Polo Mk3

|

Servicing gear change mechanism

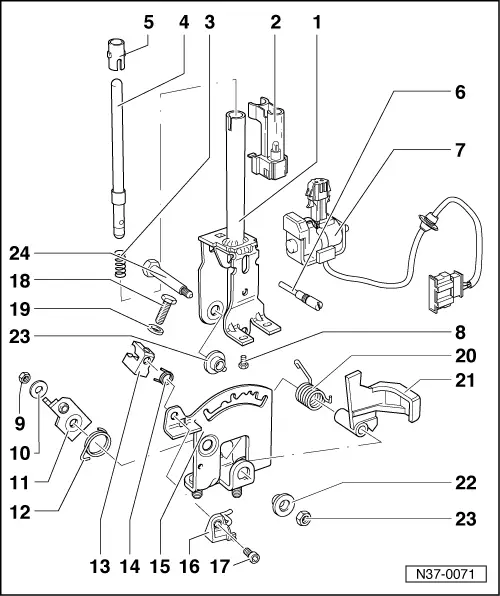

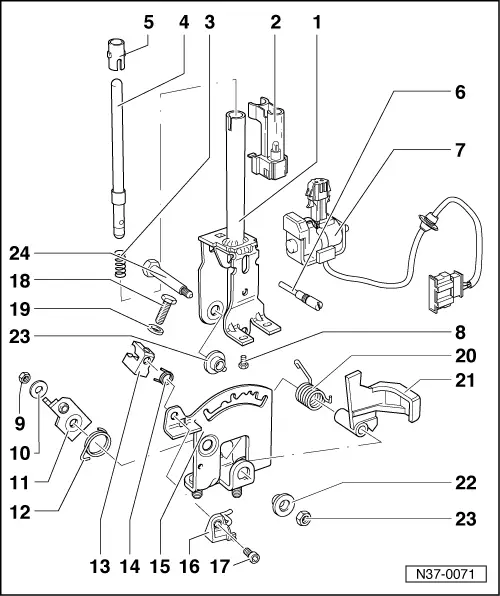

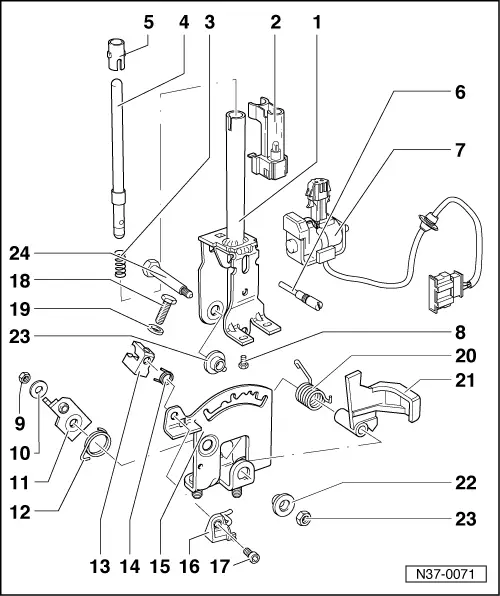

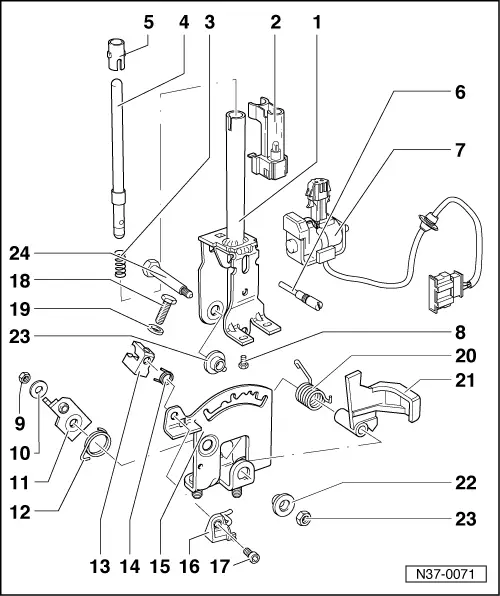

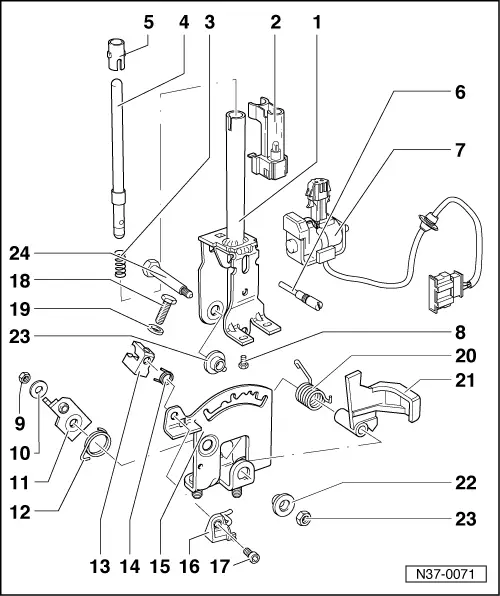

Dismantling and assembling selector lever on vehicles with ignition key removal lock up to 06.99

|

|

|

|

Selector lever must be removed to renew individual parts . Lubricate all mountings and sliding surfaces with Polyurea grease Part No. G 052 142 A2. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

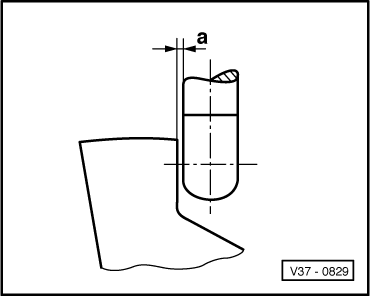

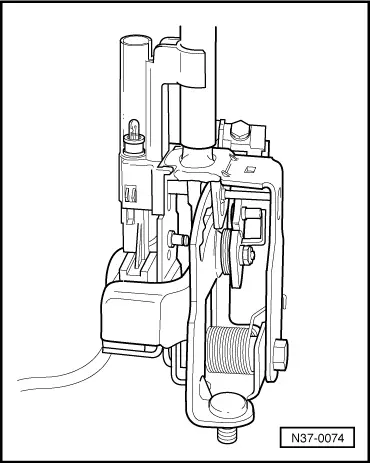

→ Fig.1 Assembling selector lever before installing Adjust solenoid for selector lever lock -N110- and carry out functional check => Fig. 3 before installing selector lever in selector lever housing.

|

|

|

|

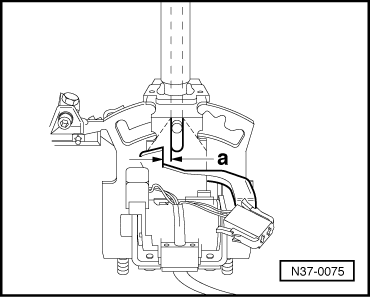

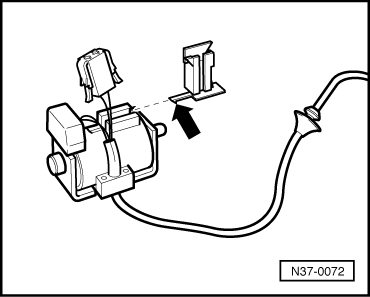

→ Fig.2 Adjusting selector lever lock solenoid -N110-

|

|

|

|

→ Fig.4 Securing indicator lighting connector

|