Golf Mk6

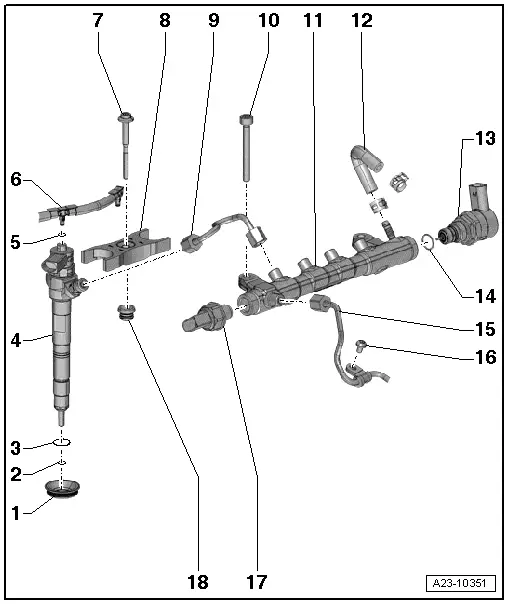

| Assembly overview - injectors |

Caution

Caution

|

| 1 - | Seal |

| q | In cylinder head cover. |

| q | Removing and installing → Chapter. |

| 2 - | Copper washer |

| q | Renew. |

| 3 - | O-ring |

| q | Renew. |

| 4 - | Injector |

| q | When removing and installing, always renew the following components and seals/O-rings: „copper seal“, „O-ring for injector bore“, „O-ring for injector return connection“. |

| q | The following components and seals/O-rings must always be renewed when an injector is renewed: „clamping piece“, „copper seal“, „O-ring for injector shaft“ and „O-ring for injector return connection“. |

| q | Before re-using „high-pressure injection line“, inspect taper seats visually for damage such as transverse scores or corrosion; always renew if damaged. |

| q | If they are to be reinstalled, the injectors, high-pressure lines and clamping pieces must only ever be refitted on the same cylinder. |

| q | Removing and installing → Chapter. |

| 5 - | O-ring |

| q | Renew. |

| 6 - | Fuel return line |

| q | To fuel tank. |

| q | Must not be kinked, damaged or blocked. |

| q | Do not dismantle. |

| q | After exchanging, engine must be run at idling speed for approx. 2 minutes to bleed fuel system. Then check fuel return lines for leaks. |

| 7 - | 8 Nm + turn 180° further. |

| q | Renew. |

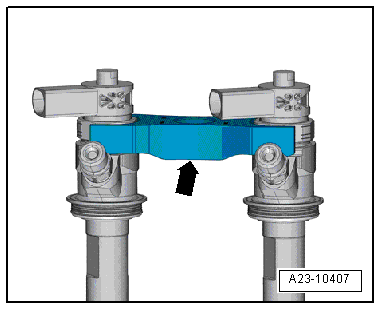

| 8 - | Clamping piece |

| q | If they are to be reinstalled, the injectors and clamping pieces must only ever be refitted on the same cylinder. |

| q | When an injector is renewed, the clamping piece must be renewed at the same time. |

| q | Installation position → Fig.. |

| 9 - | High-pressure line, 28 Nm |

| q | Between fuel rail and injectors. |

Note

Note| t | Observe cylinder specific markings when reusing high-pressure lines. |

| t | The high-pressure lines may be re-used after the following checks: |

| t | Check taper seat of respective high-pressure line for deformation and cracks. |

| t | The line hole must not be deformed, constricted or damaged. |

| t | Corroded lines should no longer be used. |

| q | Install so that component is not under tension. |

| 10 - | 22 Nm |

| 11 - | Fuel rail |

| q | Removing and installing → Chapter. |

| 12 - | Fuel return hose |

| 13 - | Fuel pressure regulating valve -N276-, 80 Nm. |

| q | Always renew after removing |

| q | Removing and installing → Chapter. |

| 14 - | O-ring |

| q | Renew. |

| 15 - | High-pressure line, 28 Nm |

| q | Between high-pressure pump and fuel rail |

Note

Note| t | Observe cylinder specific markings when reusing high-pressure lines. |

| t | The high-pressure lines may be re-used after the following checks: |

| t | Check taper seat of respective high-pressure line for deformation and cracks. |

| t | The line hole must not be deformed, constricted or damaged. |

| t | Corroded lines should no longer be used. |

| 16 - | 8 Nm |

| q |

| 17 - | Fuel pressure sender -G247-, 100 Nm |

| q | Always renew after removing |

| q | Removing and installing → Chapter. |

| 18 - | Grommet |

| q | In cylinder head cover. |

|

|