Passat (B3)

|

|

|

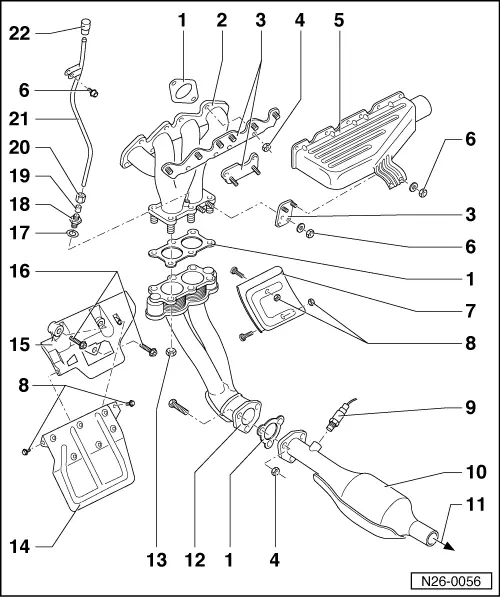

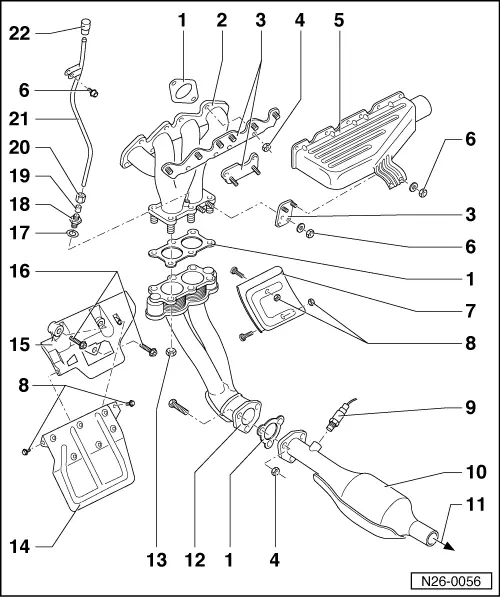

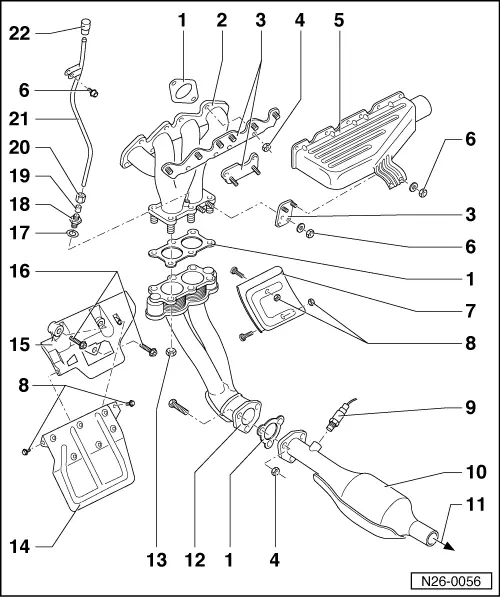

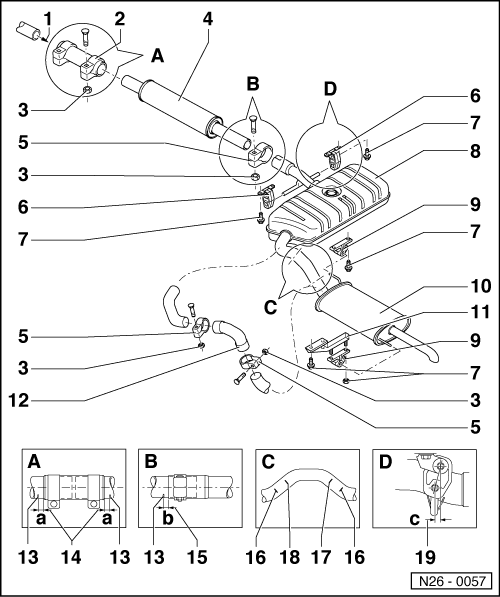

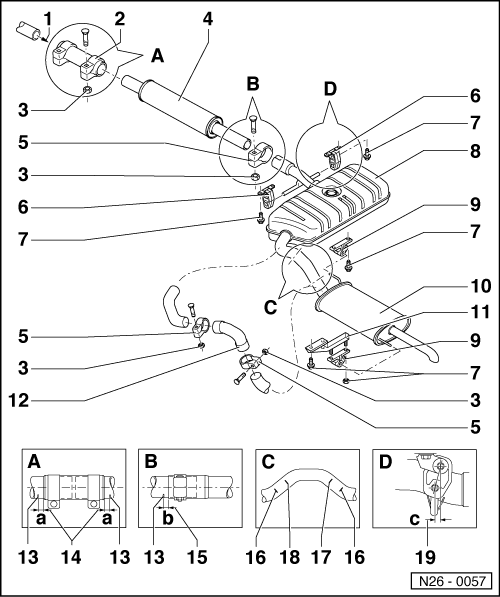

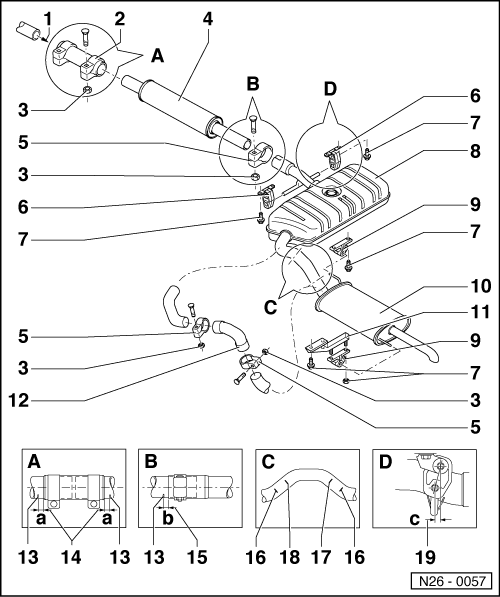

Exhaust manifold, front exhaust pipe and catalyst with attachments

|

|

|

|

=> Repair group 24; Digifant injection and ignition system; Checking Lambda probe and Lambda control

|

|

|

|

|

|

|

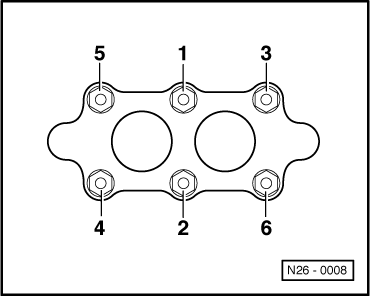

→ Fig. 1 Tightening sequence exhaust pipe to exhaust manifold |

|

|

|

Silencer with mountings Note: Align the exhaust system longitudinally so that the dimensions -14 -, -15 -, and -19 - are maintained. |

|

|

|

|

|

1) As standard central and rear silencer are installed as one component. In repair cases the central and rear silencer are supplied individually and a repair connecting pipe item 12 with two clamps supplied as a joint. Cut through connecting pipe at separating point -17 - or -18 - at right angles with a body saw e.g. V.A.G 1523. |