Passat (B3)

|

Removing and installing parts of exhaust system

Removing and installing parts of exhaust system

Exhaust manifold, front exhaust pipe and catalyst with attachments for vehicles ▸ 07.95 Exhaust manifold, front exhaust pipe and catalyst with attachments for vehicles 08.95 ▸ => Page 26-5 Silencer with mountings => Page 26-9 Exhaust gas recirculation system (Vehicles ▸07.95 only) => Page 26-13 Checking secondary air system for vehicles ▸ 07.95 => Page 26-19 Checking secondary air system for vehicles 08.95 ▸ => Page 26-28 Notes:

|

|

|

|

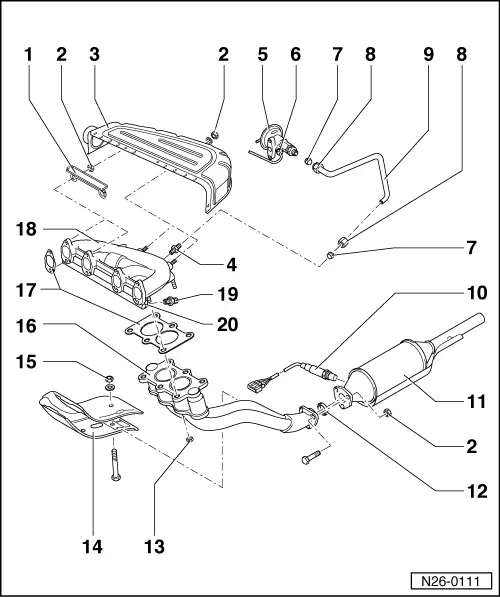

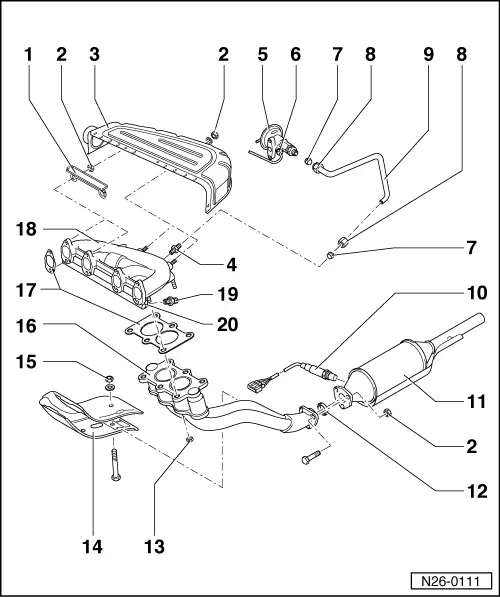

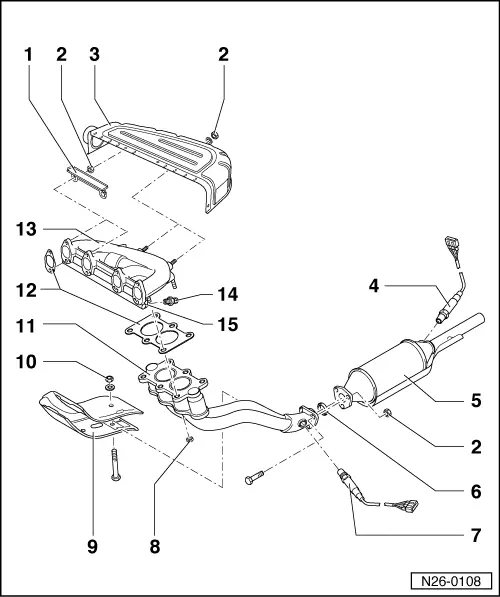

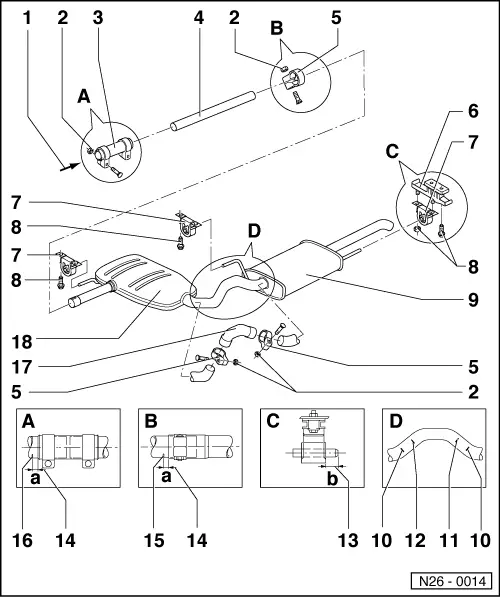

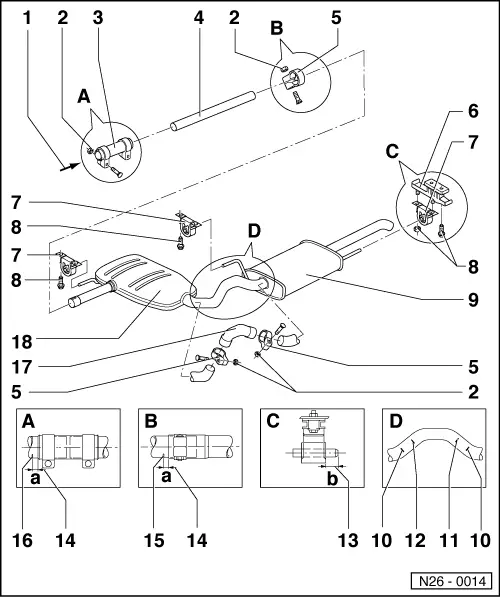

Exhaust manifold, front exhaust pipe and catalyst with attachments Vehicles ▸07.95 |

|

|

=> Repair group 24; servicing injection and ignition system

|

|

|

|

|

|

|

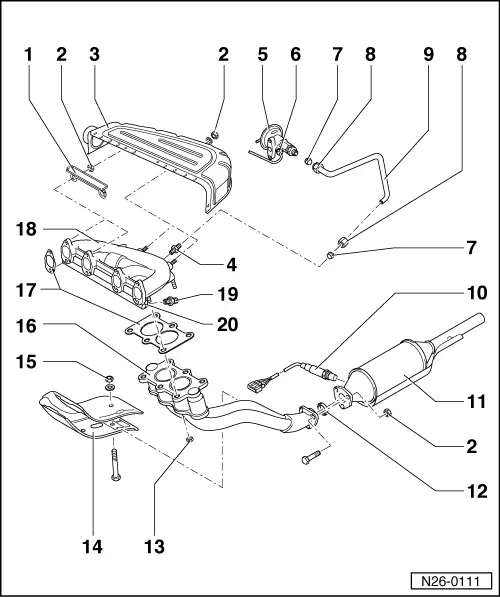

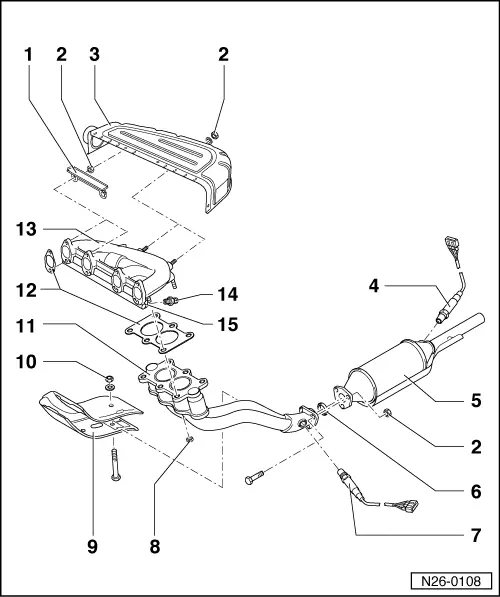

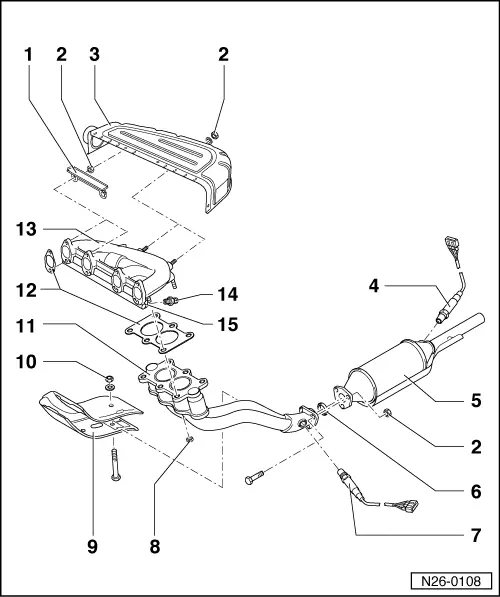

Exhaust manifold, front exhaust pipe and catalyst with attachments Vehicles08.95 ▸ |

|

|

=> Repair group 24; servicing injection and ignition system

|

|

|

|

|

|

|

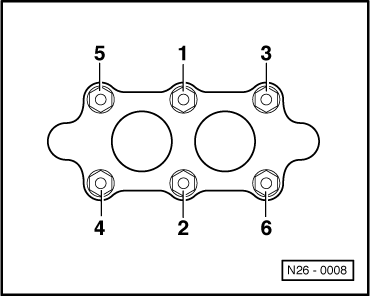

→ Fig. 1 Tightening sequence exhaust pipe to exhaust manifold |

|

|

|

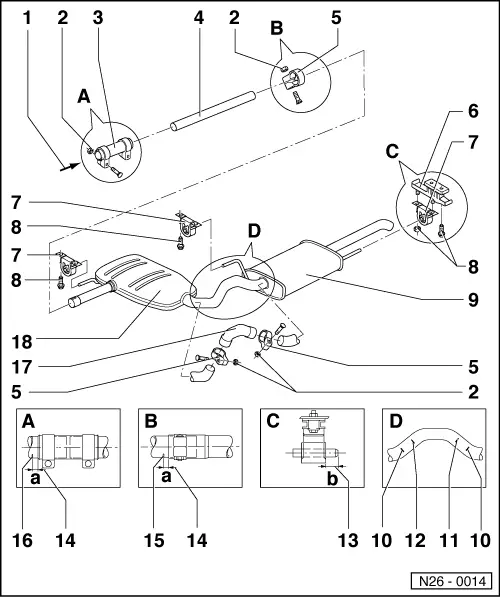

Silencer with mountings Note: Align the exhaust system longitudinally so that the dimensions -a-, -b- and -c- are maintained. |

|

|

|

|

|

|