|

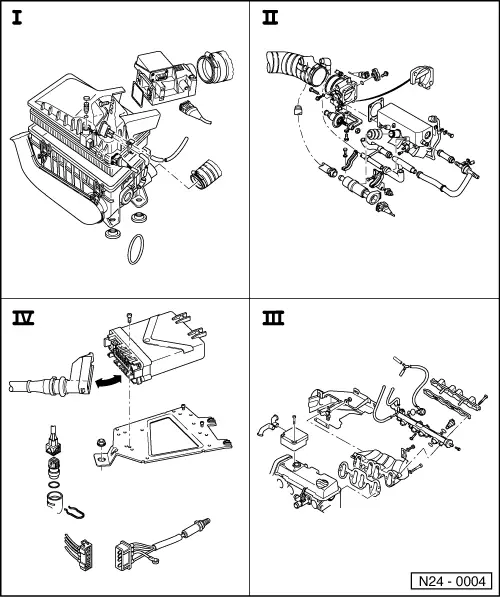

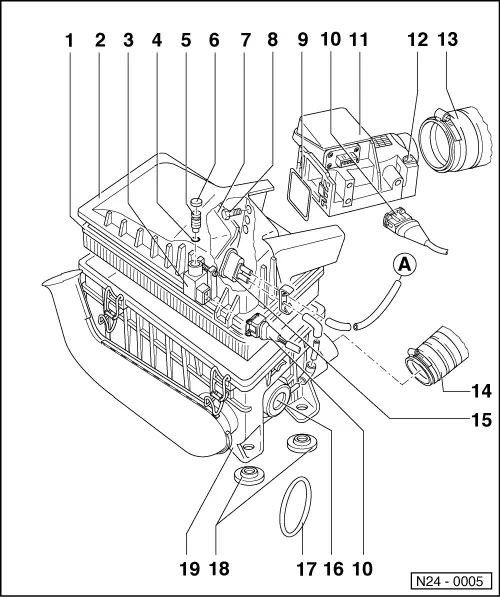

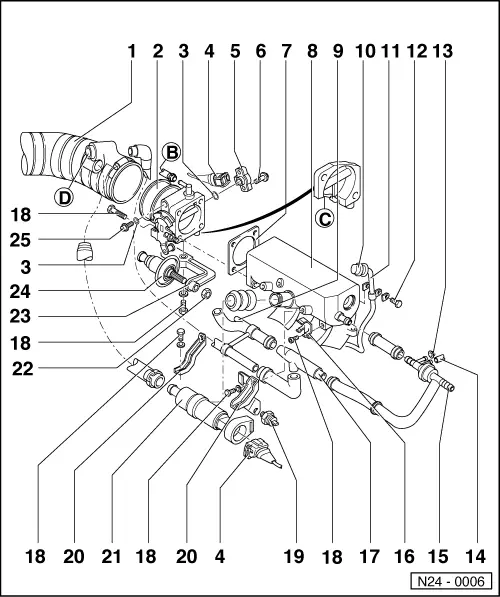

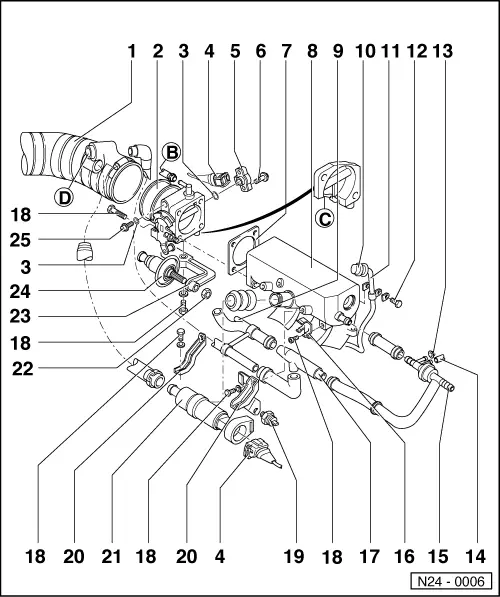

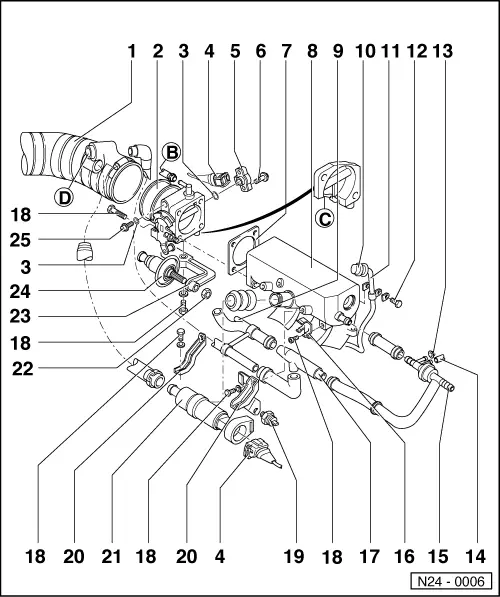

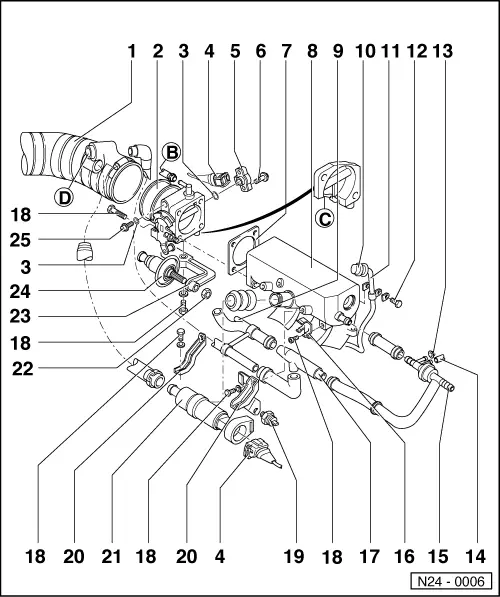

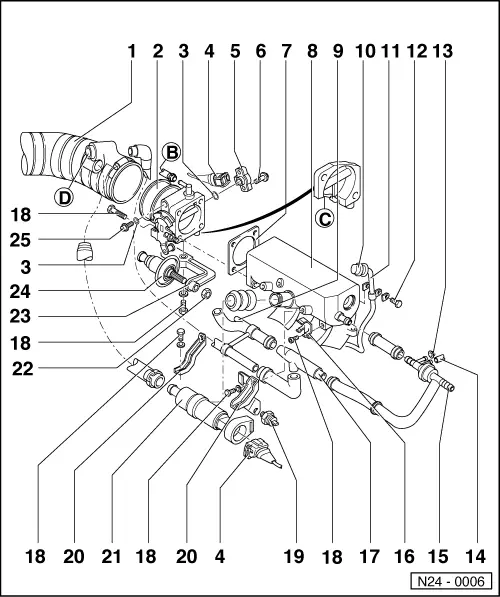

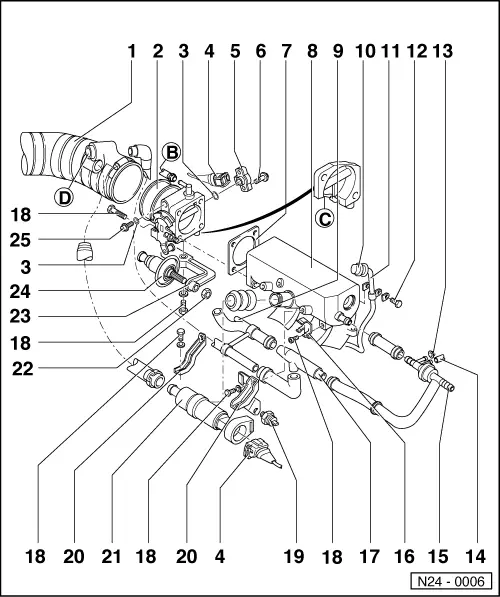

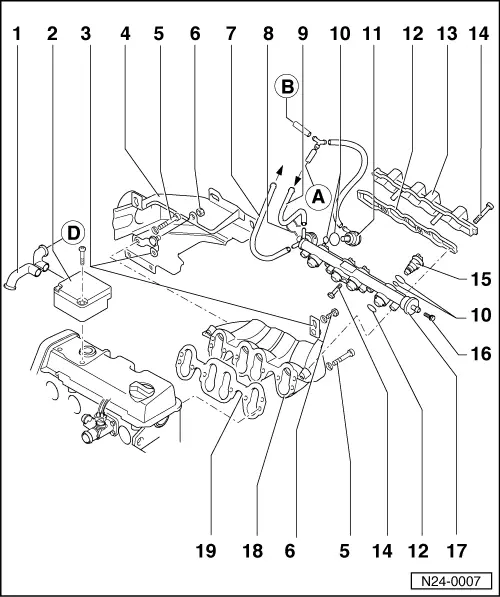

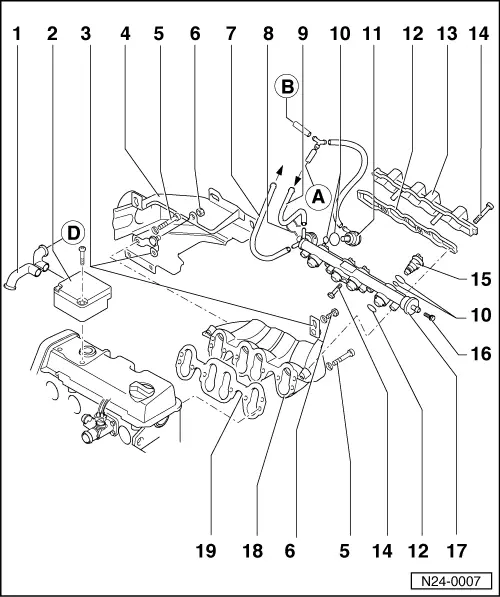

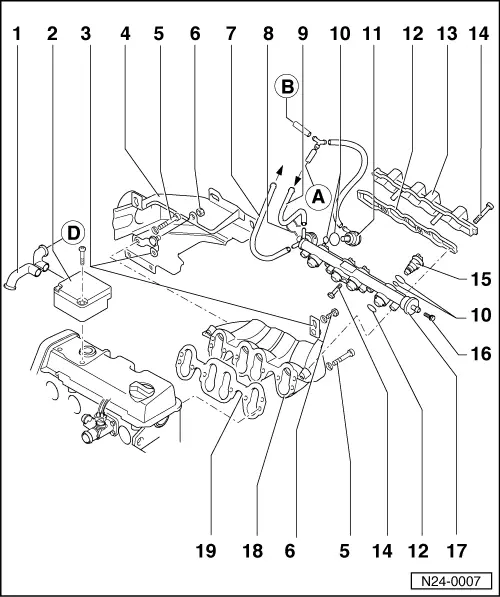

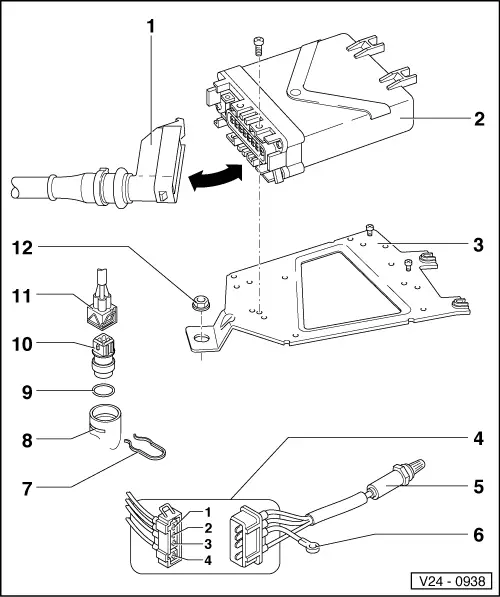

Digifant injection and ignition system

Servicing injection part

Servicing ignition part=>Repair group 28

Notes:

-

◆ Fuel hoses in engine compartment must only be secured with spring type clips. The use of clamp or screw type clips is not permissible.

-

◆ The control unit for the fuel injection and ignition system is equipped with a fault memory. Before carrying out repairs, adjustment work and fault finding the fault memory must be interrogated and the vacuum connections checked (outside air).

-

◆ Components marked with * are checked via the self diagnosis.

, interrogating and erasing fault memory

-

◆ Components marked with ** are checked via the final control control diagnosis => Page 01-12

.

-

◆ For trouble-free operation of the electrical components a voltage of at least 11.5 V is necessary.

-

◆ Do not use sealants containing silicone. Particles of silicone drawn into the engine, will not be burnt in the engine and damage the Lambda probe.

Safety precautions

Rules for cleanliness => Page 24-24

Technical data => Page 24-25

Self diagnosis and electrical check of the injection and ignition system => Repair group 01

Checking intake system for leaks (unmetered air) => Page 24-54

|