Polo Mk3

|

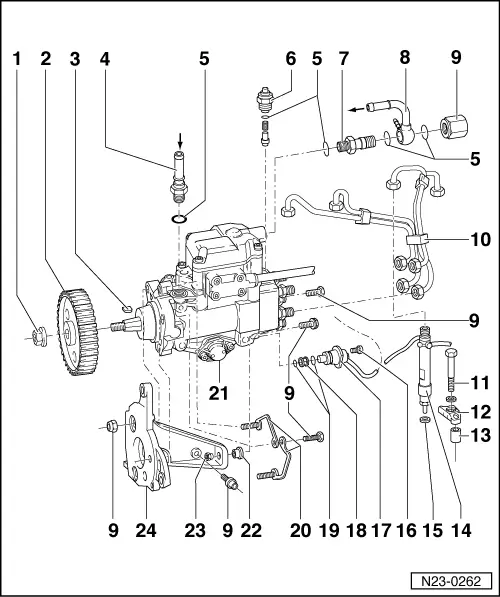

| 1 - | 55 Nm |

| 2 - | Injection pump belt pulley |

| q | One-piece. |

| q | Removing and installing → Chapter, Removing and installing injection pump. |

| 3 - | Woodruff key |

| q | Check for secure seating. |

| 4 - | Union, 25 Nm |

| q | For supply line. |

| q | From fuel filter: → Engine mechanical system; Rep. Gr.20. |

| 5 - | Seal |

| q | Renew |

| 6 - | Fuel shut-off valve -N109-, 40 Nm |

| 7 - | Union |

| q | For return pipe |

| 8 - | Return line |

| q | To regulating valve/fuel filter: → Engine mechanical system; Rep. Gr.20. |

| 9 - | 25 Nm |

| 10 - | Injector pipes |

| q | Tighten to 25 Nm |

| q | Remove with ring spanner -3035- |

| q | Always remove pipework complete |

| q | Do not alter shape |

| 11 - | 20 Nm |

| 12 - | Retainer |

| 13 - | Mounting bracket |

| 14 - | Injector |

| q | Removing and installing → Chapter |

| q | Checking → Chapter. |

| q | For cylinder 3 with needle lift sender -G80-. |

| q | Checking needle lift sender -G80- → Chapter |

| 15 - | Heat shield seal |

| q | Renew |

| 16 - | 10 Nm |

| 17 - | Commencement of injection valve -N108- |

| q | Checking → Chapter, Checking injection timing device control range. |

| 18 - | Strainer |

| q | Clean strainer if soiled. |

| 19 - | O-ring |

| q | Renew |

| 20 - | Bracket |

| 21 - | Injection timing device cover |

| q | Renew O-ring if leaking. |

| 22 - | Sleeve |

| q | Tapered. |

| 23 - | 25 Nm |

| q | Nut with taper. |

| 24 - | Bracket |

| q | Removing and installing: → Engine mechanical system; Rep. Gr.13. |