Golf Mk5

Note

Note

|

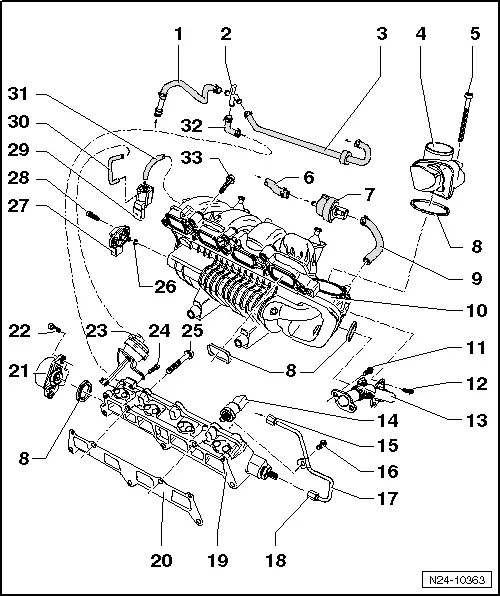

| 1 - | Supply line |

| q | Secure with spring-type clips. |

| q | Check for secure seating. |

| q | From fuel filter. |

| 2 - | T piece |

| 3 - | Fuel line |

| q | Pipe/hose |

| 4 - | Throttle valve module -J338- |

| q | Clean → Chapter. |

| q | If renewed, erase learnt values and adapt engine control unit → Vehicle diagnostic, testing and information system VAS 5051„Guided functions“. |

| 5 - | 10 Nm |

| 6 - | From activated charcoal filter |

| 7 - | Activated charcoal filter solenoid valve 1 -N80- |

| 8 - | Seal |

| q | Renew. |

| q | Press in onto stop |

| 9 - | From activated charcoal filter system solenoid valve 1 -N80- |

| 10 - | Intake manifold |

| q | Checking vacuum reservoir in intake manifold → Chapter. |

| 11 - | 8 Nm |

| 12 - | 5 Nm |

| 13 - | Connecting pipe |

| q | For exhaust gas recirculation system. |

| 14 - | Fuel pressure sender -G247-, 20 Nm |

| q | Observe safety precautions when releasing fuel pressure in high-pressure section → Chapter |

| 15 - | Union nut, 30 Nm |

| 16 - | 8 Nm |

| 17 - | High-pressure line |

| q | Observe safety precautions when releasing fuel pressure in high-pressure section → Chapter |

| 18 - | Union nut, 25 Nm |

| 19 - | Fuel rail |

| q | Observe safety precautions when releasing fuel pressure in high-pressure section → Chapter |

Caution

Caution

|

| q | Erase learnt values and adapt intake manifold flap potentiometer -G336- to engine control unit → Vehicle diagnostic, testing and information system VAS 5051„Guided functions“. |

| q | Before removing and installing, lock vacuum positioning element using a 2.5 mm drill bit. |

| q | After installing a new fuel rail, remove retaining clip for vacuum positioning element. |

| q | After installing, check function of intake manifold flap using hand vacuum pump -VAS 6213- → Chapter. |

| 20 - | Gasket |

| q | Renew. |

| q | Note installation position. |

| 21 - | Intake manifold flap potentiometer -G336- |

| q | If renewed, erase learnt values and adapt engine control unit → Vehicle diagnostic, testing and information system VAS 5051„Guided functions“. |

| 22 - | 1.5 Nm |

| 23 - | Vacuum actuator |

| q | For intake manifold flap |

| q | Check → Chapter. |

| 24 - | 2.2 Nm |

| 25 - | 20 Nm |

| 26 - | O-ring |

| q | Renew. |

| 27 - | Intake manifold pressure sender -G71- |

| 28 - | 5 Nm |

| 29 - | Intake manifold flap air flow control valve -N316- |

| 30 - | Vacuum hose |

| q | To vacuum positioning element |

| 31 - | Vacuum hose |

| q | From intake manifold |

| 32 - | Return hose |

| q | From fuel rail. |

| q | Secure with spring-type clips. |

| q | Check for secure seating. |

| 33 - | 20 Nm |

WARNING

WARNING