Golf Mk6

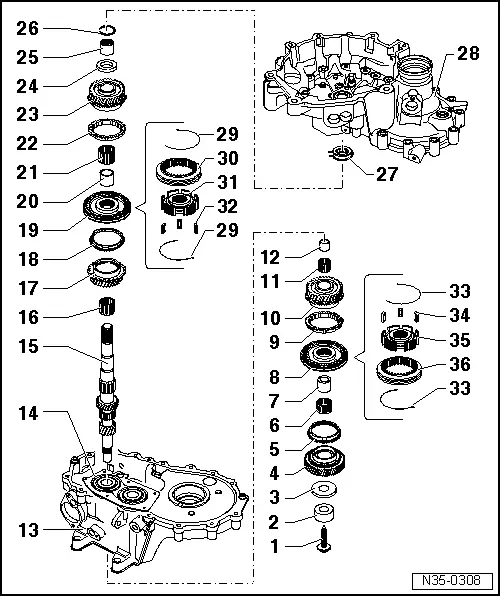

| Assembly overview - input shaft |

Note

Note| t | When installing new gears or new input shaft, refer to → Electronic parts catalogue „ETKA“ and technical data. |

| t | Install all bearings, synchromeshed gears and synchro-rings on input shaft with gear oil. |

| t | Do not interchange synchro-rings. When reusing always fit to the original gear. |

| 1 - | Bolt |

| q | Removing and installing → Chapter |

| 2 - | Cylindrical roller bearing inner race |

| q | Combined with thrust washer → Chapter |

| q | Mark before removing |

| q | Do not interchange with inner race for cylindrical roller bearing of output shaft |

| q | Removing and installing → Chapter |

| 3 - | Thrust washer |

| q | Combined with inner race of cylindrical roller bearing → Chapter |

| 4 - | Synchromeshed gear for 6th gear |

| 5 - | Synchro-ring for 6th gear |

| q | Check for wear → Fig. |

| 6 - | Needle bearing |

| q | For 6th gear |

| q | Replace together with sleeve. |

| q | Two-part → Chapter |

| 7 - | Sleeve |

| q | For 6th gear needle bearing. |

| q | Renew together with needle bearing. |

| q | Removing and installing → Chapter |

| 8 - | Locking collar with synchro-hub for 5th and 6th gears |

| q | Removing and installing → Chapter |

| q | Dismantling → Fig. |

| q | Assembling locking collar and synchro-hub for 5th and 6th gears → Fig. and → Fig. |

| q | Installation position → Fig. |

| 9 - | Synchro-ring for 5th gear |

| q | Will be damaged during removal of input shaft |

| q | Always renew |

| q | Check for wear → Fig. |

| 10 - | Synchromeshed gear for 5th gear |

| 11 - | Needle bearing |

| q | For 5th gear |

| q | Renew together with |

| 12 - | Sleeve |

| q | For 5th gear needle bearing |

| q | Renew together with |

| q | Press off with bearing mounting with deep groove ball bearing |

| q | Pressing on → Fig. |

| 13 - | Gearbox housing |

| q | Repairing → Chapter. |

| 14 - | Bearing mounting with deep groove ball bearing |

| q | Renew deep groove ball bearing only together with bearing mounting |

| q | If bearing mounting is separated from gearbox housing, then mounting must always be renewed. |

| q | Gearbox for 1.6 l engine: press off without gear wheel for 5th gear → Fig. |

| q | Gearbox for 1.4 l engine: press off with gear wheel for 5th gear → Fig. |

| q | Pressing on → Fig. |

| 15 - | Input shaft |

| q | Clean residual locking fluid from threaded hole in input shaft using a thread chaser. |

| 16 - | Needle bearing |

| q | For 3rd gear |

| 17 - | Synchromeshed gear for 3rd gear |

| 18 - | Synchro-ring for 3rd gear |

| q | Check for wear → Fig. |

| 19 - | Locking collar with synchro-hub for 3rd and 4th gear |

| q | Press off with synchromeshed gear for 3rd gear → Fig.. |

| q | Dismantling → Fig. |

| q | Installation position, locking collar and synchro-hub → Fig. |

| q | Assembling → Fig. |

| q | Pressing on → Fig. |

| 20 - | Sleeve |

| q | For 4th gear needle bearing |

| q | Renew together with |

| q | Press off with synchromeshed gear for 3rd gear → Fig.. |

| q | Pressing on → Fig. |

| 21 - | Needle bearing |

| q | For 4th gear |

| q | Renew together with |

| 22 - | Synchro-ring for 4th gear |

| q | Check for wear → Fig. |

| 23 - | Synchromeshed gear for 4th gear |

| 24 - | Thrust washer |

| 25 - | Cylindrical roller bearing inner race |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 26 - | Retaining ring |

| q | Renew |

| q | Determining thickness → Fig. |

| 27 - | Cylindrical roller bearing |

| q | With retaining ring |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Installation position: retaining ring in bearing faces input shaft |

| 28 - | Clutch housing |

| q | Repairing → Chapter. |

| 29 - | Spring |

| q | Installation position → Fig. |

| 30 - | 3rd and 4th gear locking collar |

| 31 - | 3rd and 4th gear synchro-hub |

| 32 - | Locking pieces (Qty. 3) |

| 33 - | Spring |

| q | Installation position → Fig. |

| 34 - | Locking pieces (Qty. 3) |

| 35 - | Synchro-hub for 5th and 6th gears |

| 36 - | Locking collar for 5th and 6th gears |