| t

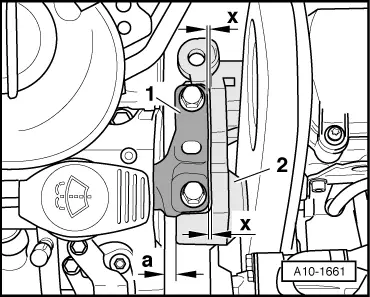

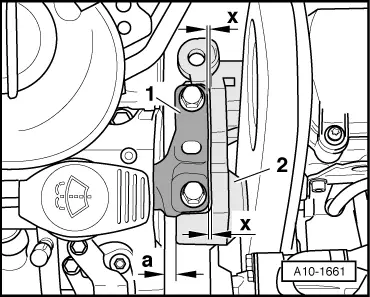

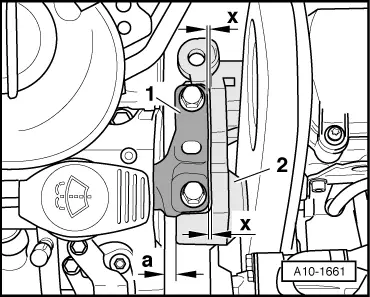

| There must be a distance of -a- at least 10 mm between engine bracket and longitudinal member (right side). |

| t

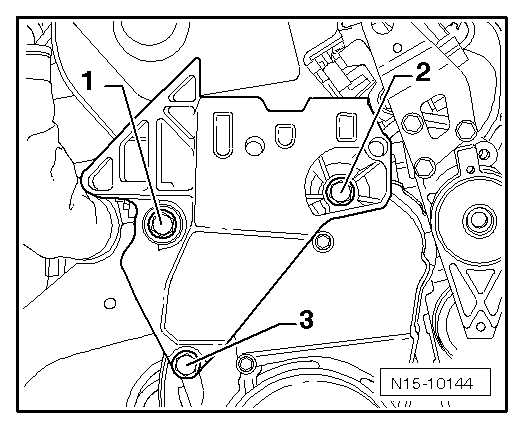

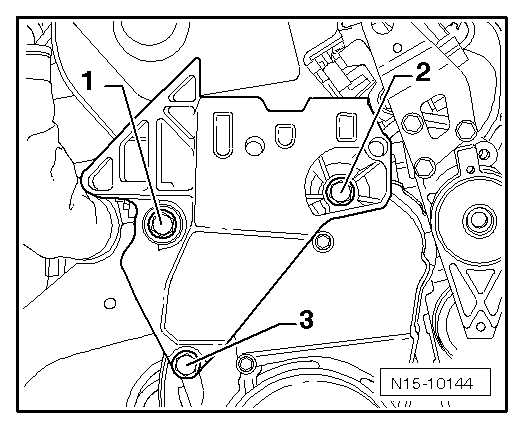

| The side surface of the engine bracket -2- should be located parallel to the support arm -1-. |

| –

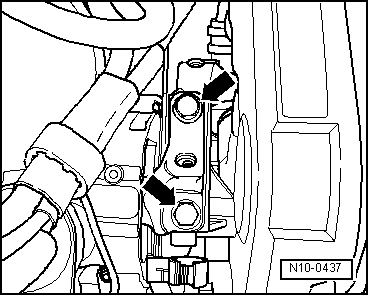

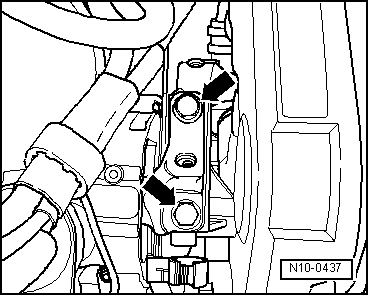

| Tighten bolts for engine assembly mounting and engine bracket. Specified torques: → Chapter. |

| –

| Remove support bracket -10 - 222 A-. |

| –

| Install poly V-belt tensioner. |

| –

| Reconnect fuel and breather lines. Ensure that push-on connectors are properly secured. |

| –

| Install coolant expansion tank and activated charcoal filter. |

| –

| Resecure pendulum support to gearbox. Specified torques → Fig. |

| –

| Refit fuse SC27 (Golf Plus SC47) in fuse holder. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note