| –

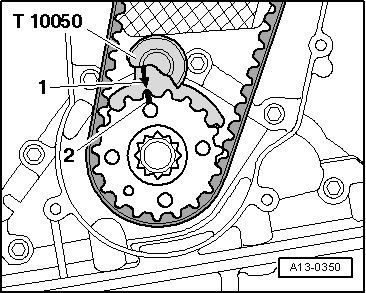

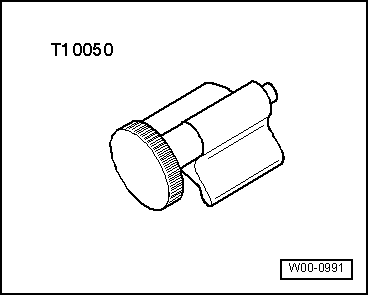

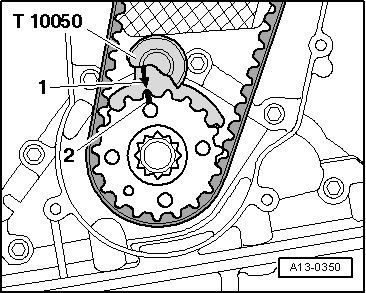

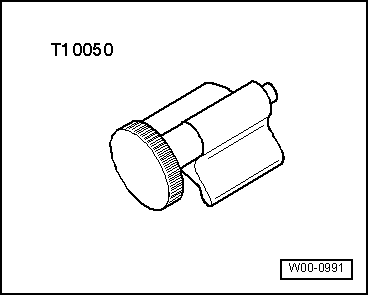

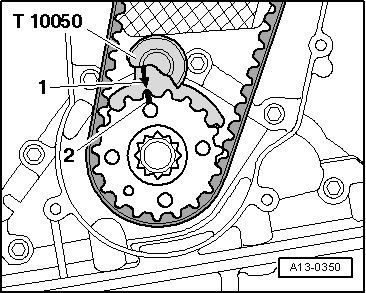

| Lock crankshaft in position with crankshaft stop -T10050-. |

| l

| The markings on the toothed belt sprocket -2- and the crankshaft stop -1- must align -arrow-. When doing this, the pin of the crankshaft stop must engage in the drilling of sealing flange. |

Note | Crankshaft stop can only be pushed onto toothed belt sprocket from face end of splines. |

| –

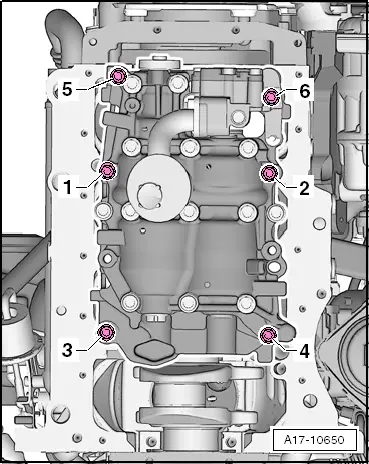

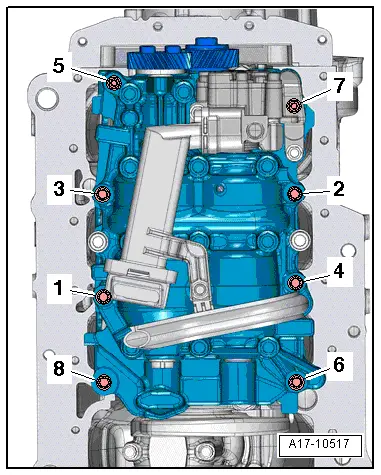

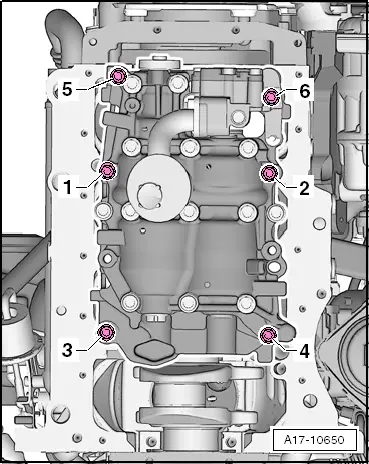

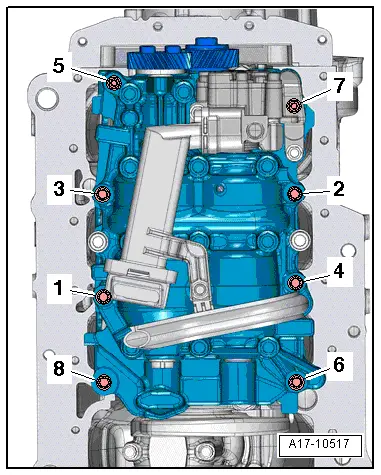

| Unscrew bolts in the sequence -8 … 1- or -6 ... 1- and remove balancer shaft module together with oil pump. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note