Polo Mk3

|

Servicing drive shaft

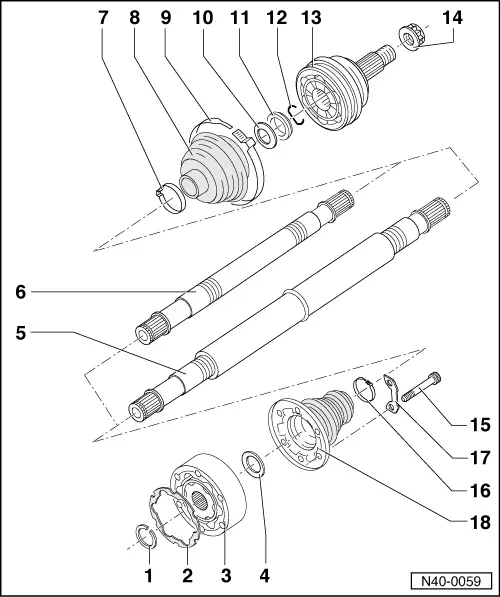

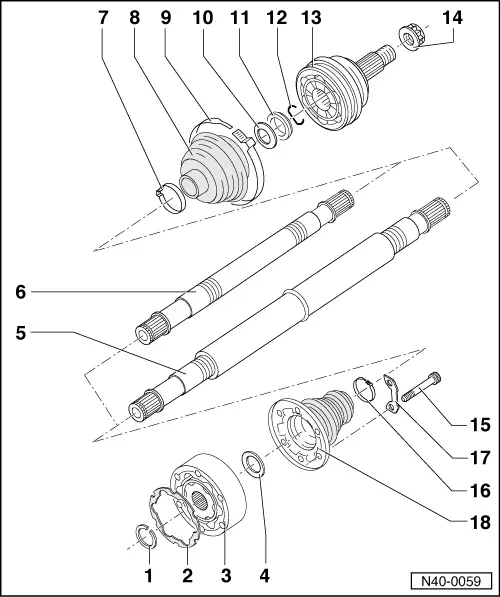

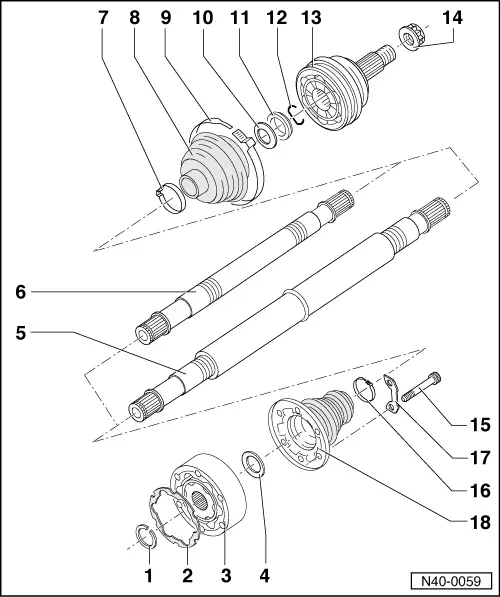

Assembly overview drive shaft with constant velocity joint

|

|

|

|

|

|

|

|

|

|

|

|

|

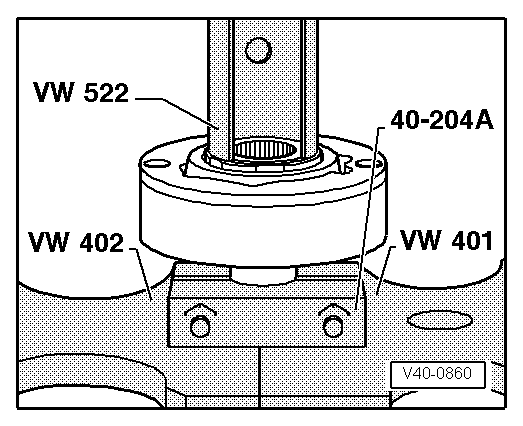

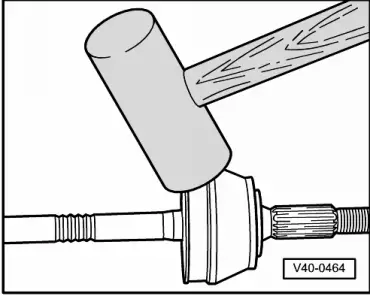

→ Fig.1 Removing outer constant velocity joint

|

|

|

|

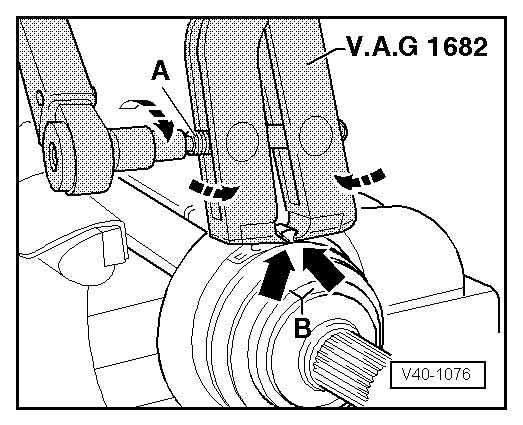

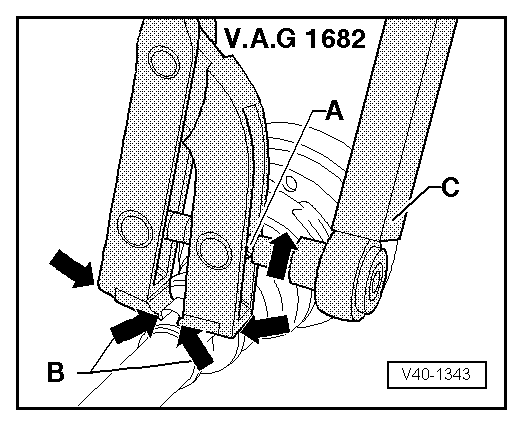

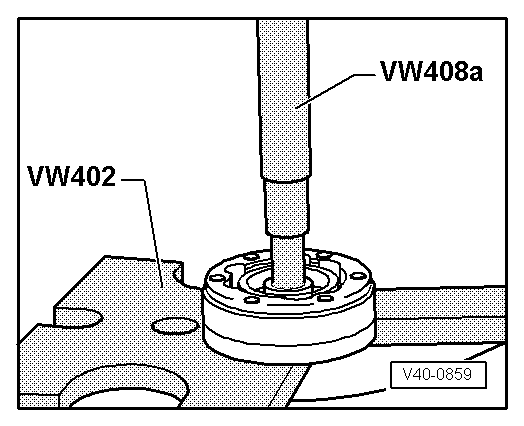

→ Fig.2 Pressing off inner constant velocity joint Notes:

|