| t

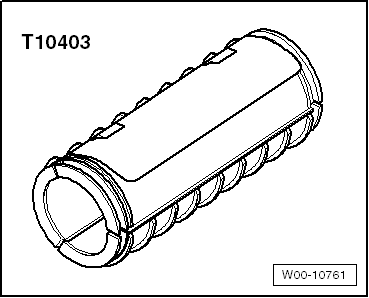

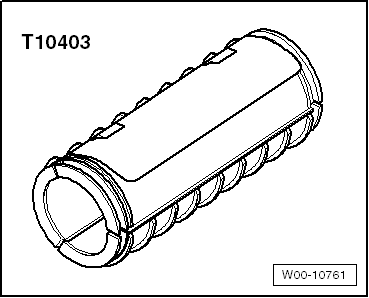

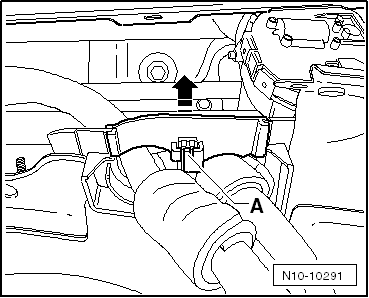

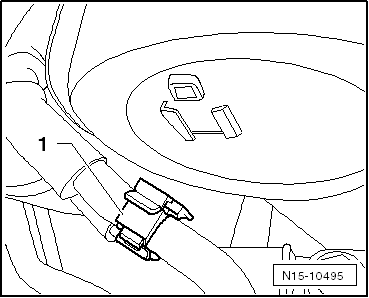

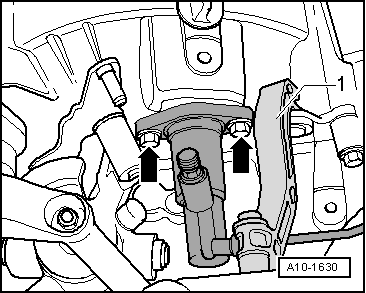

| Transportation lock -T10403- |

| t

| Engine bung set -VAS 6122- (not shown) |

Note | t

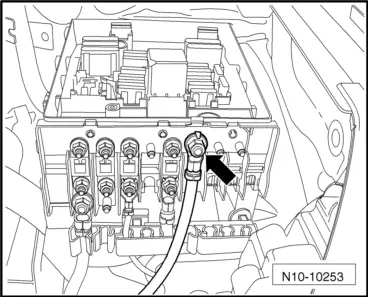

| Before carrying out further work, disconnect battery earth strap. Check whether a coded radio is fitted. Obtain anti-theft coding if necessary. |

| t

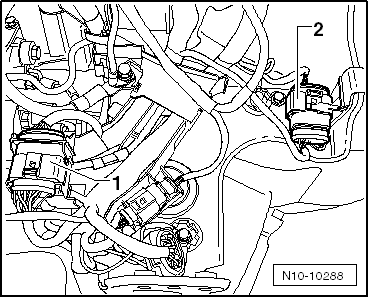

| The engine is removed forwards together with the gearbox. |

| t

| All cable ties that are opened or cut through when the engine is removed must be renewed in the same position when the engine is installed. |

WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

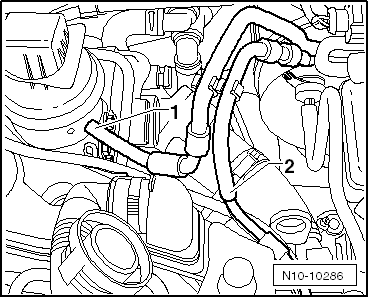

| Route all the various lines and electrical wiring so that they are in their original positions. |

| t

| e.g. for fuel, hydraulics, activated charcoal filter system, coolant and refrigerant, brake fluid, vacuum. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

| »Carry out the following work sequence« |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING