Golf Mk6

| Dismantling and assembling input shaft |

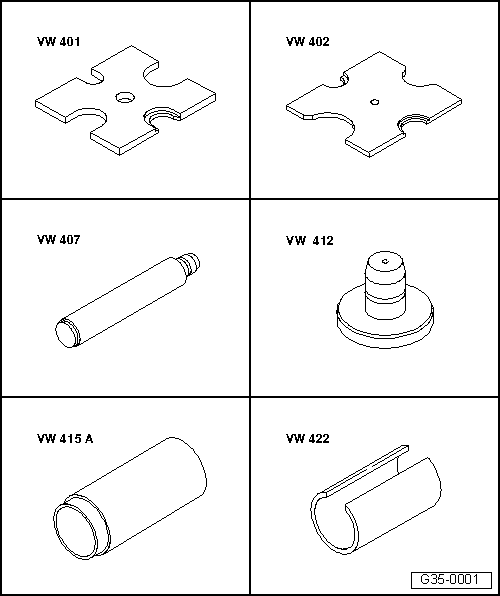

| Special tools and workshop equipment required |

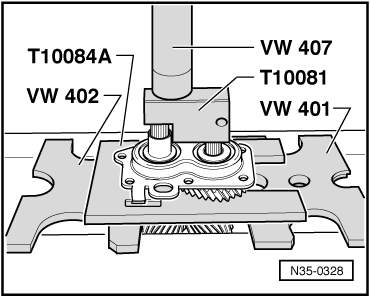

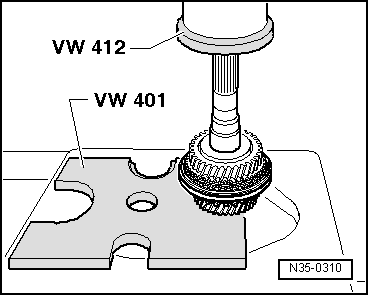

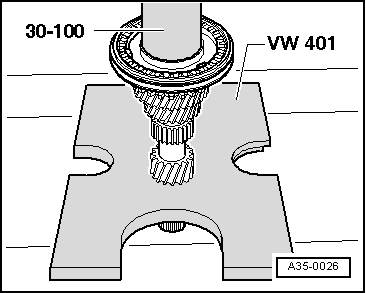

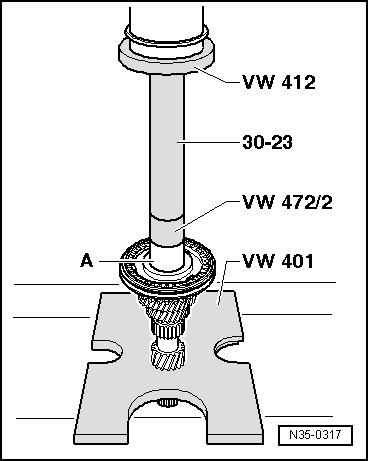

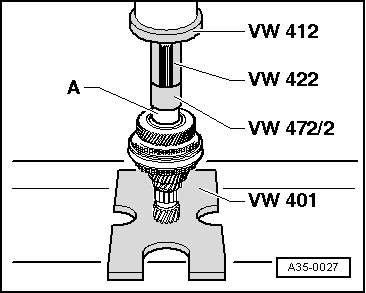

| t | Pressure plate -VW 401- |

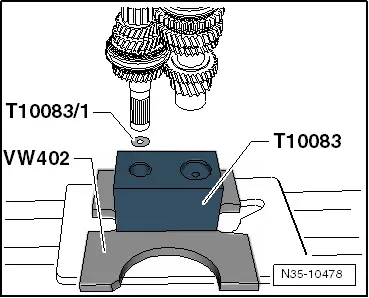

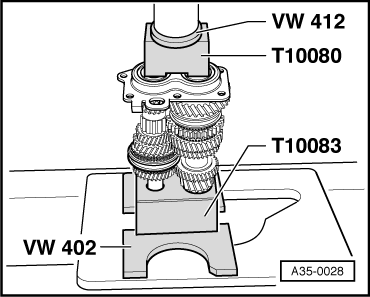

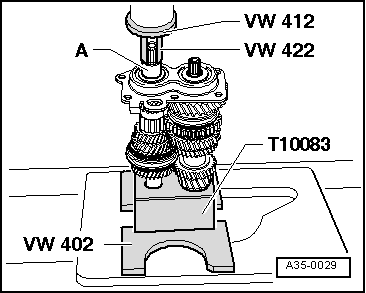

| t | Pressure plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Tube -VW 422- |

| t | Spacer sleeve -VW 472/2- |

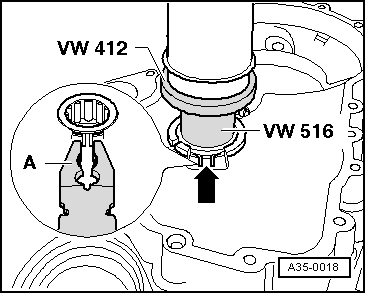

| t | Tube -VW 516- |

| t | Drift sleeve -30 - 23- |

| t | Drift sleeve -30 - 100- |

| t | Thrust piece -T10080- |

| t | Thrust piece -T10081- |

| t | Circlip pliers -VW 161 A- |

| t | Tube -2010- |

| t | thrust piece -T10083- |

| t | Washer -T10083/1- |

| t | Pressure plate -T10084A- |

| t | -1-Internal puller -Kukko 21/5- |

| t | -4-Counter support -Kukko 22/2- |

| t | -Fühlerblattlehre- |

Note

Note| t | When installing new gear wheels or input shaft, consult technical data and → Electronic parts catalogue „ETKA“. |

| t | Install all bearings, synchromeshed gears and synchro-rings on input shaft with gear oil. |

| t | Do not interchange synchro-rings. When reusing always fit to the original gear. |

| 1 - | Retaining ring |

| q | Always renew |

| q | Determining thickness → Anchor |

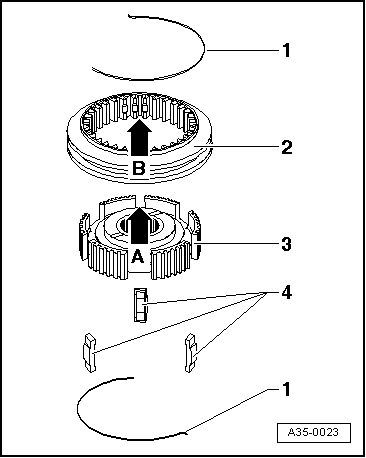

| 2 - | 5th gear locking collar with synchro-hub |

| q | Removing and installing → Chapter |

| q | Dismantling → Fig. |

| q | Assembling 5th gear locking collar and synchro-hub → Fig.. |

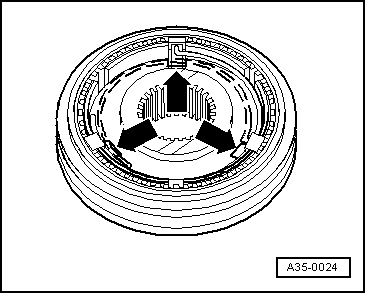

| q | Installation position → Fig. |

| 3 - | Synchro-ring for 5th gear |

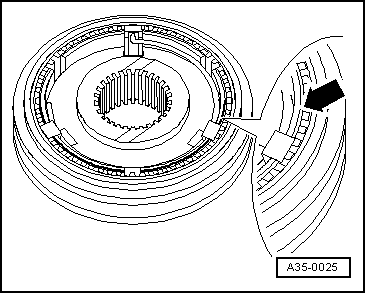

| q | Check for wear → Fig. |

| 4 - | Synchromeshed gear for 5th gear |

| 5 - | Needle bearing |

| q | For 5th gear |

| q | Renew together with → Item |

| 6 - | Sleeve |

| q | For 5th gear needle bearing |

| q | Renew together with → Item |

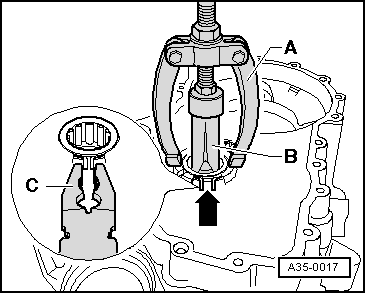

| q | Press off with bearing mounting with deep groove ball bearing → Fig. |

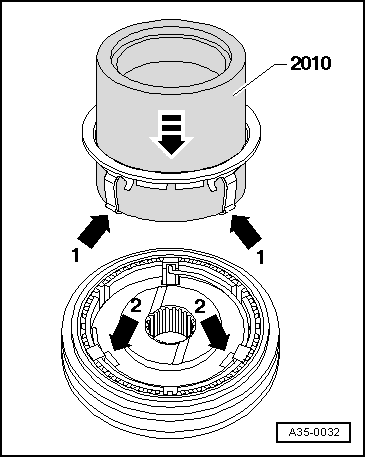

| q | Pressing on → Fig. |

| 7 - | Gearbox housing |

| 8 - | Bearing mounting with deep groove ball bearing |

| q | Renew deep groove ball bearing only together with bearing mounting |

| q | If bearing mounting is separated from gearbox housing, then mounting must always be renewed. |

| q | Pressing off → Fig. |

| q | Pressing on → Anchor |

| 9 - | Input shaft |

| 10 - | Needle bearing |

| q | For 3rd gear |

| 11 - | Synchromeshed gear for 3rd gear |

| 12 - | Synchro-ring for 3rd gear |

| q | Check for wear → Fig. |

| 13 - | Locking collar with synchro-hub for 3rd and 4th gear |

| q | Press off with synchromeshed gear for 3rd gear → Fig. |

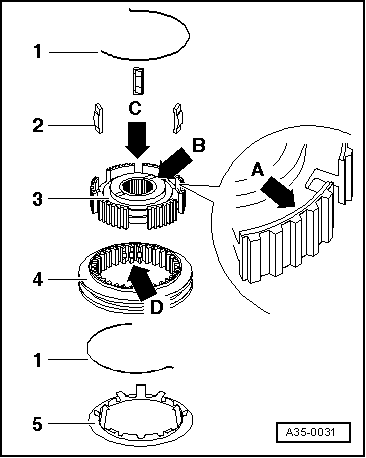

| q | Dismantling → Fig. |

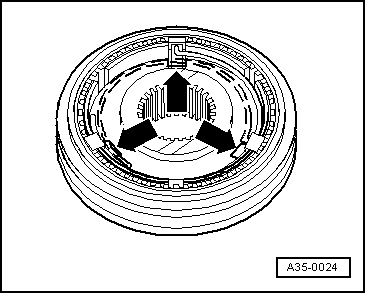

| q | Installation position, locking collar and synchro-hub → Fig. |

| q | Assembling → Fig. |

| q | Pressing on → Fig. |

| 14 - | Synchro-ring for 4th gear |

| q | Check for wear → Fig. |

| 15 - | Synchromeshed gear for 4th gear |

| 16 - | Sleeve |

| q | For 4th gear needle bearing |

| q | Renew together with → Item |

| q | Press off with synchromeshed gear for 3rd gear → Fig. |

| q | Pressing on → Fig. |

| 17 - | Needle bearing |

| q | For 4th gear |

| q | Renew together with → Item |

| 18 - | Thrust washer |

| 19 - | Inner race for cylindrical roller bearing |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 20 - | Retaining ring |

| q | Renew |

| q | Determining thickness → Fig. |

| 21 - | Cylindrical roller bearing |

| q | With retaining ring |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Installation position: retaining ring in bearing faces input shaft |

| 22 - | Clutch housing |

| 23 - | Spring |

| q | Installation position → Fig. |

| 24 - | 3rd and 4th gear locking collar |

| 25 - | 3rd and 4th gear synchro-hub |

| 26 - | Locking pieces (Qty. 3) |

| 27 - | Spring |

| q | Installation position → Fig. |

| 28 - | Locking pieces (Qty. 3) |

| 29 - | Synchro-hub for 5th gear |

| 30 - | Locking collar for 5th gear |

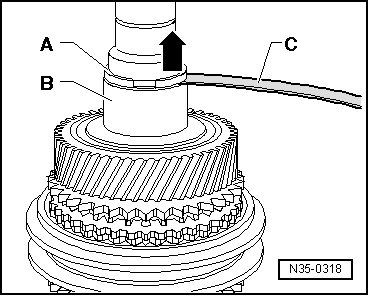

| 31 - | Stop ring |

| q | Prevents locking pieces from drifting out |

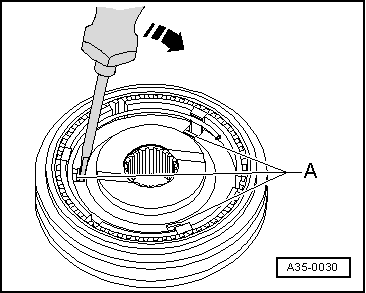

| q | Removing → Fig. |

| q | Installing → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

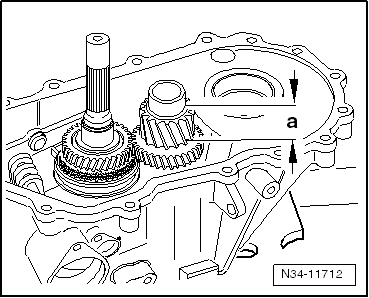

| Gap -a- | Installation dimension | Wear limit |

| 3rd, 4th and 5th gear | 1.1…1.7 mm | 0.5 mm |

|

|

|

|

|

|

Note

Note

|

|

| Measured value (mm) | Retaining ring thickness (mm) | Axial play (mm) |

| 0.05…0.14 | 2.0 | 0.05…0.15 |

| 0.15…0.24 | 2.1 | 0.05…0.15 |

| 0.25…0.34 | 2.2 | 0.05…0.15 |

| 0.35…0.44 | 2.3 | 0.05…0.15 |

| 0.45…0.51 | 2.4 | 0.05…0.10 |

Note

Note |

|

|

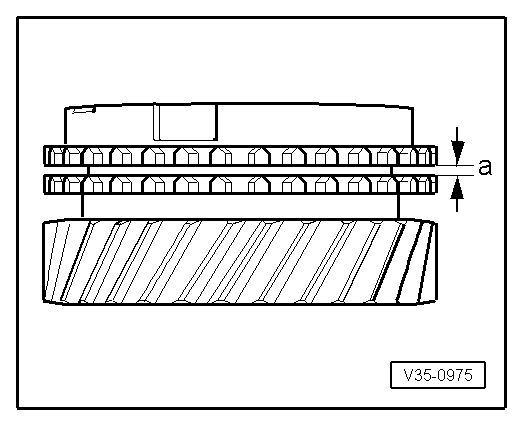

| Dimension -a- = 30.6 mm | |

| Insert shim -T10083/1- → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING