Passat (B3)

|

|

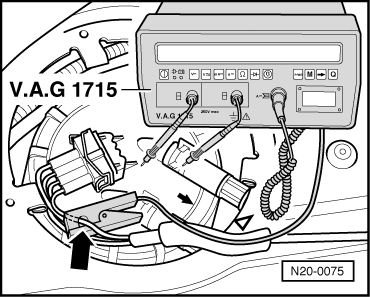

Fuel pump must be heard to run briefly. If the fuel pump does not run:

Notes:

|

|

|

Fuel pump runs:

=> Repair group 01; Self-diagnosis; final control diagnosis Fuel pump does not run:

|

|

|

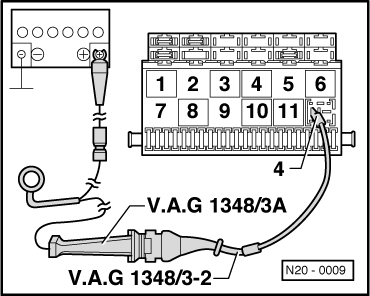

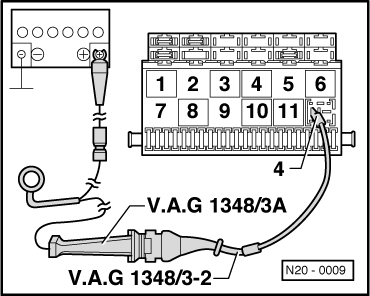

LED does not light up:

LED lights up (voltage supply OK.):

If not open circuit can be found:

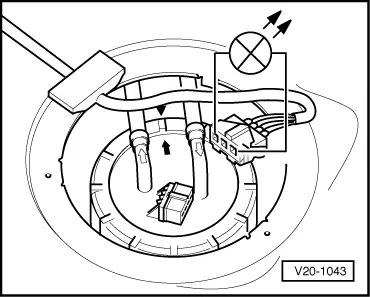

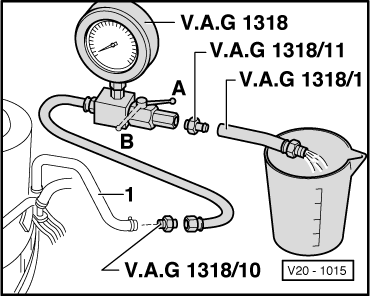

Checking delivery rate

Test sequence

Warning!

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

|

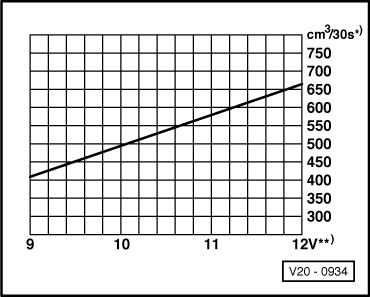

*) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stopped and pump running (approx. 2 volts less than battery voltage). If the minimum delivery rate is not attained:

|

|

|

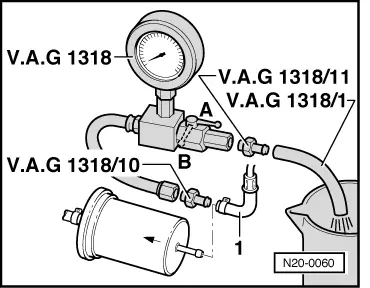

If the minimum delivery rate is now attained:

If the minimum delivery rate is again not attained:

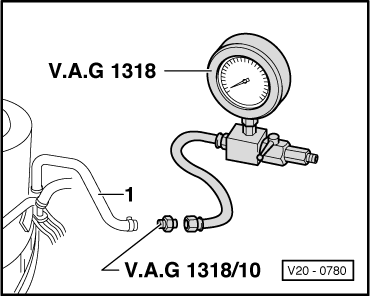

Only when up to now no fault has been detected:

If the delivery rate has been attained but nevertheless you suspect a fuel supply system fault (e.g. intermittent failure of fuel supply system):

|

|

|

|

With this check the fuel supply pipe connections from the fuel delivery unit to the point at which the pressure gauge V.A.G 1318 is connected will be checked for leaks at the same time.

Warning!

Danger of spray when opening the shut-offtap, hold container over the free connection of the pressure gauge.

|