Golf Mk5

| Adjusting vacuum unit for turbocharger |

| Special tools and workshop equipment required |

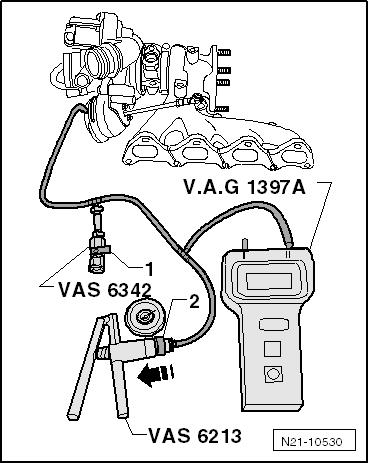

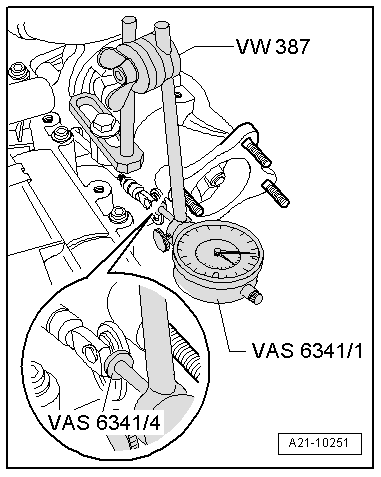

| t | Universal dial gauge bracket -VW 387- |

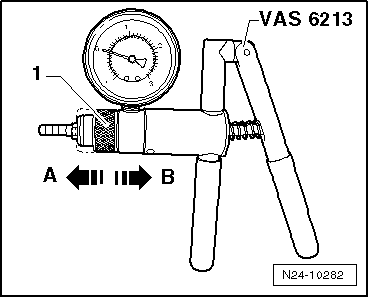

| t | Hand vacuum pump -VAS 6213- |

| t | Pressure regulating valve -VAS 6342- |

| t | Turbocharger tester -V.A.G 1397A- |

| t | Dial gauge set, 4-part -VAS 6341- |

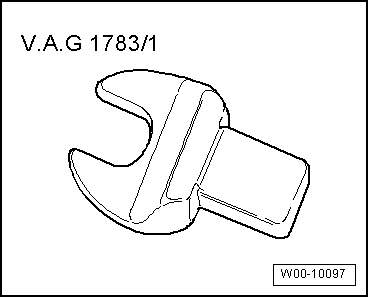

| t | Torque wrench -V.A.G 1783- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution