Golf Mk5

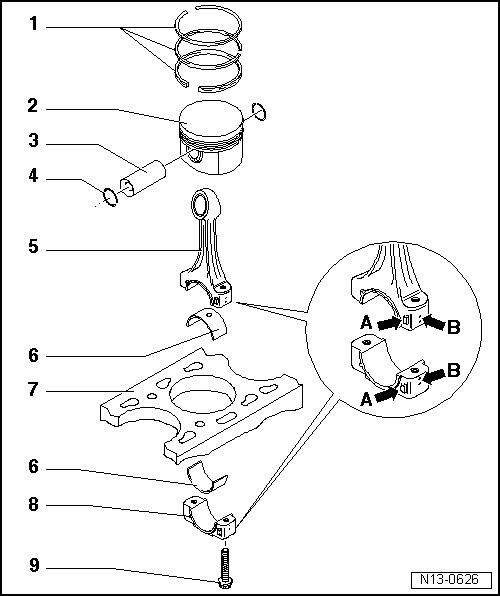

| Industrially cracked conrods |

| 1 - | Piston rings |

| q | Offset gaps by 120° |

| q | Remove and install using piston ring pliers |

| q | “TOP” faces towards piston crown |

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |

| 2 - | Piston |

| q | Checking → Fig. |

| q | Mark installation position and cylinder number |

| q | Arrow on piston crown points to pulley end |

| q | Install using piston ring clamp |

| 3 - | Piston pin |

| q | If difficult to remove, heat piston to 60° C |

| q | Remove and install with drift -VW 222A- |

| 4 - | Circlip |

| 5 - | Conrod |

| q | With industrially cracked bearing caps |

| q | Renew as set only |

| q | Mark cylinder number -B- |

| q | Installation position: marking -A- faces towards pulley end |

| 6 - | Bearing shell |

| q | Note installation position → Fig. |

| q | Insert bearing shells centrally |

| q | Do not interchange used bearing shells |

| q | Check for secure seating |

| q | Axial clearance new: 0.10...0.35 mm, wear limit: 0.4 mm |

| q | Check radial clearance with Plastigage: new: 0.01...00.05 mm, wear limit: 0.12 mm. Do not rotate crankshaft when checking radial clearance |

| 7 - | Cylinder block |

| q | Checking cylinder bores → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| 8 - | Conrod bearing cap |

| q | Note installation position |

| q | The caps only fit in one position and only on the appropriate conrod due to the breaking procedure (cracking) separating the cap from the conrod |

| 9 - | Bolt |

| q | 30 Nm + 1/4 turn (90 °) further |

| q | Torx T10 |

| q | Renew |

| q | Oil threads and contact surface |

| q | To measure radial clearance, tighten to 30 Nm but not further |