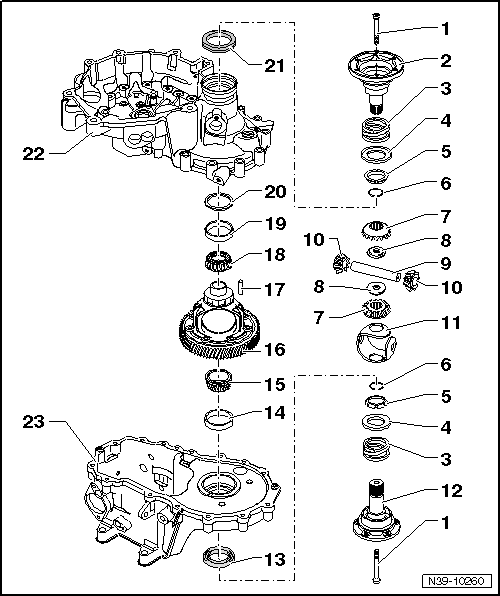

Golf Mk6

| Assembly overview - differential |

| 1 - | Countersunk bolt, 25 Nm |

| q | Screw in together with threaded piece |

| 2 - | Right flange shaft |

| 3 - | Compression spring for flange shaft |

| q | Installed behind flange shafts |

| 4 - | Thrust washer |

| q | Installation position: shoulder towards spring |

| 5 - | Tapered ring |

| q | Installation position: taper towards differential cage |

| 6 - | Retaining ring |

| q | Holds tapered ring, thrust washer and spring in position when flange shaft is removed |

| 7 - | Large differential bevel gear |

| q | Installing → Fig. |

| 8 - | Threaded piece |

| q | Installing → Fig. |

| 9 - | Differential pinion pin |

| q | To remove, shear off spring pin → Fig. |

| q | Installing → Fig. |

| 10 - | Small differential bevel gear |

| q | Installing → Fig. |

| 11 - | One-piece thrust washer |

| q | Coat with gear oil when installing |

| 12 - | Left flange shaft |

| 13 - | Oil seal for left flange shaft |

| q | Renewing with manual gearbox installed → Chapter. |

| 14 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 15 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 16 - | Differential cage |

| q | With final drive gear |

| 17 - | Spring pin |

| q | For securing differential pinion pin |

| q | Will be sheared off when removed → Fig. |

| 18 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 19 - | Tapered roller bearing outer race |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 20 - | Shim |

| q | For differential |

| q | Determining thickness → Chapter |

| 21 - | Oil seal for right flange shaft |

| q | Renewing with manual gearbox installed → Chapter. |

| 22 - | Clutch housing |

| q | Repairing → Chapter. |

| 23 - | Gearbox housing |

| q | Repairing → Chapter. |