| –

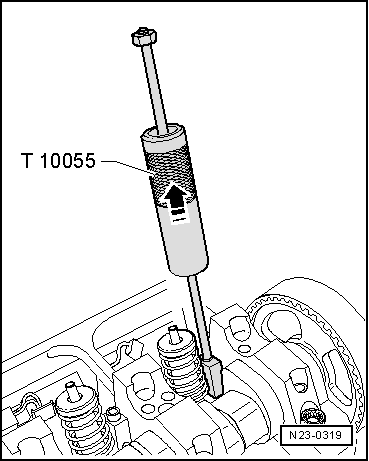

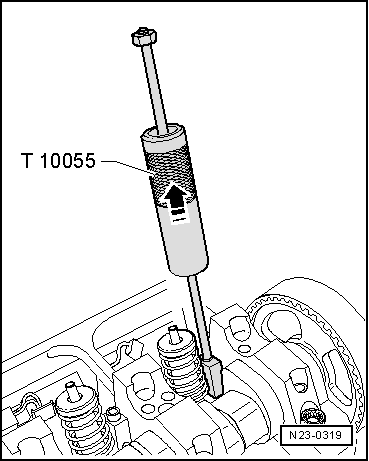

| Insert puller -T10055- in the slot on the side of the unit injector in place of the clamping block. |

| –

| Pull unit injector out of cylinder head seat with gentle taps. |

Note | t

| If a new unit injector is installed, the appropriate adjustment screw in the rocker arm must also be renewed. |

| t

| Each time work is performed which requires the unit injector to be adjusted, the adjustment screw in the rocker arm and also the unit injector ball pin must be cleaned and checked for signs of wear. If wear is evident the ball pin and the adjustment screw must be renewed. |

| t

| On older version of unit injector drive, lubricate contact surface between ball pin and adjustment screw with grease -G 000 100-. |

| t

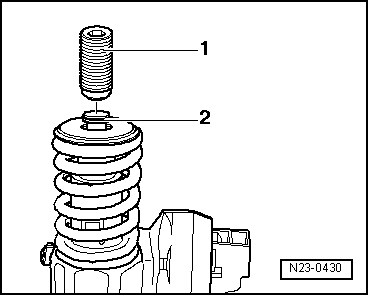

| New unit injectors are supplied with O-rings and heat shield seal. |

| –

| Heat shield seal and O-rings must be renewed if old unit injector is reused → Chapter. |

| –

| Check that the three O-rings and the heat shield seal along with securing clip are seated correctly before installing unit injector. |

Note | The seals must not be twisted. |

| –

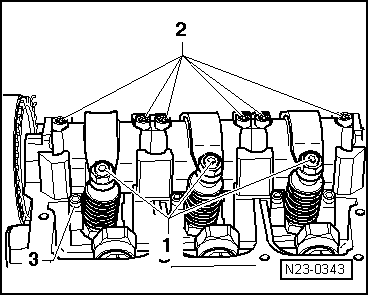

| Oil the seals and fit the unit injector into the cylinder head with great care. |

| –

| Push the unit injector evenly into the cylinder head onto its limit stop. |

| –

| Insert the clamping block in the slot on the side of the unit injector. |

Note | If the unit injector is not at right angles to the tensioning block the securing bolt may loosen and this can damage the unit injector or the cylinder head. |

| –

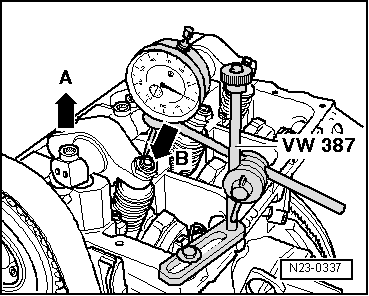

| Therefore align the unit injector as follows. |

| –

| Screw the new securing bolt into the tensioning block only so far that the unit injector can still be turned easily. |

| –

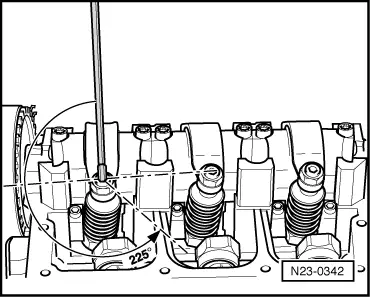

| Now align unit injector at right angles to camshaft mounting brackets. |

| –

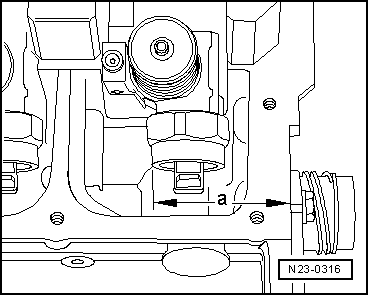

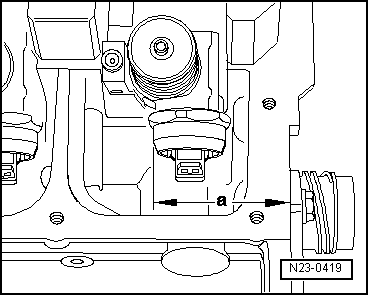

| Check dimension “a” from outer edge of cylinder head to rounded edge of unit injector with a vernier gauge (measuring range at least 400 mm). |

Note | Gradual introduction of unit injector with new solenoid valve nut. A mixed installation is permissible providing measurement “a” is adhered to. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note Note

Note