Golf Mk6

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

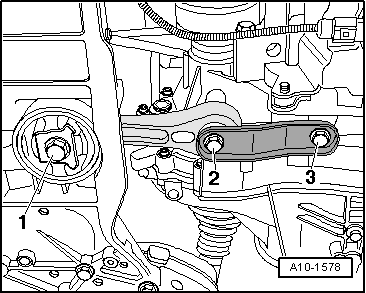

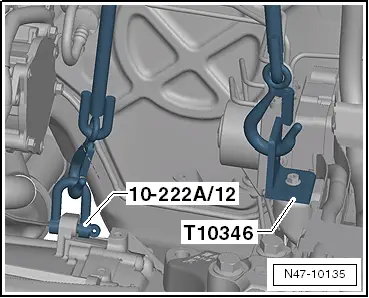

| – | Fit support bracket -10 - 222 A- and support engine/gearbox assembly. |

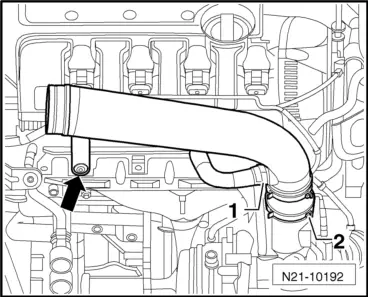

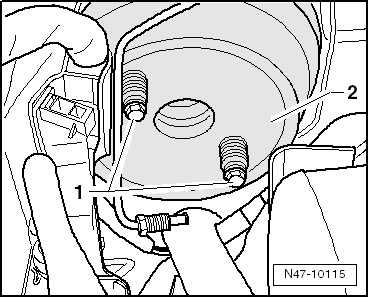

| – | Mount adapter -10 - 222 A /8- on the longitudinal beams directly before the projection -arrow 1- and next to the bolt -arrow 2-. |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING