Golf Mk5

| Removing and installing anti-roll bar |

| Special tools and workshop equipment required |

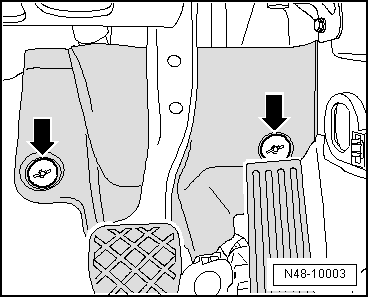

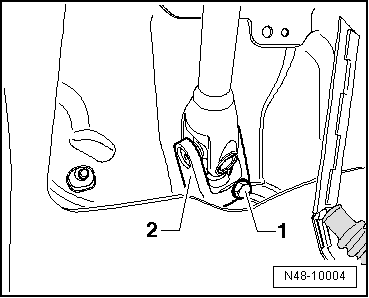

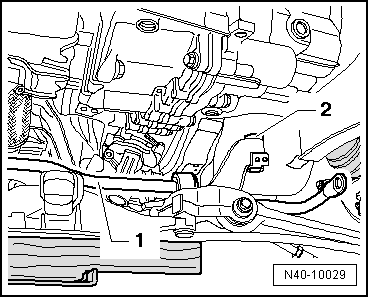

| t | Locating pins -T10096- |

| t | Torque wrench -V.A.G 1332- |

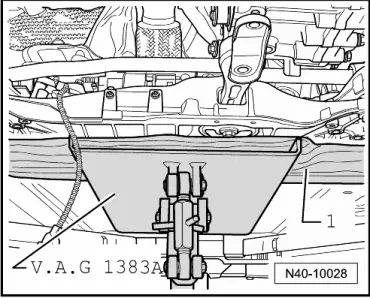

| t | Engine and gearbox jack -V.A.G 1383 A- |

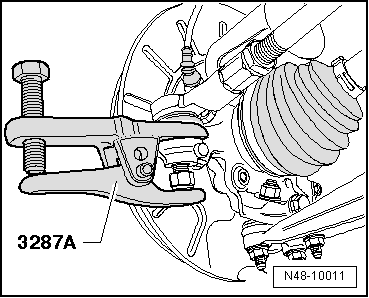

| t | Ball joint puller -3287 A- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Specified torques |

| Component | Specified torque | ||||

Subframe to body

| 70 Nm + 90° | ||||

Bracket to body

| 70 Nm + 90° | ||||

Mounting bracket to body

| 70 Nm + 90° | ||||

Subframe to bracket

| 70 Nm + 90° | ||||

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

Anti-roll bar to coupling rod

| 65 Nm | ||||

Anti-roll bar to subframe

| 20 Nm + 90° | ||||

Suspension link to bracket

| 70 Nm + 180° | ||||

Steering box to subframe

| 50 Nm + 90° | ||||

Universal joint to steering box

| 30 Nm |

| Specified torques for pendulum support to gearbox |

Caution

Caution

|

| Bolt | Specified torque | ||

M10 x 35 strength class 8.8

| 40 Nm + 90° further | ||

M10 x 35 strength class 10.9

| 50 Nm + 90° further | ||

M10 x 75 strength class 8.8

| 40 Nm + 90° further | ||

M10 x 75 strength class 10.9

| 50 Nm + 90° further |

|