|

Servicing Diesel direct injection system

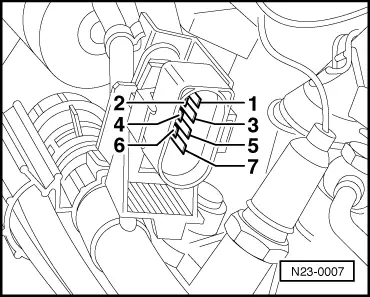

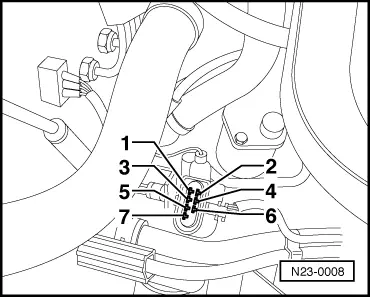

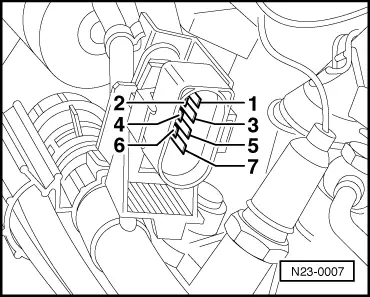

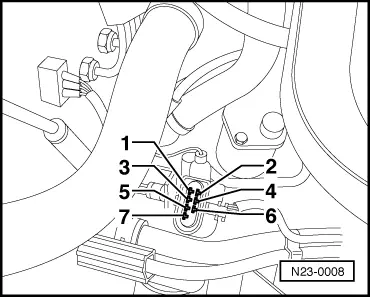

Checking modulating piston movement sender and quantity adjuster

The quantity adjuster is an electro-magnetic swivelling positioner which is controlled by the control unit via a directed duty cycle (on-off ratio). The eccentric shaft on the quantity adjuster moves the modulating piston on the high pressure piston and thereby regulates the quantity of fuel injected.

The modulating piston movement sender informs the control unit of the position of quantity adjuster -N146 and therefore stipulates the amount injected.

Special tools, testers, measuring instruments and auxiliary items required

-

◆ Fault reader V.A.G 1551 or vehicle system tester V.A.G 1552 with cable V.A.G 1551/3

-

◆ Test box V.A.G 1598/18

-

◆ Hand multimeter V.A.G 1526 or multimeter V.A.G 1715

-

◆ Adapter set V.A.G 1594

-

◆ Current flow diagram

Test sequence

-

‒ Connect fault reader V.A.G 1551 and select engine electronics control unit (address word 01); selection is carried out with engine idling.

|