Polo Mk3

|

Servicing wheel bearings

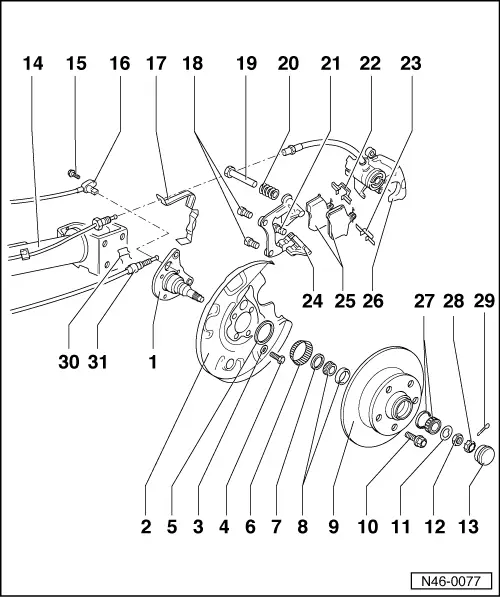

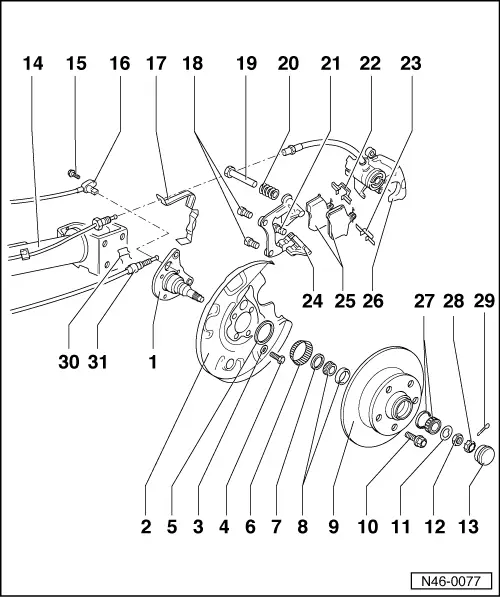

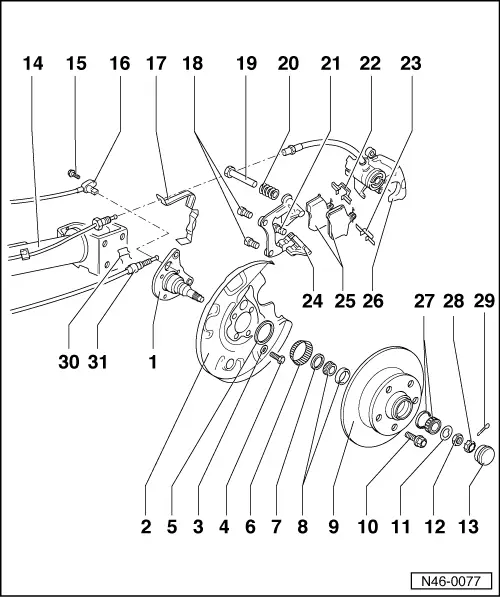

Assembly overview wheel bearings, disc brakes>09.99

|

|

|

|

|

|

=> Maintenance manual

=> Brake system; Repair group 46; Servicing rear brakes (disc brakes) |

|

|

=> Brake system; Repair group 46; Servicing rear brakes (disc brakes)

=> Brake system; Repair group 46; Servicing rear brakes (disc brakes)

=> Brake system; Repair group 46; Servicing rear brakes (disc brakes) |

|

|

|

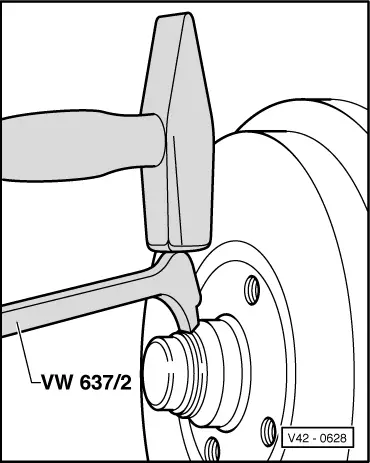

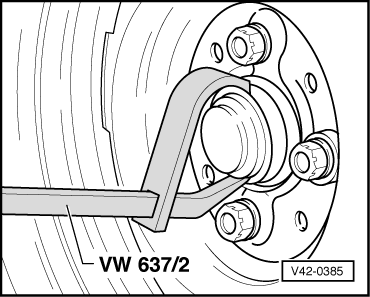

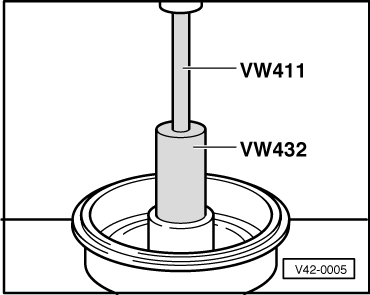

→ Fig.1 Pressing off grease cap Loosen grease cap from seat by tapping lightly on the claw. |

|

|

|

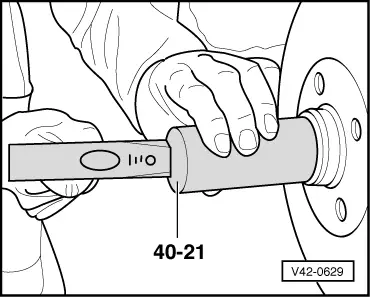

→ Fig.2 Pressing off grease cap |

|

|

|

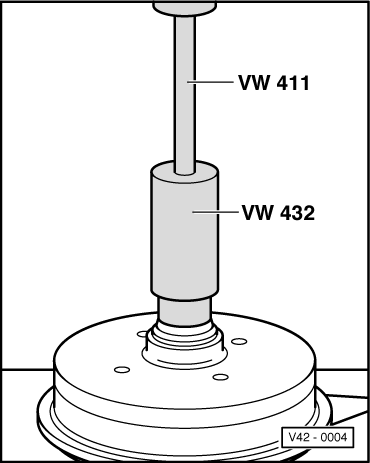

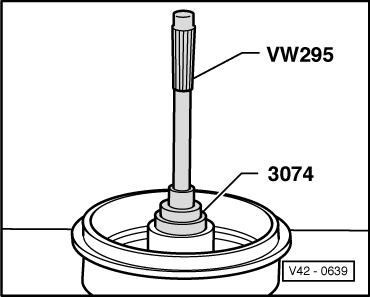

→ Fig.3 Driving in grease cap Notes:

|

|

|

|

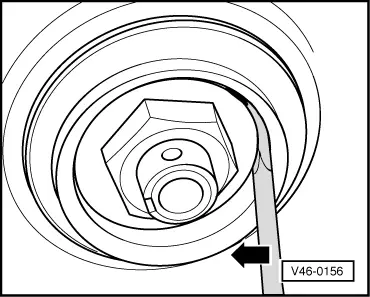

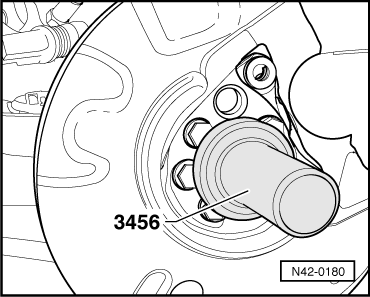

→ Fig.4 Adjusting wheel bearing play Note: Using a screwdriver it must be possible to move the thrust washer by finger pressure (without leverage).

|

|

|

|

→ Fig.5 Pressing in outer wheel bearing outer race |

|

|

|

→ Fig.6 Pressing in inner wheel bearing outer race |

|

|

|

→ Fig.7 Driving in oil seal |

|

|

|

→ Fig.8 Driving in cover ring |