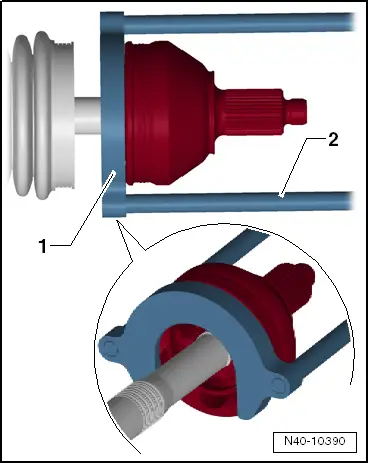

| Tighten clamp on outer joint |

| –

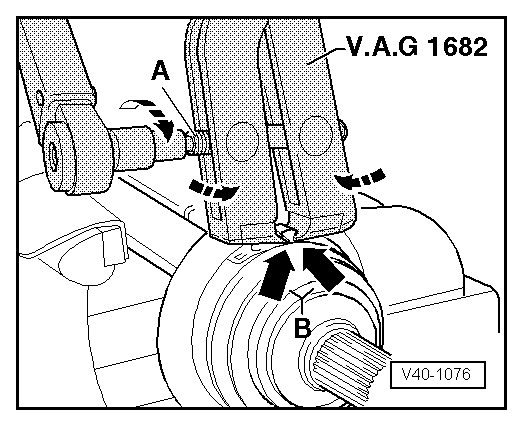

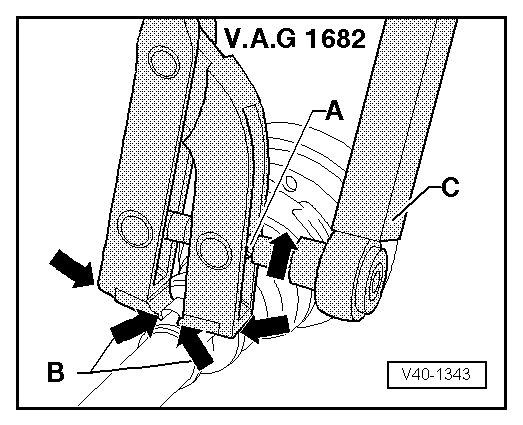

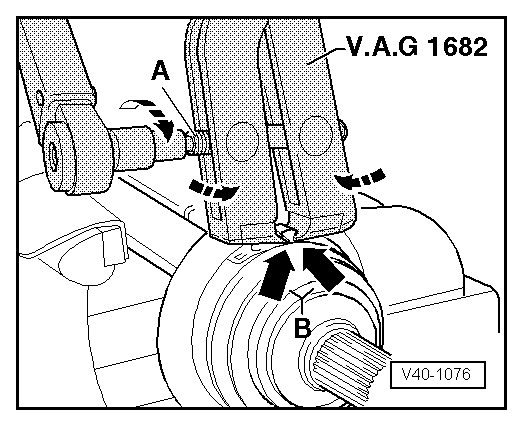

| Apply special pliers-V.A.G 1682- as shown in diagram. Ensure jaws of tool contact corners -arrows B- of clamp. |

| –

| Tighten clamp by turning spindle with a torque wrench (do not cant pliers). |

Note | t

| Because a stainless steel boot clamp is required due to the hard material of the joint boot (compared to rubber), it is possible to tighten the clamp only with clamp tensioner -V.A.G 1682-. |

| t

| Use torque wrench -C- with adjustment range 5 … 50 Nm, (e.g. torque wrench -V.A.G 1331-). |

| t

| Make sure thread of spindle -A- on pliers moves freely. Lubricate with MoS2 grease if necessary. |

| t

| If the thread is tight (e.g. due to dirt), the required clamping force for the boot clamp will not be attained although the correct torque is applied. |

|

|

|

Note

Note

Note

Note