Golf Mk5

|

Note

Note

|

|

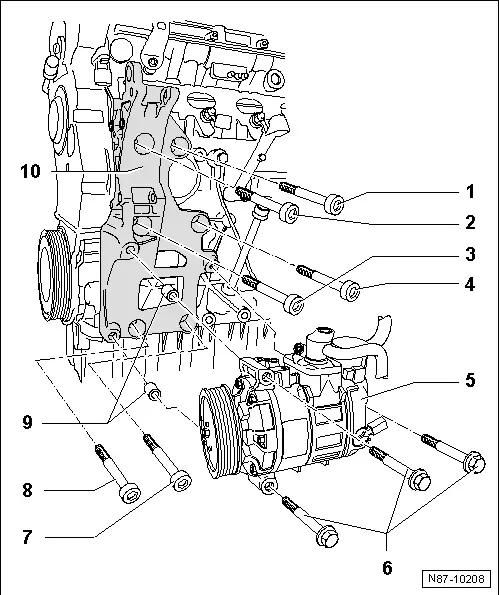

| 1 - | Socket head flange bolt M10×45 |

| q | Dowel hole |

| q | Observe different torques: |

| q | 1.6 l injection engine and 2.0 l FSI engine: 52 Nm |

| q | 2.0 l turbo FSI engine: 40 Nm |

| 2 - | Socket head flange bolt M10×45 |

| q | Observe different torques: |

| q | 1.6 l injection engine and 2.0 l FSI engine: 52 Nm |

| q | 2.0 l turbo FSI engine: 40 Nm |

| 3 - | Socket head flange bolt M10×45 |

| q | Observe different torques: |

| q | 1.6 l injection engine and 2.0 l FSI engine: 52 Nm |

| q | 2.0 l turbo FSI engine: 40 Nm |

| 4 - | Socket head flange bolt M10×45 |

| q | Observe different torques: |

| q | 1.6 l injection engine and 2.0 l FSI engine: 52 Nm |

| q | 2.0 l turbo FSI engine: 40 Nm |

| 5 - | Air conditioner compressor |

| q | Removing and installing → Chapter |

| 6 - | Hexagon bolt M8x100 |

| q | Qty. 3 |

| q | 25 Nm. |

| 7 - | Socket head flange bolt M10×45 |

| q | Dowel hole |

| q | Observe different torques: |

| q | 1.6 l injection engine and 2.0 l FSI engine: 52 Nm |

| q | 2.0 l turbo FSI engine: 40 Nm |

| 8 - | Socket head flange bolt M10×45 |

| q | Observe different torques: |

| q | 1.6 l injection engine and 2.0 l FSI engine: 52 Nm |

| q | 2.0 l turbo FSI engine: 40 Nm |

| 9 - | Dowel sleeves |

| q | Qty. 2 |

| q | Ensure proper seating between ancillary bracket and air conditioner compressor. |

| 10 - | Ancillary bracket for air conditioner compressor |

| Number on ancillary bracket -06F 903 143 E/F- |

| Removing |

| – | Remove alternator → Electrical system; Rep. gr.27. |

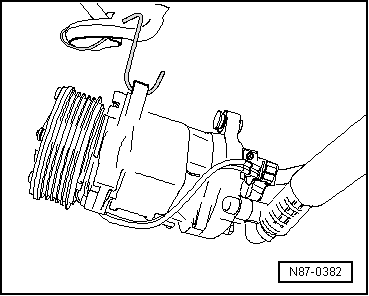

| – | Loosen air conditioner compressor and remove hexagon bolt -6-. Remove air conditioner compressor from ancillary bracket and secure to body with suitable material (e.g.welding wire) → Fig.. |

| – | Remove bolts -1- to -4-, -7- and -8- and remove ancillary bracket -10- from cylinder block. |

| Installing |

| t | Strictly observe tightening sequence of securing bolts: |

| – | Tighten socket head flange bolts, positions -1- (dowel hole), -7- (dowel hole), -4-, -8-, -3- and -2- one after the other. |

Note

Note

|

|