Golf Mk4

| II - Repairing front drive shaft with constant velocity joint VL 3700 |

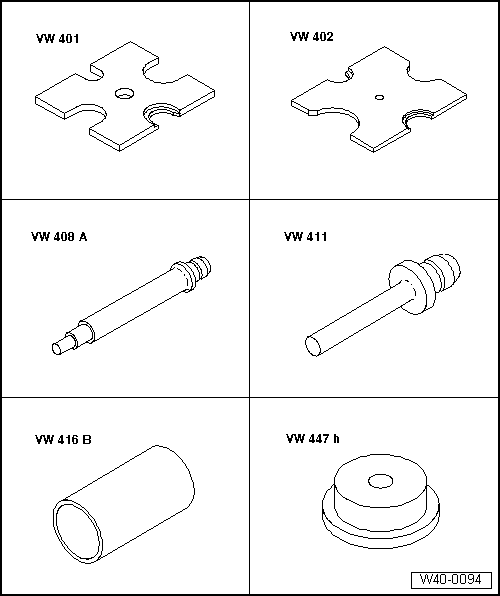

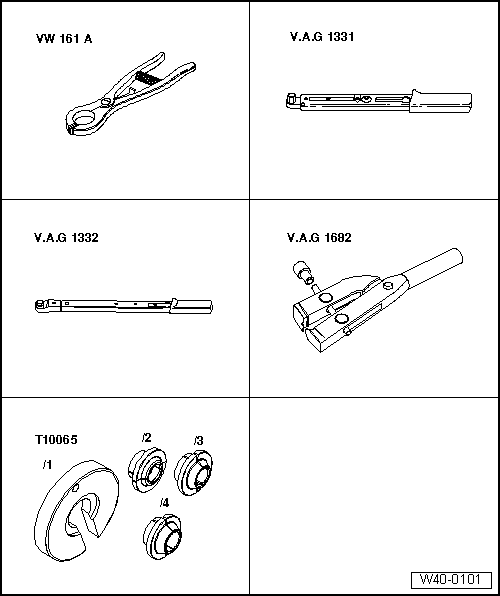

| Special tools and workshop equipment required |

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 411- |

| t | Tube -VW 416 B- |

| t | Thrust plate -VW 447 H- |

| t | Circlip pliers -VW 161 A- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Pliers -V.A.G 1682- |

| t | Assembly tool -T10065- |

|

| Grease | of which in: | ||

| Outer joint | Total quantity | Joint | Boot |

| Ø mm | [g] | [g] | [g] |

| 98 | 120 | 80 | 40 |

| Inner joint | |||

| Ø mm | |||

| 108 | 120 | 60 | 60 |

|

| 1 - | Self-locking 12-point nut |

| q | Tightening → Chapter. |

| q | Remove any corrosion on thread of outer joint before fitting nut. |

| q | Renew each time after removing. |

| 2 - | Outer constant velocity joint |

| q | Renew only complete. |

| q | Removing → Fig.. |

| q | Installing: drive onto shaft to stop using plastic mallet. |

| q | Checking → Chapter. |

| q | Greasing → . |

| 3 - | Hexagon bolt |

| q | Tightening → Chapter. |

| q | Remove any corrosion on thread of outer joint before fitting nut. |

| q | Renew each time after removing. |

| 4 - | Outer constant velocity joint |

| q | For special model “Golf GTI 132 kW” and “R32” only. |

| q | Renew only complete. |

| q | Removing → Fig.. |

| q | Installing: drive onto shaft to stop using plastic mallet. |

| q | Checking → Chapter. |

| q | Greasing → . |

| 5 - | Retaining ring |

| q | Renew. |

| q | Insert in groove in shaft. |

| 6 - | Thrust washer |

| q | Installation position → Fig.. |

| 7 - | Dished spring |

| q | Installation position → Fig.. |

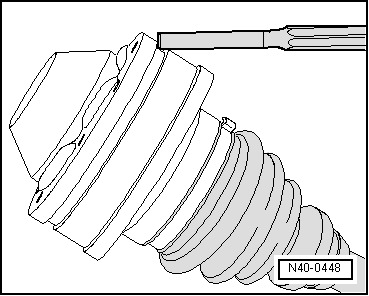

| 8 - | Clamp |

| q | Renew. |

| q | Tighten with pliers -V.A.G 1682- → Fig.. |

| 9 - | Boot |

| q | Check for splits and chafing. |

| q | Material: Hytrel (polyester elastomer). |

| 10 - | Clamp |

| q | Renew. |

| q | Tightening → Fig.. |

| 11 - | Drive shaft |

| 12 - | Boot for inner constant velocity joint |

| q | Material: rubber |

| q | With vent hole. |

| q | Check for splits and chafing, renew if necessary |

| 13 - | Clamp |

| q | Renew. |

| 14 - | Cap |

| q | Drive off with a drift. |

| q | Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing. |

| q | Adhesive surface must be free of oil and grease! |

| 15 - | Multi-point socket head bolt |

| q | Initially tighten diagonally to 10 Nm. |

| q | Tighten to 70 Nm. |

| q | Renew each time after removing. |

| 16 - | Locking plate |

| 17 - | Inner constant velocity joint |

| q | Renew only complete. |

| q | Pressing off → Fig.. |

| q | Pressing on → Fig.. |

| q | Checking → Chapter. |

| q | Adhesive surface must be free of oil and grease! |

| q | Greasing → . |

| 18 - | Retaining ring |

| q | Renew. |

| 19 - | Gasket |

| q | Renewing: pull off protective foil and stick onto joint. |

| 20 - | Cover |

| q | Drive off carefully with drift → Fig. |

| q | Adhesive surface must be free of oil and grease! |

| q | Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing. |

|

|