Golf Mk5

| Removing and installing steering box, left-hand drive vehicle (1st and 2nd generations) up to model year 2008 |

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

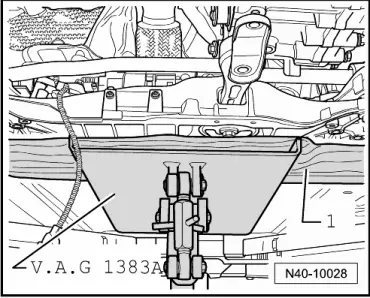

| t | Engine and gearbox jack -V.A.G 1383 A- |

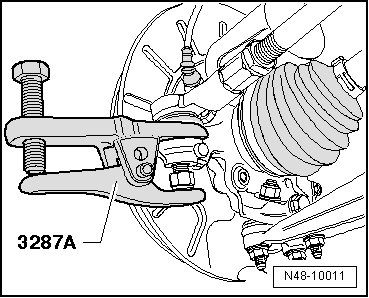

| t | Ball joint puller -3287 A- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

| Specified torques |

| Component | Specified torque | ||||

Subframe to body

| 70 Nm + 90° | ||||

Anti-roll bar to subframe

| 20 Nm + 90° | ||||

Anti-roll bar to coupling rod

| 65 Nm | ||||

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

Shield to subframe

| 6 Nm | ||||

Steering box to subframe

| 50 Nm + 90° | ||||

Universal joint to steering box

| 30 Nm | ||||

Shield to steering box

| 6 Nm | ||||

Track rod ball joint to wheel bearing housing

| 20 Nm + 90° | ||||

| Exhaust system bracket to subframe → Engine; Rep. gr.26 | |||||

| Specified torques for pendulum support to gearbox |

Caution

Caution

|

| Bolt | Specified torque | ||

M10 x 35 strength class 8.8

| 40 Nm + 90° further | ||

M10 x 35 strength class 10.9

| 50 Nm + 90° further | ||

M10 x 75 strength class 8.8

| 40 Nm + 90° further | ||

M10 x 75 strength class 10.9

| 50 Nm + 90° further |