| –

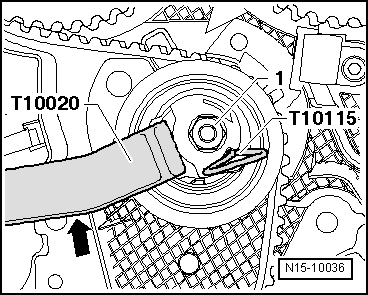

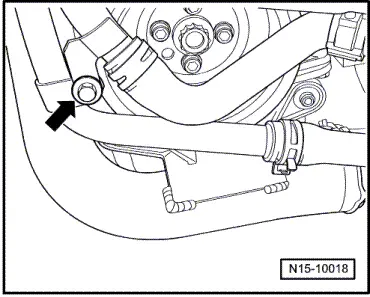

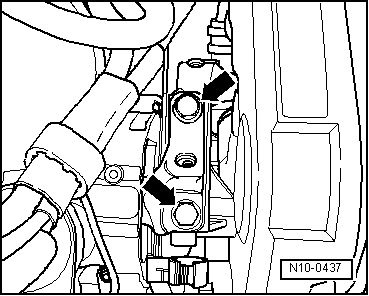

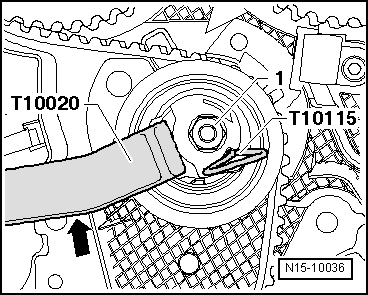

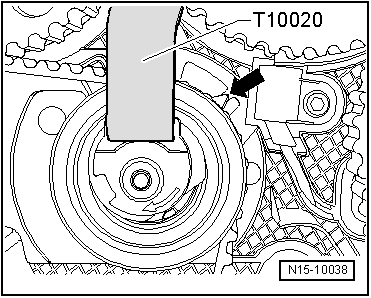

| Now turn pin-wrench clockwise to stop and tighten securing nut -1- hand-tight. |

| –

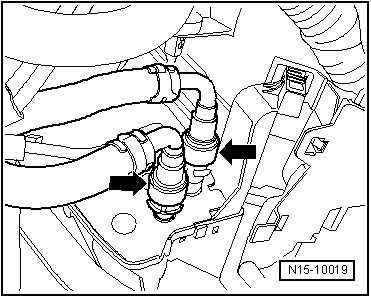

| Remove engine support downwards. |

| –

| Remove toothed belt first from coolant pump and then from remaining pulleys. |

Caution | Strictly follow the procedure described here. If, for example, the final check is not performed and the locking tool is not fitted again, there is a danger that the timing is not correctly adjusted and the vehicle will exhibit engine running problems and rough idling. |

|

Note | t

| Adjustment work on toothed belts must be performed only on cold engines, as the indicator position on the tensioning element varies depending on the engine temperature. |

| l

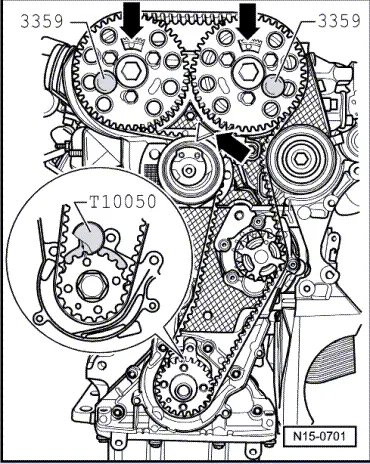

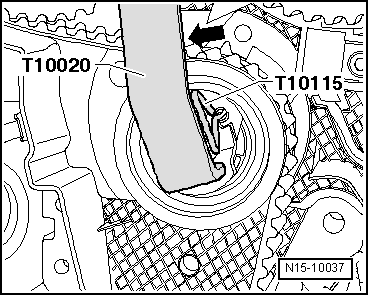

| Tensioning roller must be locked with locking pin -T10115- and secured to right stop. |

| l

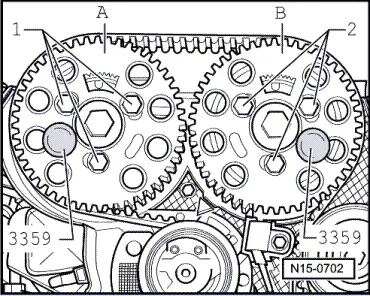

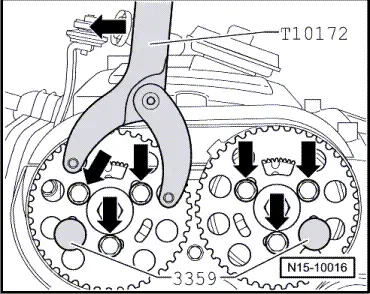

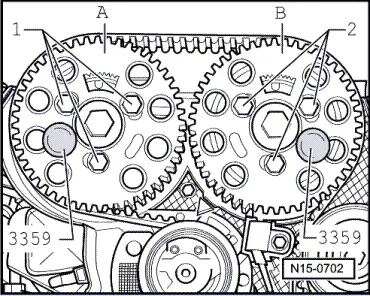

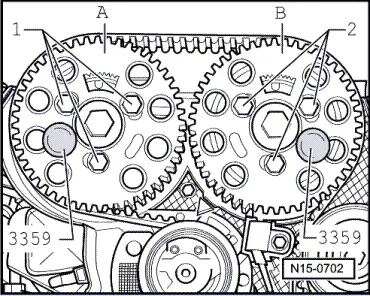

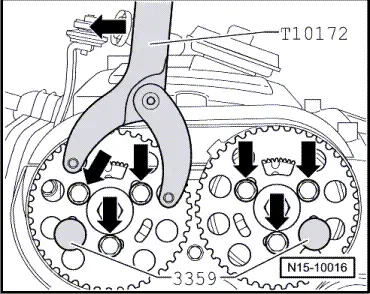

| Camshafts are locked using diesel injection pump locking pin -3359-. |

| l

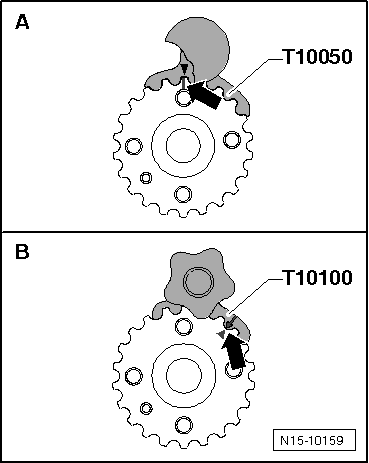

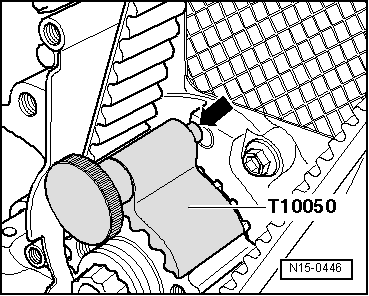

| Crankshaft is locked using crankshaft stop -T10050 bzw. T10100-. |

| –

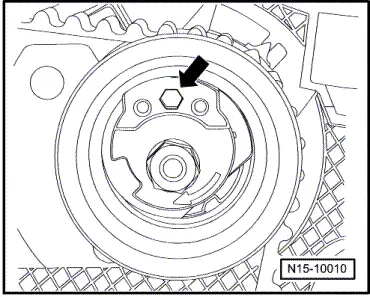

| Turn camshaft pulleys in their elongated holes clockwise to stop. |

| –

| Fit toothed belt to crankshaft pulley, tensioning roller and camshaft pulley and idler roller. |

| –

| Then fit toothed belt on coolant pump toothed belt pulley. |

| –

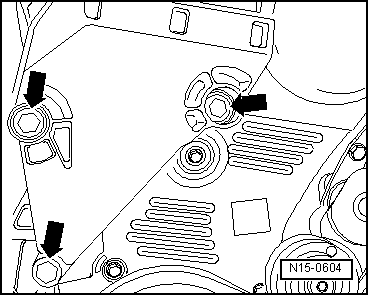

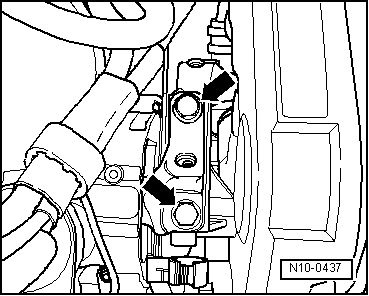

| Install engine support from below and insert lower securing bolt. |

| –

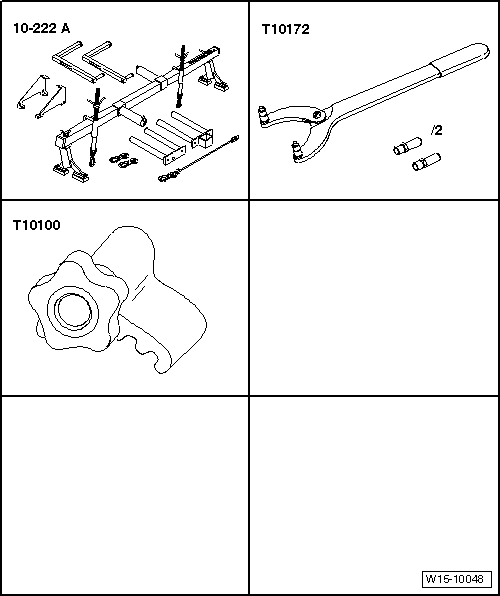

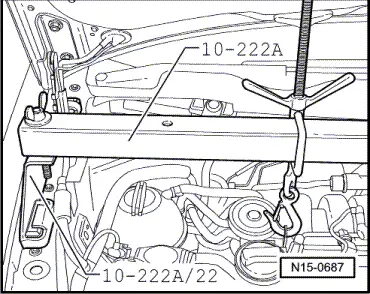

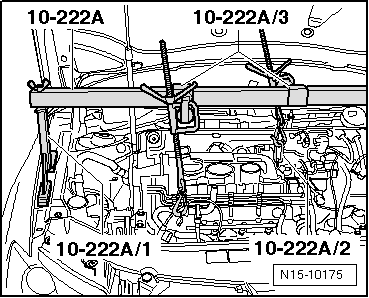

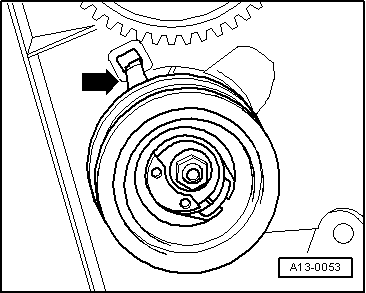

| Raise engine with support bracket -10-222A- until indicator of tensioning roller can be seen. |

| –

| Loosen tensioning roller securing nut and pull out locking pin -T10115-. |

Note |

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution