Golf Mk5

| Repairing subframe (front-wheel drive) |

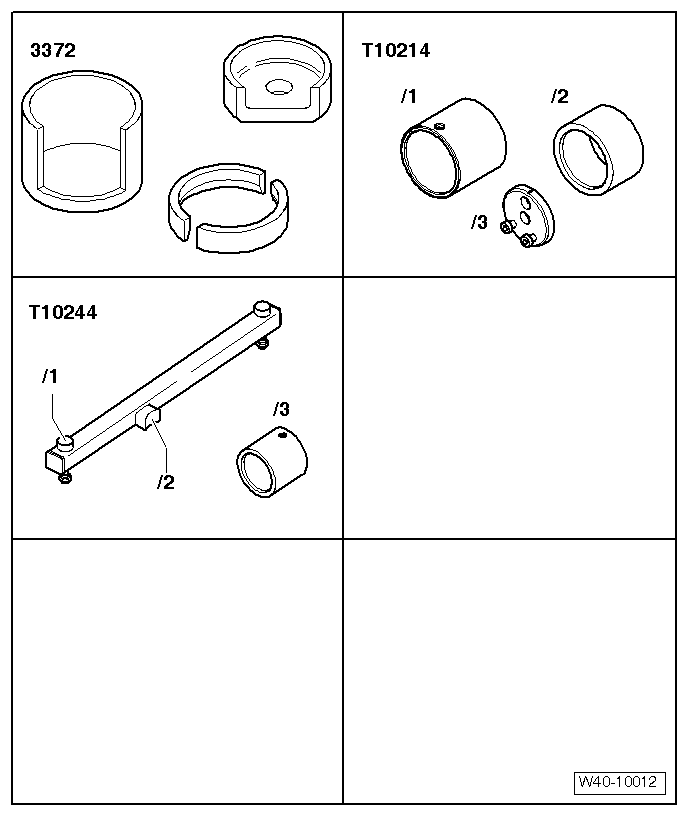

| Special tools and workshop equipment required |

| t | Removal tool -3372- |

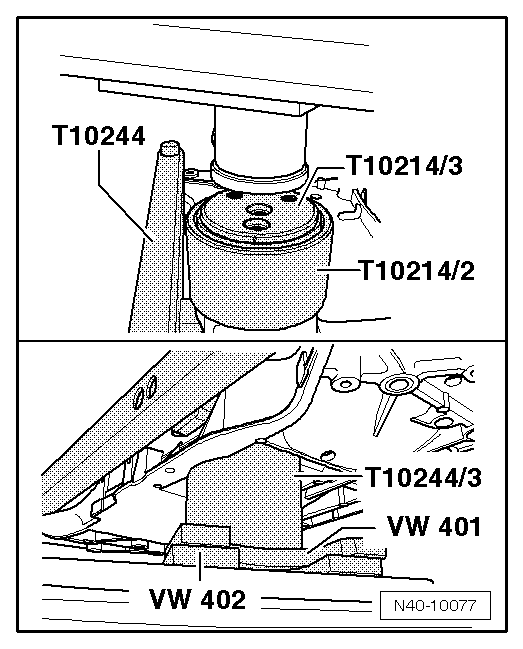

| t | Assembly tool -T10214- |

| t | Assembly tool -T10244- |

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|