Golf Mk5

|

|

|

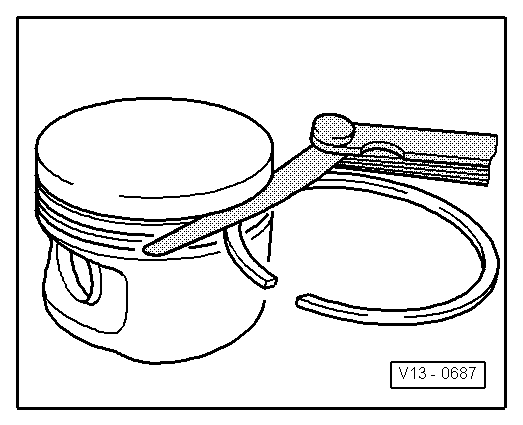

| Piston ring | Gap | ||

| New | Wear limit | ||

| Compression rings (top) | mm | 0.15…0.35 | 0.8 |

| Compression rings (bottom) | mm | 0.40...0.40 | 0.8 |

| Oil scraper ring | mm | 0.20…0.70 | 0.9 |

|

|

| Piston ring | Ring-to-groove clearance | ||

| New | Wear limit | ||

| Top compression rings | mm | 0.04…0.075 | 0.15 |

| Middle compresion rings | mm | 0.02...0.055 | 0.15 |

| Oil scraper ring | mm | 0.05…0.13 | 0.20 |

|

|

Note

Note

|

|