Polo Mk3

|

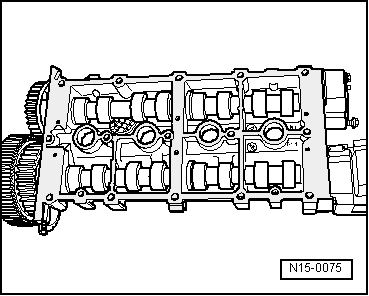

Removing and installing cylinder head

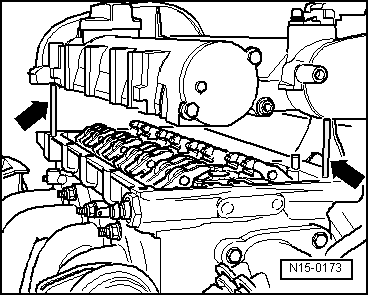

Removing and installing camshaft housing

|

|

|

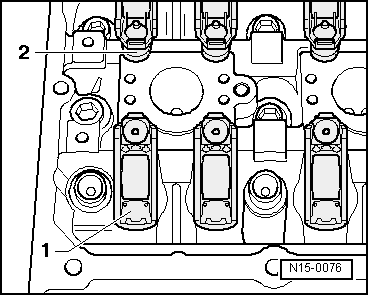

Installing Prerequisites

Note: If a piston is at TDC the valves could strike the piston when turning the camshafts.

|

|

|

Note: The sealant must not be applied too thick otherwise excess sealant can enter the oil channels and cause damage to the engine. |

|

|

|

|

|

Ensure that camshaft housing is not canted. Note:

The rest of the assembly is basically a reverse of the dismantling sequence. |