Note | t

| Read anti-theft radio code as the next work step requires the earth strap of the battery to be disconnected. |

| t

| All cable ties which are opened or cut through when cylinder head is removed must be renewed/replaced in the same position when the cylinder head is installed. |

WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route lines of any kind so that the original routing can be restored. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

| –

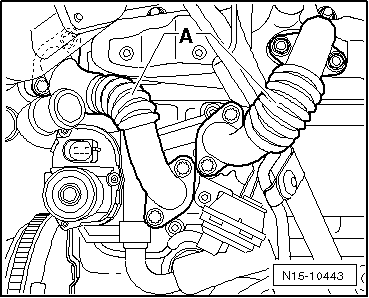

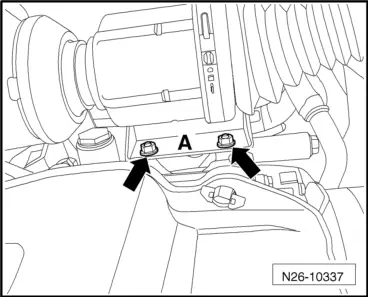

| Remove cowling together with radiator fan -V7- and radiator fan on right of radiator -V35- → Chapter. |

| –

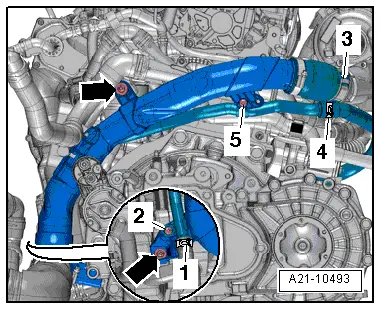

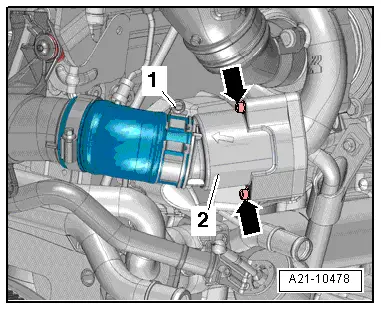

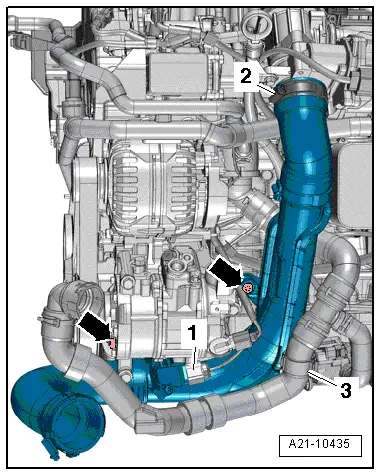

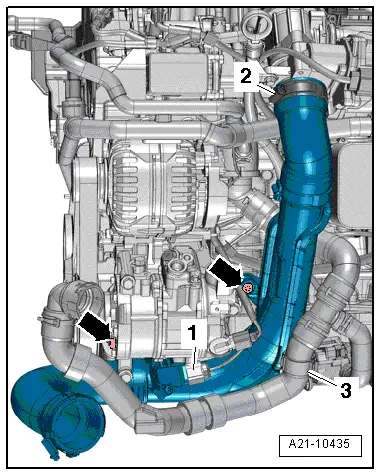

| Remove connecting hose on »cold side« → Item of charge air cooler. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING Caution

Caution