Golf Mk6

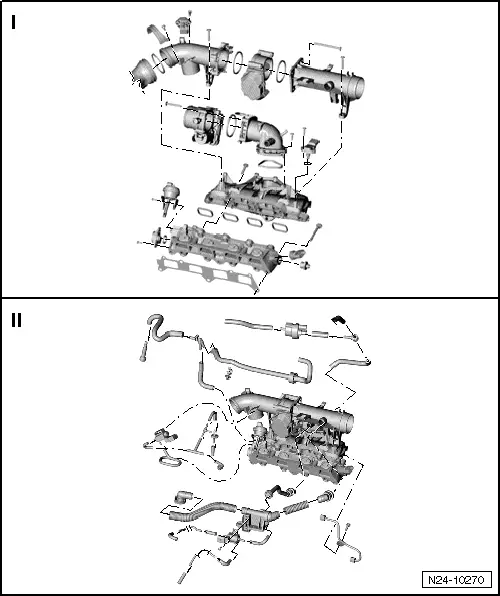

| Assembly overview - intake manifold |

Note

Note

|

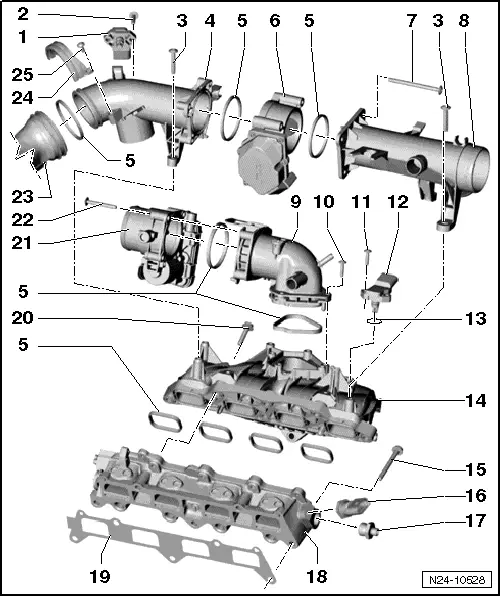

| 1 - | Intake air temperature sender 3 -G520- with intake manifold pressure sender 3 -G583- |

| 2 - | 5 Nm |

| 3 - | 7 Nm |

| q | Self-tapping bolt. |

| q | The securing bolt may only be tightened using a power-operated screwdriver if the screwdriver speed is max. 500 rpm and a max. tightening torque of 7 Nm is set. |

| 4 - | Intake connecting pipe |

| 5 - | Seal |

| q | Renew. |

| q | Before installing, lightly coat seal with clean engine oil. |

| 6 - | Regulating flap control unit -J808- |

| q | Removing and installing → Chapter |

Note

Note| Regulating flap control units with plastic housing need not be adapted to the engine control unit -J623-. |

| q | If renewed, erase learnt values and adapt engine control unit -J623- → Vehicle diagnostic tester„Guided functions“. |

| 7 - | 7 Nm |

| q | Self-tapping bolt. |

| q | The securing bolt may only be tightened using a power-operated screwdriver if the screwdriver speed is max. 500 rpm and a max. tightening torque of 7 Nm is set. |

| 8 - | Intake connecting pipe |

| 9 - | Intake manifold connection |

| 10 - | 7 Nm |

| q | Self-tapping bolt. |

| q | The securing bolt may only be tightened using a power-operated screwdriver if the screwdriver speed is max. 500 rpm and a max. tightening torque of 7 Nm is set. |

| 11 - | 5 Nm |

| 12 - | Intake manifold pressure sender -G71- |

| 13 - | O-ring |

| q | Renew. |

| 14 - | Intake manifold |

Note

Note| t | If the intake manifold was removed, you must check that all hoses are securely connected on the intake manifold after installation. |

| t | Pull hoses with fastener to make sure they are securely connected. |

| q | To remove: removing and installing regulating flap control unit -J808- and throttle valve module -J338- → Chapter. |

| 15 - | 20 Nm |

| 16 - | Fuel pressure sender -G247-, 22 Nm |

| q | Checking fuel pressure in high-pressure section → Chapter. |

| 17 - | 80 Nm |

| 18 - | Intake manifold lower part |

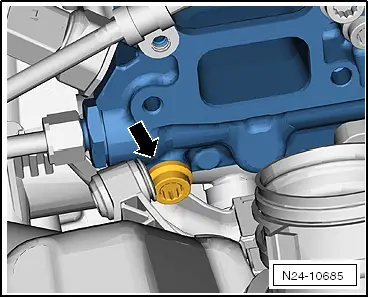

| q | To remove and install: using "bracket for bits 5/16""" -V.A.G 1766/2- and Bit -3320/2- → Fig. |

| q | To remove, removing and installing regulating flap control unit -J808-, throttle valve module -J338- and intake manifold → Chapter. |

| 19 - | Seal |

| q | Renew. |

| q | Note installation position. |

| 20 - | 20 Nm |

| 21 - | Throttle valve module -J338- |

| q | Removing and installing → Chapter |

| q | Clean → Chapter. |

| q | If renewed, erase learnt values and adapt engine control unit -J623- → Vehicle diagnostic tester„Guided functions“. |

| 22 - | 7 Nm |

| 23 - | Pressure pipe |

| q | From turbocharger |

| 24 - | Retaining clip |

| 25 - | 7 Nm |

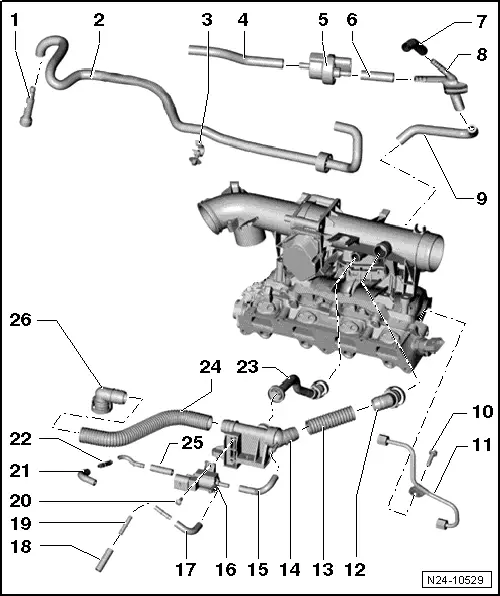

| 1 - | Connection |

| q | For fuel supply. |

| 2 - | Fuel hose |

| q | For fuel supply. |

| q | Low-pressure. |

| q | To high-pressure pump. |

| 3 - | Retaining clamp |

| 4 - | Connecting hose |

| q | To activated charcoal filter solenoid valve 1 -N80- |

| 5 - | Activated charcoal filter solenoid valve 1 -N80- |

| 6 - | Connecting hose |

| 7 - | To pressure pipe. |

| 8 - | Connecting pipe |

| 9 - | Connecting hose |

| q | To intake manifold connection. |

| 10 - | 8 Nm |

| 11 - | Fuel pipe |

| q | High-pressure. |

| q | Specified torque for union nuts: 18 Nm. |

| 12 - | Connection |

| q | To intake connecting pipe. |

| 13 - | Connecting hose |

| 14 - | Non-return valve |

| q | For crankcase ventilation. |

| q | Specified torque: 10 Nm |

| 15 - | Connecting hose |

| 16 - | Charge pressure control solenoid valve -N75- |

| 17 - | Connecting hose |

| 18 - | Connecting hose |

| q | To turbocharger. |

| 19 - | Connection |

| 20 - | 5 Nm |

| 21 - | Connecting hose |

| q | To turbocharger. |

| 22 - | Connection |

| 23 - | Connection |

| q | For crankcase ventilation. |

| 24 - | Connecting hose |

| q | For crankcase ventilation. |

| 25 - | Connecting hose |

| q | To charge pressure control solenoid valve -N75-. |

| 26 - | Connection |

| q | For crankcase ventilation. |

| q | Connected to valve timing housing. |

| q | Specified torque: 10 Nm |