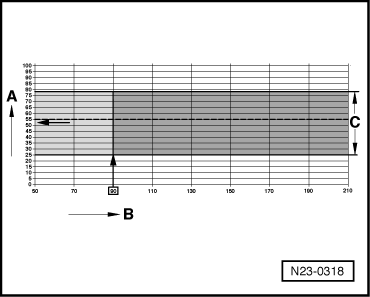

| A - display zone 2 commencement of injection B - display zone 9 fuel temperature C - specified value range for commencement of injection |

| Numerical value 90 in display zone 9 -B- corresponds to a numerical value range of 25..78 in display zone 2 -A-. |

| Continuation for all engine codes |

Note | If, when checking the commencement of injection, the specifications are within zone -C- then no readjustment is required. After repairs, e.g. removing and installing injection pump, adjusting timing, the commencement of injection must be set to the mean valve (dashed line) of specification zone -C-. |

| If the commencement of injection lies outside of the specification range, adjust commencement of injection as follows: |

| Engine codes AGR, AHF, ALH, ASV |

| –

| Remove connecting pipe between charge air cooler and intake manifold. |

| Continuation for all engine codes |

| –

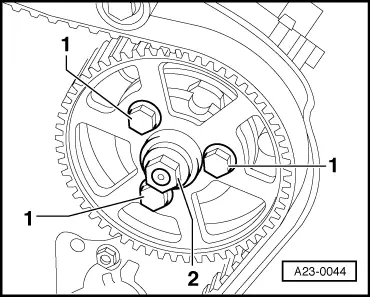

| Remove upper toothed belt guard. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note