Golf Mk6

| Removing and installing swivel joint |

| Special tools and workshop equipment required |

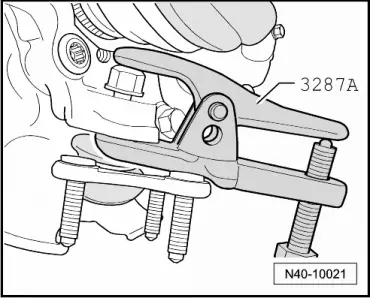

| t | Ball joint puller -3287A- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Angle wrench -V.A.G 1756- |

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

| Specified torques |

| Component | Specified torque | ||

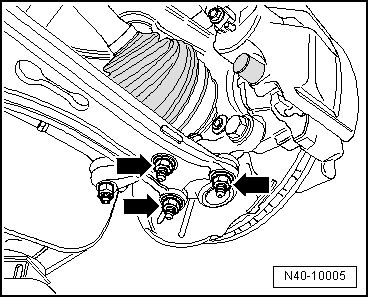

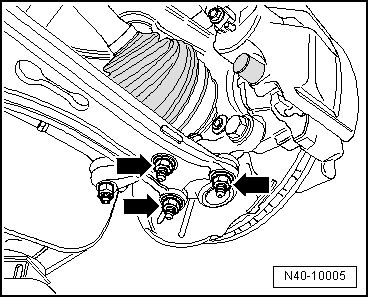

Swivel joint to cast steel suspension link

| 60 Nm | ||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||

Swivel joint to wheel bearing housing

| 60 Nm | ||

Drive shaft to hub

| 70 Nm + 90° |

Caution

Caution