Passat (B3)

| Removing and installing subframe, anti-roll bar and suspension link (basic running gear) |

Note

Note| t | If a vehicle has to be moved after the drive shaft has been removed, first install an outer joint instead of the drive shaft and tighten to 50 Nm because otherwise the wheel bearing will be damaged. |

| t | Wheel alignment specifications → Chapter |

| t | It is not permitted to weld or straighten suspension parts which bear loads or locate the wheels. |

| t | Always renew self-locking nuts. |

| t | Always renew corroded nuts and bolts. |

| 1 - | Hexagon bolt, 35 Nm |

| 2 - | Swivel joint |

| q | Checking → Chapter. |

| q | Check rubber boot for damage, renew swivel joint if necessary. |

| q | Mark installation position; if suspension link is renewed, set to centre of elongated hole and check toe setting. |

| q | Elongated holes are not used to set camber! Non-observance may damage drive shafts. |

| 3 - | Plate with nuts |

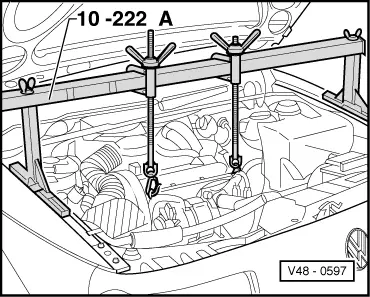

| 4 - | Air guide |

| q | Secured by clip to suspension link. |

| 5 - | Rear suspension link bush |

| 6 - | Rear suspension link bush |

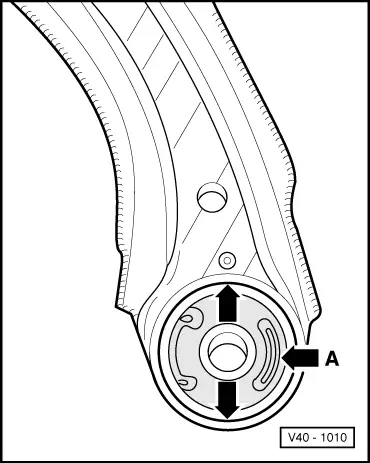

| q | Installation position → Fig.. |

| q | Pressing out and in → Fig.. |

| 7 - | Hexagon bolt M12 x 1.5 x 82 |

| q | 50 Nm and turn 90° further. |

| 8 - | Hexagon bolt M12 x 1.5 x 65 |

| q | 70 Nm and turn 90° further. |

| 9 - | Hexagon bolt M12 x 1.5 x 78 |

| q | 70 Nm and turn 90° further. |

| 10 - | Front suspension link bush |

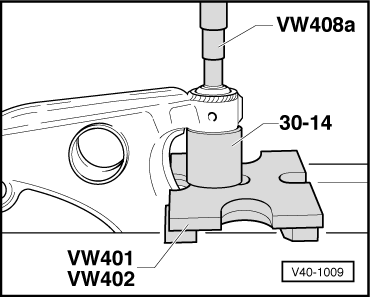

| q | Pressing out → Fig.. |

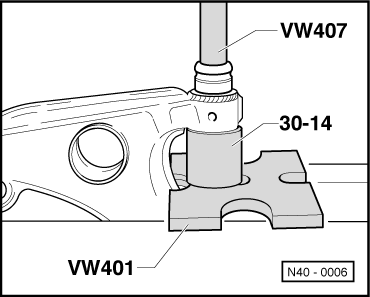

| q | Pressing in → Fig.. |

| 11 - | Coupling rod |

| q | With rubber bush. |

| 12 - | Mounting for coupling rod |

| q | Conical side to suspension link. |

| 13 - | Washer |

| q | Collar faces away from mounting. |

| 14 - | Self-locking hexagon nut, 20 Nm |

| 15 - | Subframe |

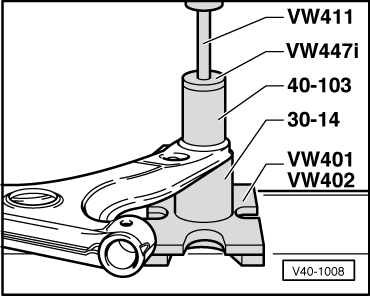

| q | Removing and installing when assemblies are installed: support assemblies → Fig.. |

| q | Take subframe with suspension links (but without steering box) out downwards using engine and gearbox jack -V.A.G 1383 A-. After installing, check front wheel alignment and position of steering wheel. |

| q | Aligning engine/gearbox assembly → Engine; Rep. Gr.10. |

| 16 - | Hexagon bolt, 65 Nm |

| 17 - | Anti-roll bar bush |

| 18 - | Anti-roll bar |

| 19 - | Anti-roll bar clamp |

| 20 - | Hexagon bolt, 25 Nm |

| q | To secure anti-roll bar. |

| 21 - | Vibration damper |

| q | Note installation position; larger part must project over subframe. |

| 22 - | Self-locking hexagon nut, 25 Nm |

| 23 - | Cap nut |

| q | Reworking in longitudinal member → Chapter. |

|

|

Note

Note

|

|

Note

Note

|

|

|

|