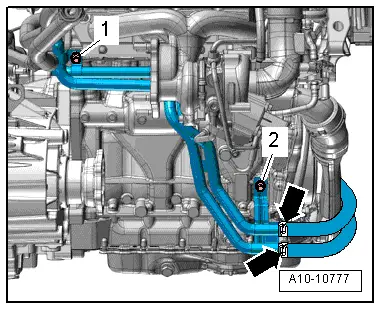

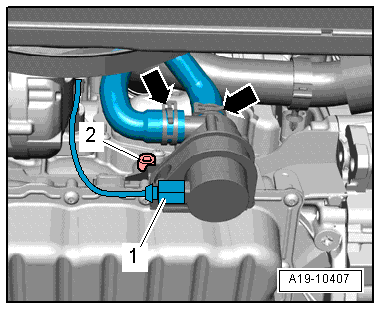

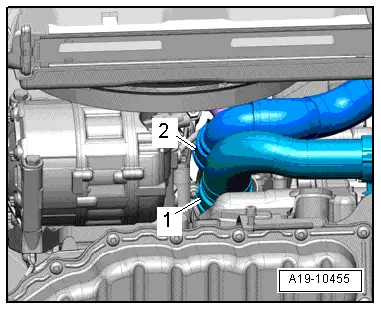

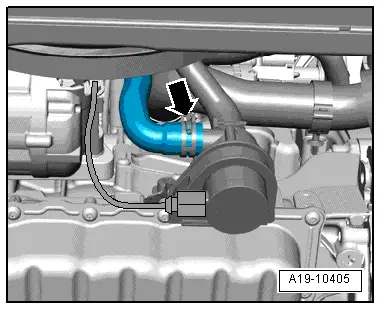

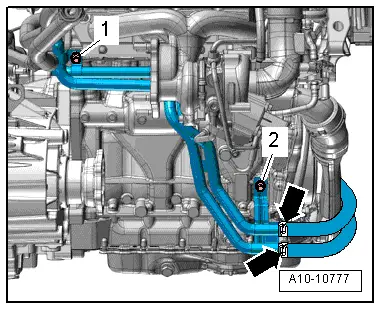

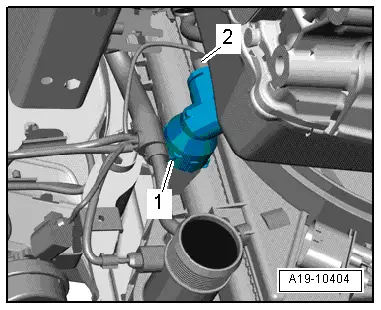

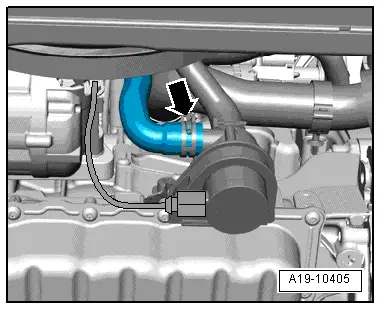

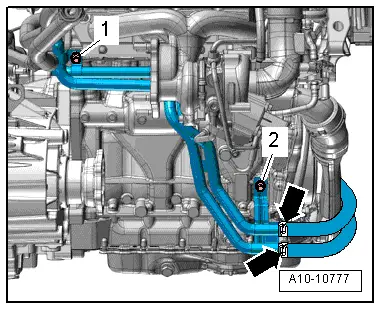

| Vehicles with auxiliary heater: |

| –

| Disconnect coolant hoses -arrows- and drain off remaining coolant. |

Caution | Only distilled water may be used for mixing with coolant additives. The use of distilled water ensures optimum protection against corrosion. |

|

Note | t

| The effectiveness of a coolant is largely dependent on the water used for mixing. Because the different substances that are mixed with the water can be specific to individual countries or even regions, Volkswagen has decided to define the water quality for cooling systems. Distilled water meets all the requirements. It is therefore recommended that distilled water be mixed with the coolant whenever an older model's coolant is replenished or replaced. The use of distilled water is obligatory for new types of vehicle (year of manufacture 2010 ►). |

| t

| Use only coolant additives in accordance with the → Electronic parts catalogue (ETKA). Other coolant additives may reduce corrosion protection substantially. The resulting damage could lead to loss of coolant and subsequent severe damage to the engine. |

| t

| The correct coolant solution ratio helps prevent damage from freezing and corrosion as well as scaling. Moreover, the boiling temperature is raised. Therefore, the cooling system must be filled all year round with coolant additive. |

| t

| Because of its higher boiling point, the coolant improves engine reliability under heavy loads, particularly in countries with tropical climates. |

| t

| Frost protection must be guaranteed down to about -25 °C (in countries with Arctic climates: down to about -35 °C). |

| t

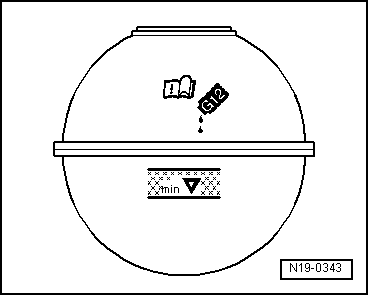

| The coolant concentration must not be reduced by adding water even in warmer seasons and in warmer countries. The coolant additive concentration must be at least 40 %. |

| t

| If a stronger anti-freeze mixture is necessary due to harsher weather conditions, the coolant additive content can be increased. However, this is only permitted to 60% (antifreeze protection to about -40°C). Otherwise, the antifreeze protection will be reduced again and the cooling effect will be impaired. |

| t

| If radiator, heat exchanger, cylinder head or cylinder head gasket is renewed, do not reuse old coolant. |

| t

| The Refractometer -T10007A- is recommended for determining the current anti-freeze density. |

| Recommended mixture ratios: |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution