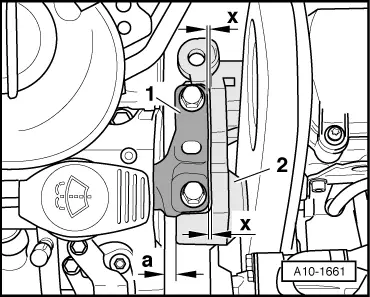

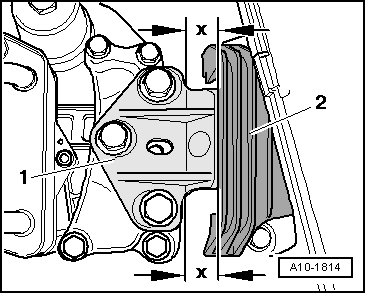

| Adjusting power unit mounting, Golf and Scirocco |

WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route lines of any kind so that the original routing can be restored. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

| –

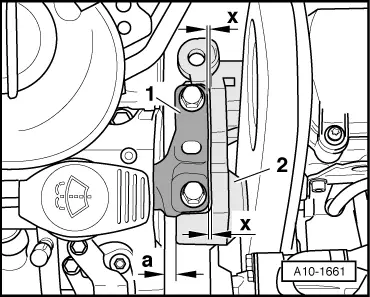

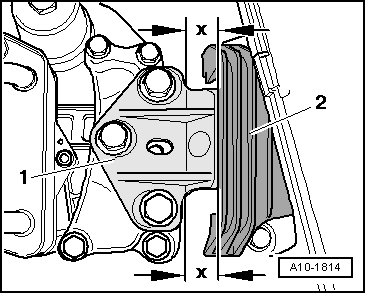

| Bracing the engine in its installation position → Chapter. |

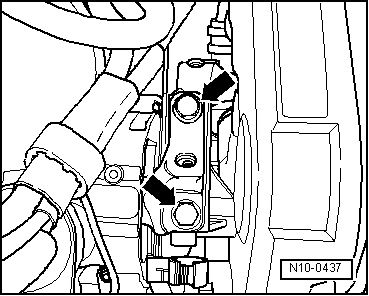

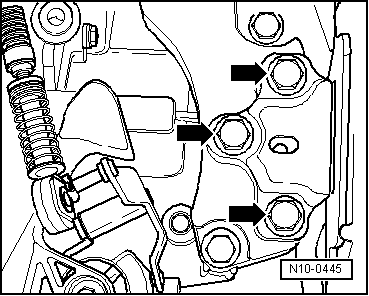

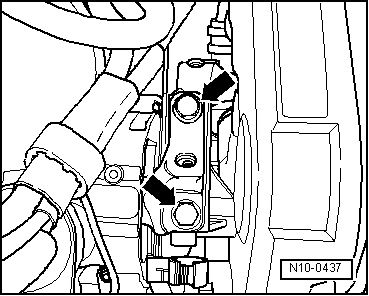

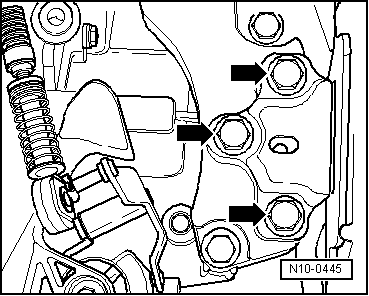

Note | The securing bolts for the assembly mountings may only be removed if the engine is supported with support bracket -10-222 A-! |

|

|

|

Note

Note

Note

Note