Golf Mk5

| Assembly overview - removing and installing cover for gearbox housing and 5th and 6th gears |

| 1 - | Gearbox housing |

| q | Pull off together with 5th and 6th gears → Chapter. |

| q | Repairing → Chapter. |

| 2 - | Gear wheel for 5th gear |

| q | Pull off individually → Chapter |

| q | Pull off together with gearbox housing → Chapter |

| 3 - | Sleeve |

| 4 - | Gear wheel for 6th gear |

| q | Pull off individually → Chapter |

| q | Pull off together with gearbox housing → Chapter |

| 5 - | Cylindrical roller bearing inner race |

| q | For output shaft |

| q | Mark before removing |

| q | Do not interchange with inner race for cylindrical roller bearing of input shaft |

| q | Larger outer diameter from gearbox date 21 08 6 |

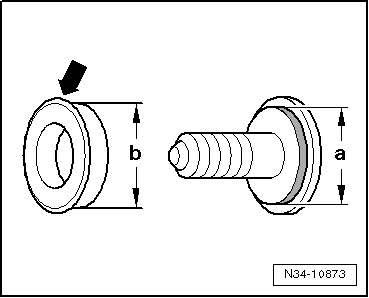

| q | Allocation → Fig. |

| 6 - | Bolt |

| q | For output shaft |

| q | Allocation of bolts → Fig. |

| q | To gearbox date 20 08 6: 40 Nm and 180° further |

| q | From gearbox date 21 08 6: 80 Nm and then turn 90° further |

| q | Self-locking |

| q | Always renew |

| q | Clean residual locking fluid from threaded holes for securing bolts for synchro-hub for 5th and 6th gears and gear wheel for 6th gear with a thread chaser. Otherwise the bolts may shear. |

| 7 - | Gearbox housing cover |

| q | With cylindrical roller bearings for input and output shafts |

| q | Cylindrical roller bearings for input and output shafts from gearbox date 21 08 6 with larger outer diameter → Fig. |

| q | Repairing → Chapter. |

| 8 - | Bolt, 18 Nm |

| q | Qty. 5 |

| q | For gearbox housing cover. |

| 9 - | Bolt |

| q | For input shaft |

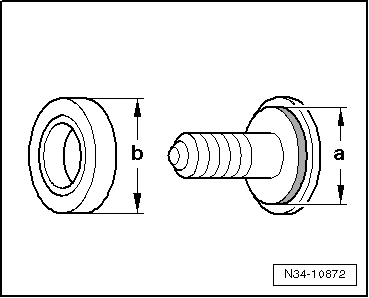

| q | Allocation of bolts → Fig. |

| q | To gearbox date 20 08 6: 40 Nm and 180° further |

| q | From gearbox date 21 08 6: 80 Nm and then turn 90° further |

| q | Self-locking |

| q | Always renew |

| q | Clean residual locking fluid from threaded holes for securing bolts for synchro-hub for 5th and 6th gears and gear wheel for 6th gear with a thread chaser. Otherwise the bolts may shear. |

| 10 - | Cylindrical roller bearing inner race |

| q | For input shaft |

| q | Mark before removing |

| q | Do not interchange with cylinder roller bearing inner race of output shaft. |

| q | From gearbox date 21 08 6, combined with thrust washer in one component → Item |

| q | Allocation of inner race for cylindrical roller bearing → Fig. |

| 11 - | Thrust washer |

| q | Through gearbox date 20 08 6 |

| 12 - | Inner race for cylindrical roller bearing with thrust washer |

| q | For input shaft |

| q | From gearbox date 21 08 6 |

| q | Allocation of inner race for cylindrical roller bearing → Fig. |

| 13 - | Sleeve |

| q | For 6th gear needle bearing. |

| q | Renew together with needle bearing |

| q | Larger diameter from gearbox date 21 08 6 |

| q | Allocation of components via → Electronic parts catalogue (ETKA) |

| 14 - | Needle bearing |

| q | For 6th gear |

| q | Renew together with sleeve |

| q | Larger diameter from gearbox date 21 08 6 |

| q | Allocation of components via → Electronic parts catalogue (ETKA) |

| 15 - | Synchromeshed gear for 6th gear |

| q | Adapted to sleeve and needle bearing from gearbox date 21 08 6 |

| q | Allocation of components via → Electronic parts catalogue (ETKA) |

| 16 - | Wave spring washer |

| q | From gearbox date 26 05 8 |

| q | In this case, install only locking piece springs without angled ends. (As shown in → Fig. - item 1-) |

| q | Allocate according to → Electronic parts catalogue „ETKA“ |

| 17 - | Synchro-ring for 6th gear |

| 18 - | Locking collar with synchro-hub for 5th and 6th gears |

| q | Pull off individually → Chapter |

| q | Pull off together with gearbox housing → Chapter |

| q | Dismantling and assembling → Fig. and → Fig. |

| q | From gearbox date 12 06 6, locking collar modified → Fig. |

| q | Adjusting, through gearbox date 11 06 6 → Fig. |

| q | Adjusting, from gearbox date 12 06 6 → Fig. |

| q | Installation of springs with angled ends for locking pieces → Fig. |

| 19 - | Synchro-ring for 5th gear |

| q | Will be damaged during removal of input shaft |

| q | Always renew |

| 20 - | Wave spring washer |

| q | From gearbox date 26 05 8 |

| q | In this case, install only locking piece springs without angled ends. (As shown in → Fig. - item 1-) |

| q | Allocate according to → Electronic parts catalogue „ETKA“ |

| 21 - | Synchromeshed gear for 5th gear |

| 22 - | Needle bearing |

| q | For 5th gear |

| 23 - | Socket head bolt, 25 Nm |

| q | For pivot pin to gearbox housing |

| 24 - | Pivot pin |

| 25 - | 5th/6th gear selector fork |

| 26 - | Selector jaw for 5th and 6th gears |

| 27 - | Bolt, 25 Nm |

|

|

| Gearbox manufacture date | Dim. „a“ mm | Dim. „b“ mm | ||

| Through 20 08 6 | 21 | 31 | ||

| From 21 08 6 | 23.4 | 37

|

|

|

| Gearbox manufacture date | Dim. „a“ mm | Dim. „b“ mm |

| Through 20 08 6 | 21 | 31 |

| From 21 08 6 | 23.4 | 37 |