Golf Mk5

|

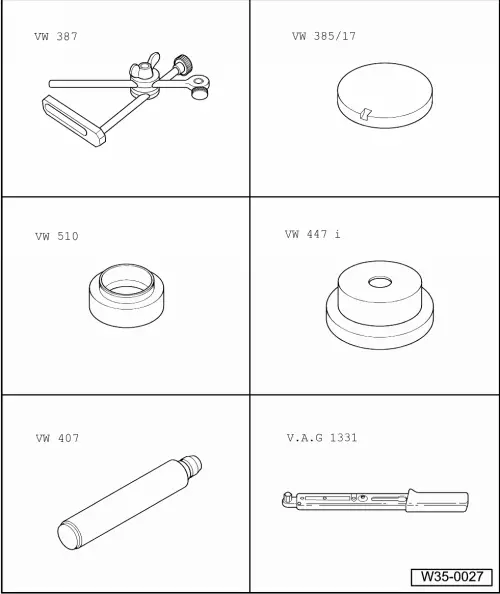

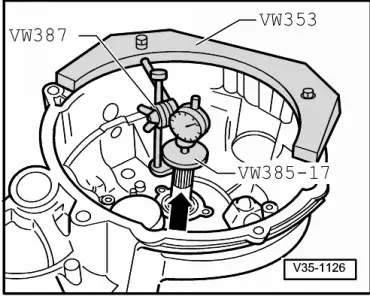

| Special tools and workshop equipment required |

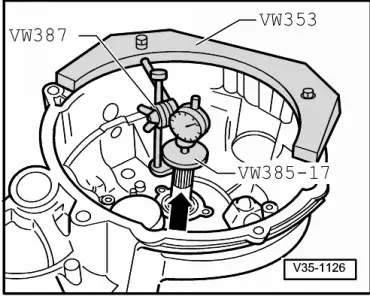

| t | Universal dial gauge bracket -VW 387- |

| t | End dimension plate -VW 385/17- |

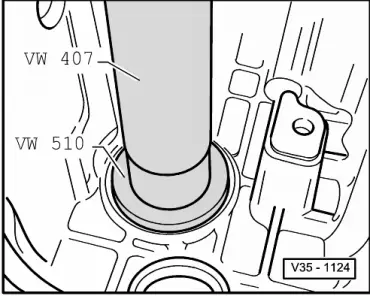

| t | Thrust pad -VW 510- |

| t | Thrust pad -VW 447 i- |

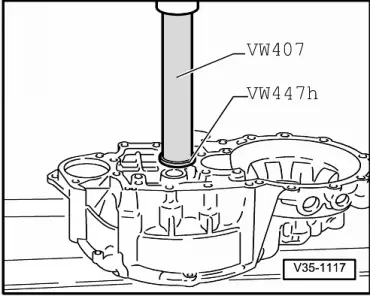

| t | Press tool -VW 407- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|