Polo Mk3

|

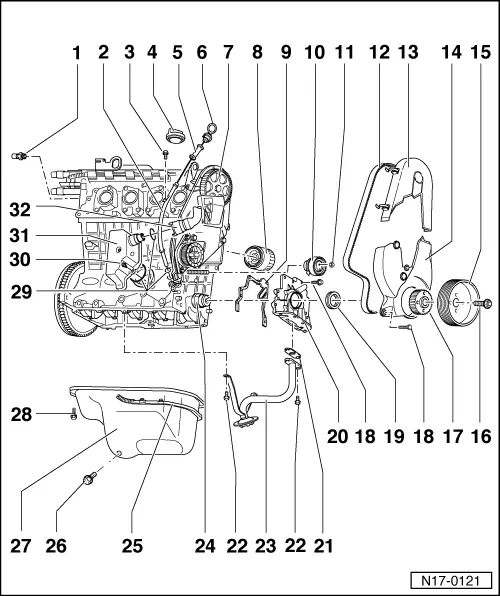

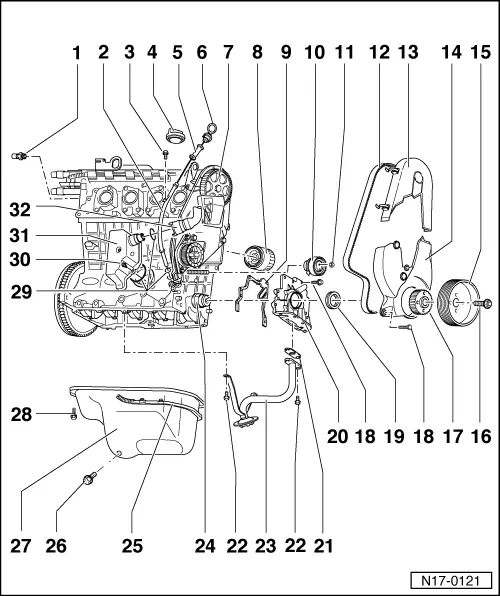

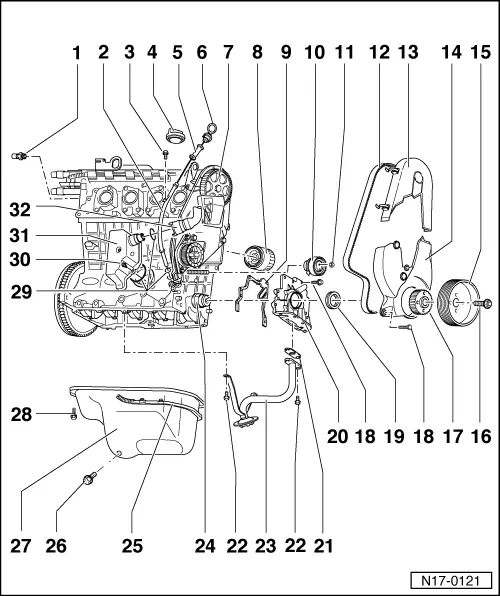

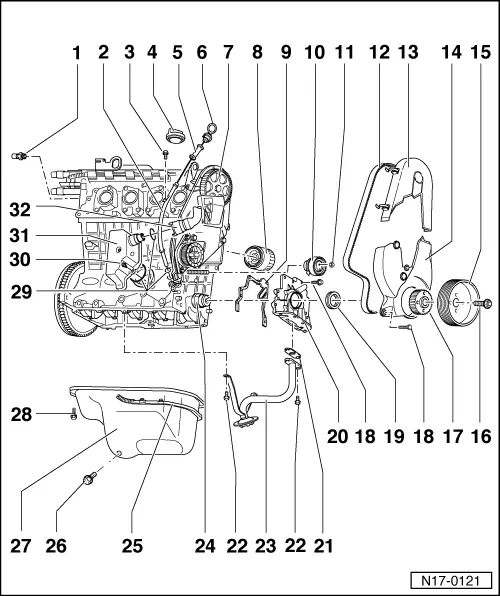

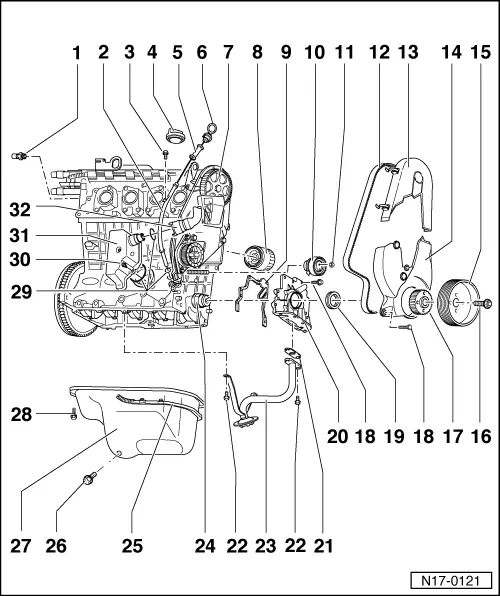

Removing and installing parts of the lubrication system

Removing and installing parts of the lubrication system

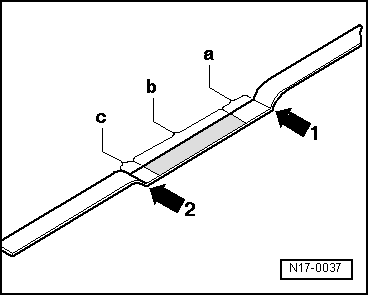

Note: The oil level must not be above the max. mark - danger of damaging catalyst! Marks , Fig. 1 . Checking oil pressure => Page 17-16 Oil system capacity1): with oil filter 3.2 ltr. 1) Up-to-date figures: => Exhaust emissions test binder Engine oil specifications: Use engine oil to VW standard 500 00, 501 01 or 502 00. Only in exceptional cases: Multi-grade oils corresponding to API-SF or SG. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|