-

‒ →

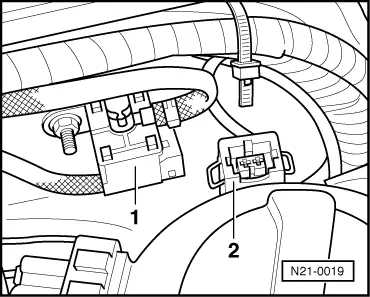

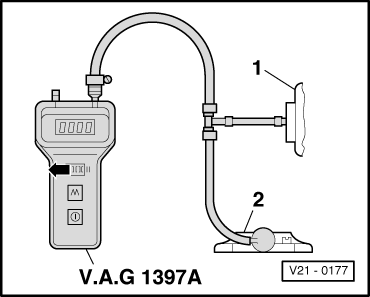

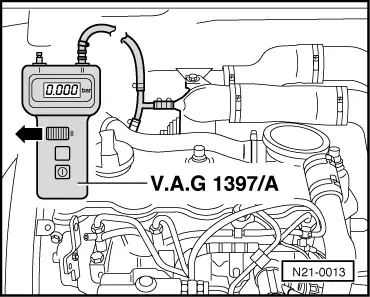

Pull off connecting hose running between intake manifold and diesel direct injection system control unit (J248) and using T-piece connect in turbocharger tester V.A.G 1397 A.

-

‒ Select measuring range ll.

Notes:

-

◆ To operate turbocharger tester see operating instructions.

-

◆ The hoses must be connected so that there is no possibility of leaks.

-

◆ If boost pressure is measured whilst driving, it is necessary for safety reasons, for a second person to operate the turbocharger tester.

-

◆ Ensure that the pressure hose is not trapped between the bonnet and the body.

-

‒ Measure charge pressure at full throttle:

On a rolling road:

In 3rd gear or selector lever position 2 at

3500...4000 rpm.

Whilst driving:

In 2nd gear or selector lever position 1

at full throttle acceleration whilst observing

rev counter.

Note:

The brake pedal must not be operated whilst taking measurements. The control unit thus reduces the fuel quantity which leads to incorrect measurements.

-

‒ Press the memory button "M" on turbocharger tester at 3500...4000 rpm and read off values.

Specification: (Relative pressure)

0.50...0.65 bar

If the charge pressure is not attained:

-

‒ Check charge pressure control valve pressure unit and renew if necessary.

-

‒ Repeat charge pressure check.

If the charge pressure has still not been attained:

If the charge pressure is exceeded:

-

‒ Test charge pressure control solenoid valve (N75). (Through-flow in hose from turbocharger via valve to pressure unit when connector is pulled off).

-

‒ Check pressure unit for charge pressure regulating valve is securely mounted on turbocharger.

-

‒ Check charge pressure control valve pressure unit as well as the operating rod and renew if necessary.

-

‒ Check shaft mounting for charge pressure regulating valve in turbocharger for ease of movement.

When corroded together, renew turbocharger.

Engine code AAZ

Turbocharger and wastegate constitute one unit. A defective turbocharger becomes an item for exchange, as repairs with workshop equipment are not possible.

Prerequisites for the perfect functioning of the turbocharger and attainment of prescribed boost pressure are:

-

● No leaks on intake and exhaust systems.

-

● Control pipe to charge pressure regulating valve is not blocked, loose or leaking.

-

● No faults in engine and fuel injection system, e.g. commencement of injection, maximum speed, injectors and compression pressure.

Test sequence

-

‒ The charge pressure is measured under full load, whilst driving or on a rolling road. Test duration per measurement max. 10 seconds.

|