Golf Mk6

| Adjusting differential |

| Special tools and workshop equipment required |

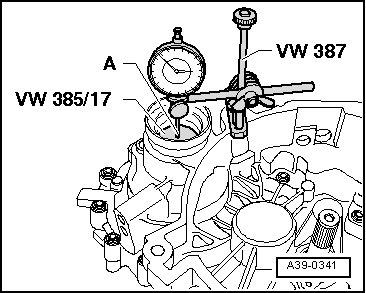

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

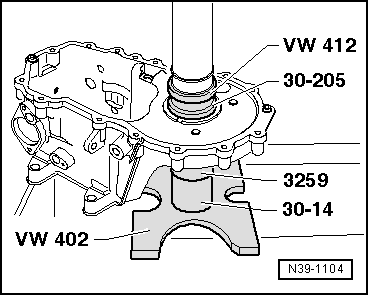

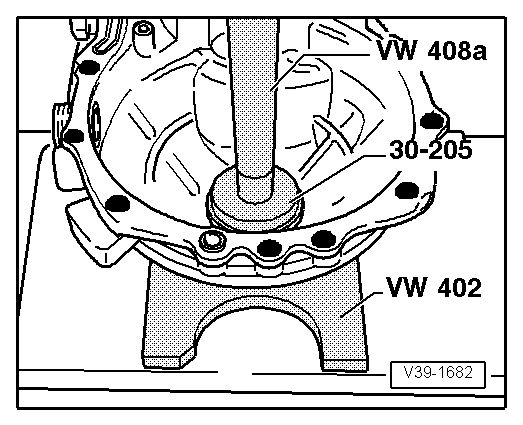

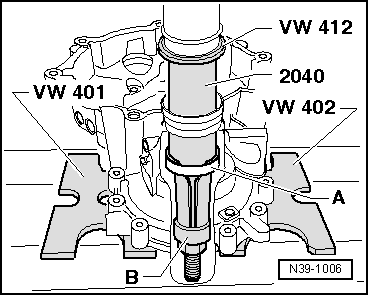

| t | Pressure plate -VW 402- |

| t | Pressure plate -VW 401- |

| t | Press tool -VW 408- |

| t | Press tool -VW 412- |

| t | Thrust plate -30-205- |

| t | Tube -30-14- |

| t | Tube -2040- |

| t | Tube -3259- |

| t | Torque wrench -V.A.G 1331- |

| t | -1-Internal puller -Kukko 21/7- |

| t | Dial gauge |

|

Note

Note

|

|

|

|

|

|

| Measured value | 1.50 mm |

| + Preload (constant) | 0.35 mm |

| Thickness of shim = | 1.85 mm |

|

|