| For vehicles with twelve-point nut and hexagon bolt |

| Remove any residual paint and/or corrosion on thread and splines of outer joint. |

| Before installing drive shaft, lightly lubricate: |

| t

| splines on outer joint, |

| t

| contact surface and thread of 12-point nut |

| Vehicles with hexagon bolt |

Note | Do not oil hexagon bolt threads. |

| Continuation for all vehicles |

| –

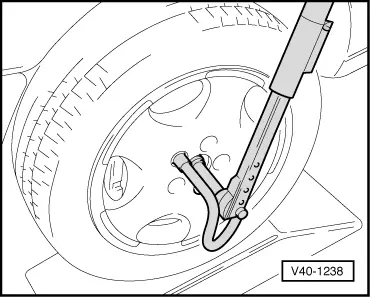

| Guide outer joint into wheel hub splines as far as possible. |

| –

| Bolt swivel joint to suspension link using new bolts on old impression marks. |

| Swivel joint to suspension link: 20 Nm + 90° further |

| –

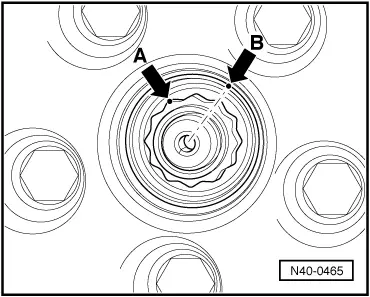

| Position drive shaft inner joint and tighten bolts diagonally to 10 Nm. |

|

|

|

Note

Note