| Assembling 5th gear locking collar/synchro-hub |

| –

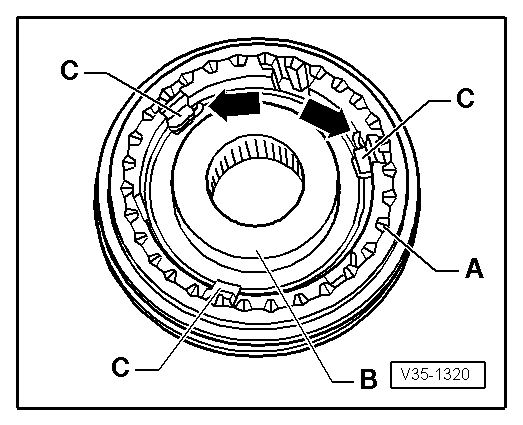

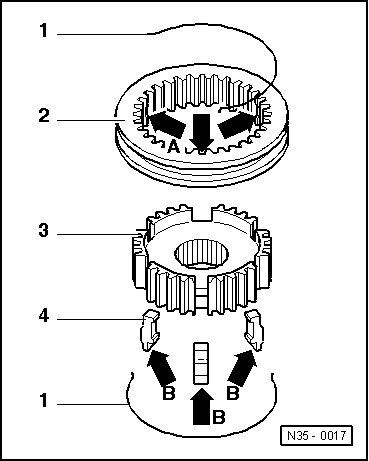

| Slide locking collar over synchro-hub. |

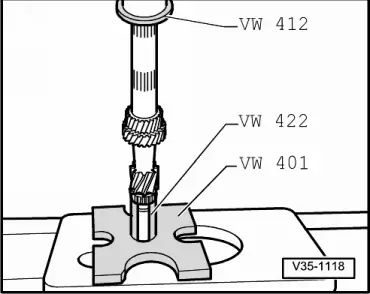

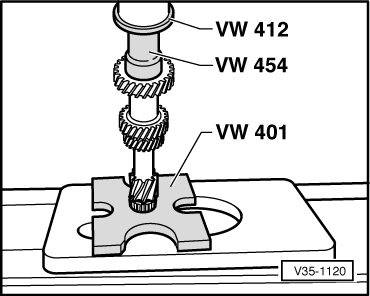

| Pointed teeth -A- and shoulder -B- of synchro-hub face in same direction. The recesses for the locking pieces in locking collar and synchro-hub must be aligned ( → Fig.). |

| –

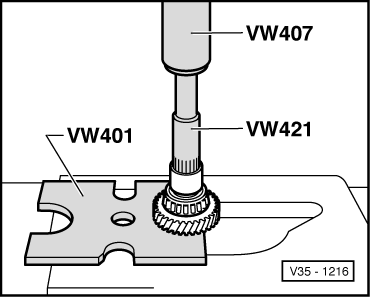

| Insert locking pieces (installation position → Fig.). |

| –

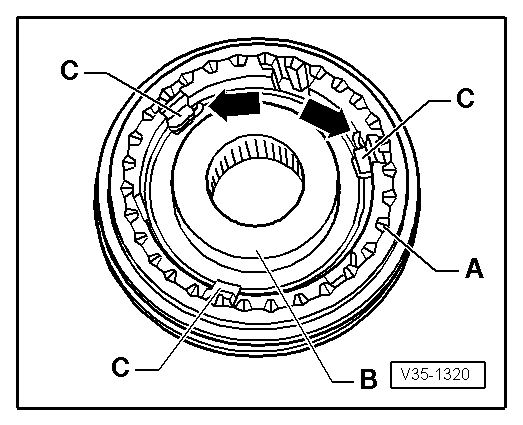

| Install springs below shoulder -C- of the locking piece, offset 120°. |

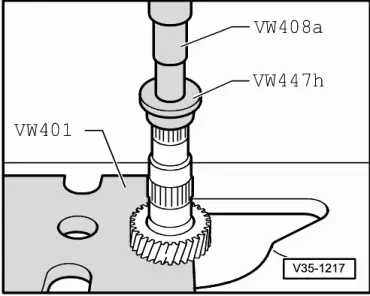

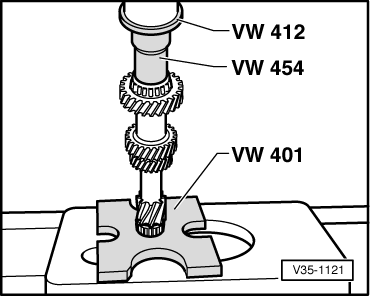

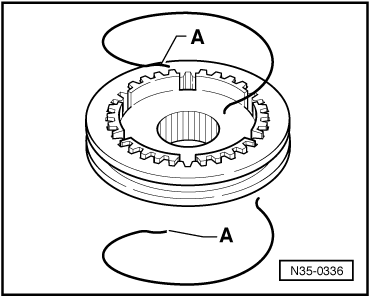

| Installation positions of springs if locking pieces are not hollow: |

| Spring must seat with angled end in front of locking piece -arrows-. |

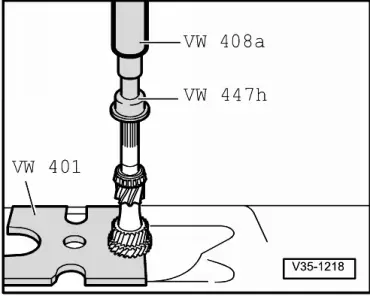

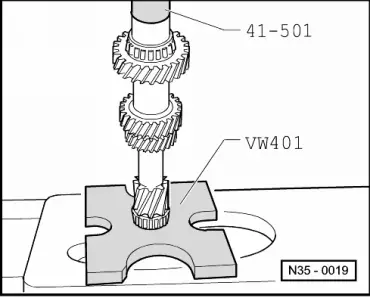

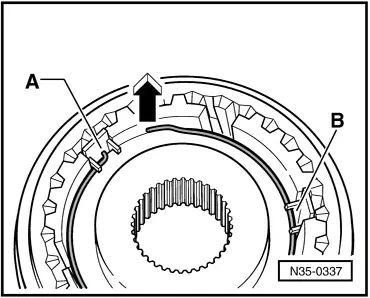

| Installation positions of springs if locking pieces are hollow: |

| –

| Angled end of spring must locate in hollow locking piece (⇒ second figure below). |

|

|

|