Golf Mk6

| Vehicles with »new« seal |

| Special tools and workshop equipment required |

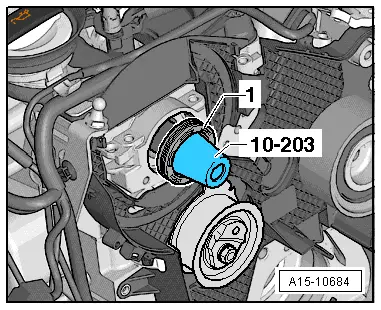

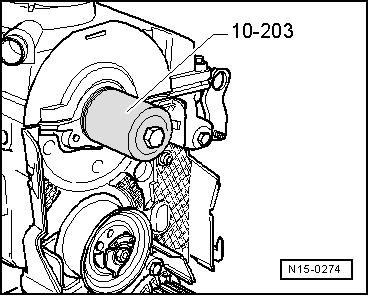

| t | Fitting tool -V.A.G 10-203- |

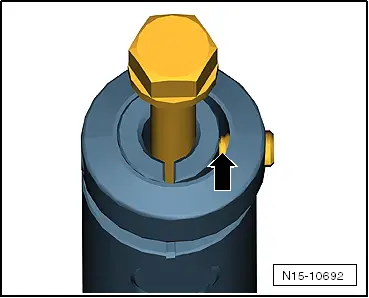

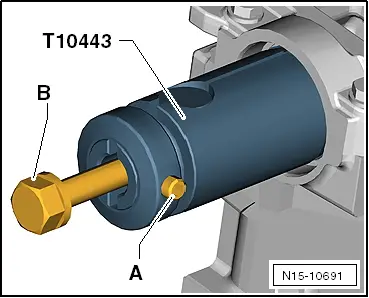

| t | Oil seal extractor -T10443- |

| t | Torque wrench -V.A.G 1331/- |

| t | Torque wrench -V.A.G 1332/- |

| t | Bolt M12 x 1.5 x 75 |

Note

Note |

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution