| –

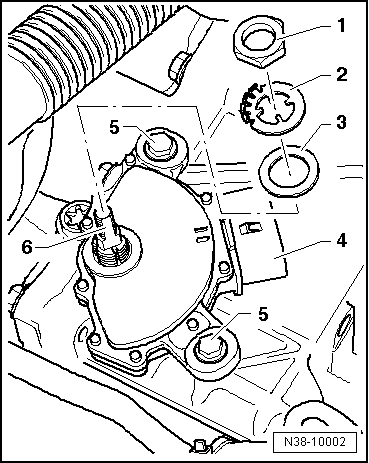

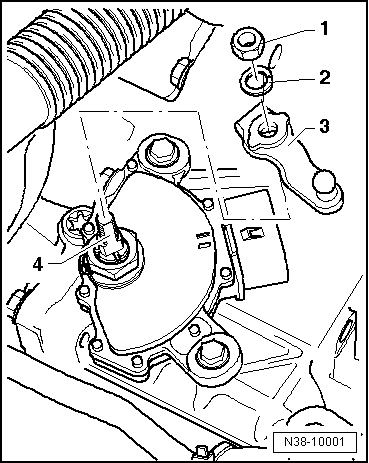

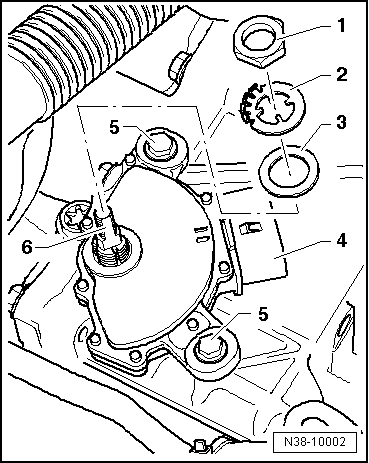

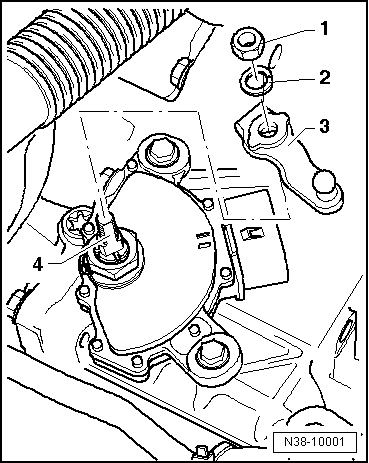

| Place multifunction switch -4- on selector shaft -6-. |

| –

| Tighten securing bolts -5- for multifunction switch hand-tight. |

| –

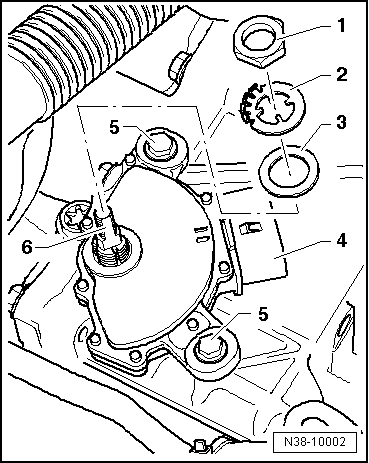

| Carefully bend back hooks of lock washer -2-. |

| –

| Put washers -2- and -3- on selector shaft -6-. |

| –

| Install washer -2- with hooks pointing up. |

| –

| Install washer -2- with long, narrow guides in long, narrow recesses of selector shaft -6-. |

| –

| Tighten nut -1- to 7 Nm. |

| –

| Secure nut -1- by bending up hooks on lock washer -2-. |

| –

| If hooks are broken off, renew lock washer. |

|

|

|