| –

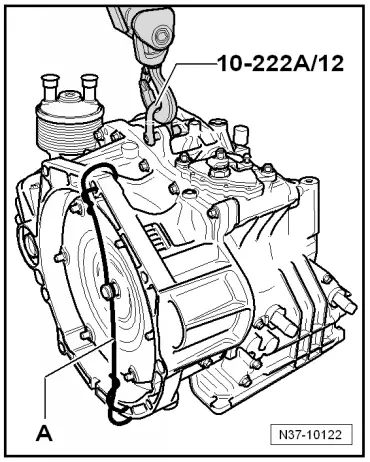

| Secure gearbox to workshop crane with shackle -10 - 222 A /12-, but do not raise. |

| –

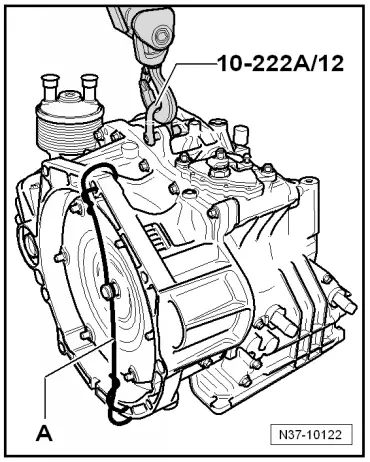

| Remove upper engine/gearbox securing bolts. |

| –

| Before now removing the final securing bolts, support gearbox with workshop crane. |

| –

| Remove lower engine/gearbox securing bolts. |

| –

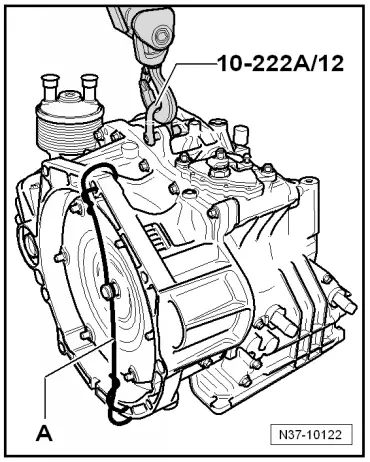

| Press gearbox off from engine, guiding the gearbox |

| Insert tool -T10035- also facilitates assembly. |

| –

| Leave an easily accessible bolt installed for safety purposes. |

| –

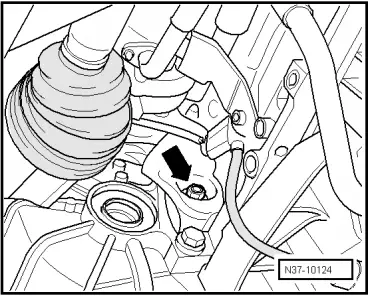

| Start with the two lower bolts. |

| The hole for removing the converter nuts is covered with a rubber cap on the rear of the engine. |

|

|

|

Note

Note Note

Note