| –

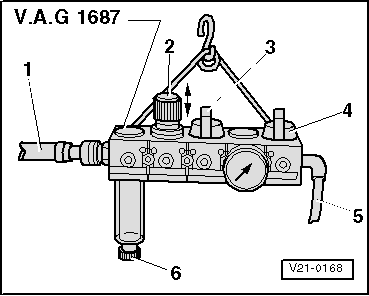

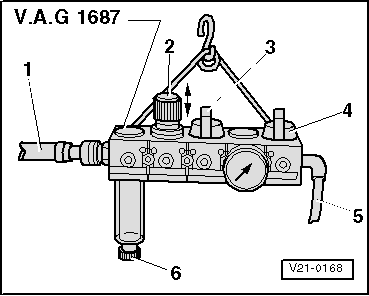

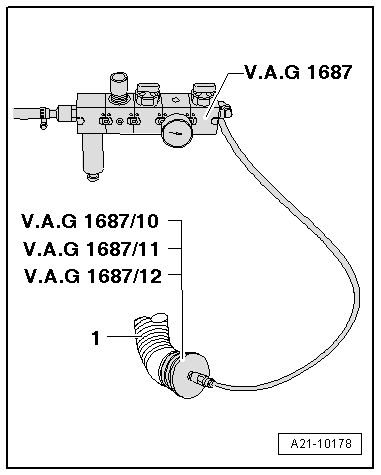

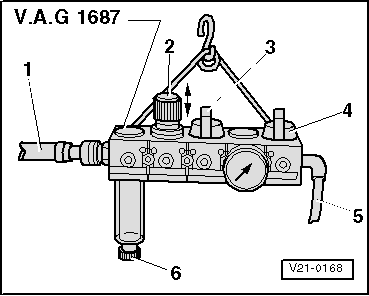

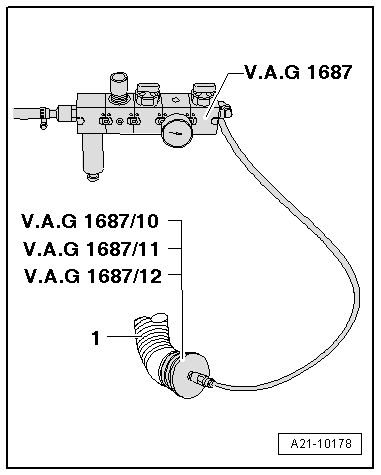

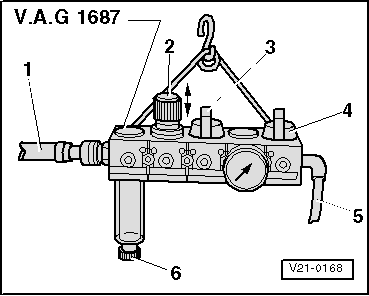

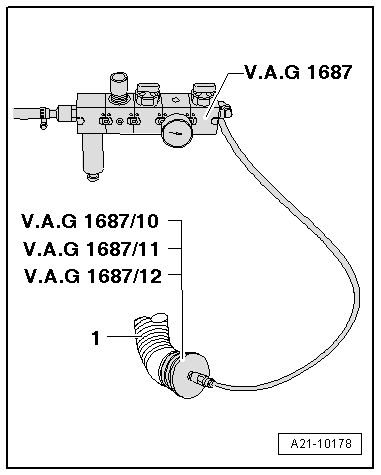

| Connect compressed air hose -1- (compressed air supply) to charge air system tester -V.A.G 1687-. |

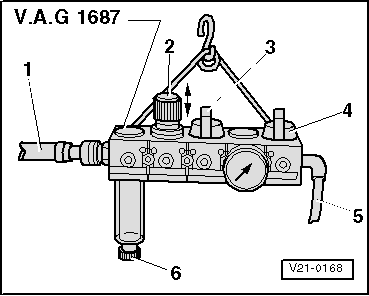

Note | If there is water in inspection glass, drain via drain screw -6-. |

| –

| Set pressure to 0.5 bar at pressure control valve -2-. |

Caution | The pressure must not exceed 0.5 bar! If the pressure is too high this can cause damage to the engine. |

|

| –

| Open valve -4- and wait until test circuit is full. If necessary, regulate pressure to 0.5 bar. |

| –

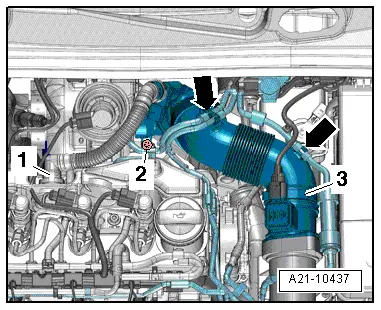

| Check charge-air system for leaks by: |

| t

| using standard leak detecting spray |

| t

| Ultrasonic tester -V.A.G 1842- |

Note | t

| Slight leaks on the intake side of turbocharger are permissible, as the intake hoses are not designed for high-pressure. |

| t

| A small amount of air escapes through the valves and enters the engine. Therefore a holding pressure test is not possible. |

| t

| If a leak has been located, observe notes for charge air system when carrying out any repair work. |

| t

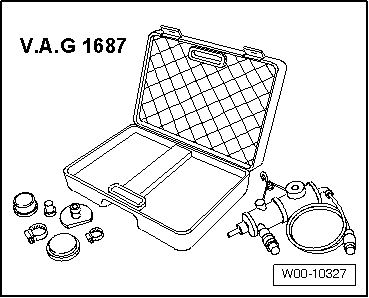

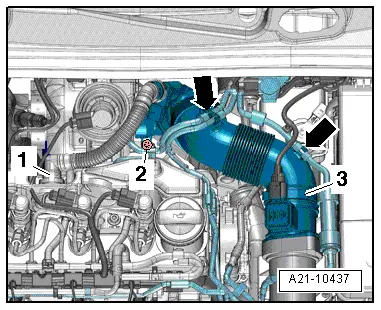

| Depressurise test circuit by detaching coupling from adapter -1687/10- before removing adapter. |

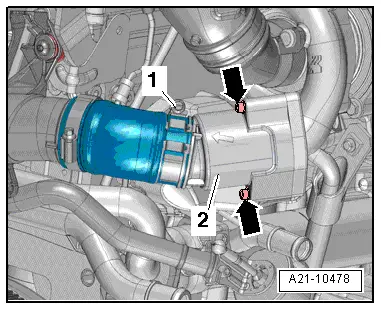

| Installation is carried out in the reverse order; note the following: |

Note | t

| Renew the seal and O-ring. |

| t

| Hose connections and air intake pipes/hoses must be free of oil and grease when installing. |

| –

| Installing inlet connection and pulsation damper → Chapter. |

| –

| Installing intake hoses with screw-type clips → Chapter. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note Note

Note