Polo Mk4

| Gearbox housing and clutch housing - service |

| Special tools and workshop equipment required |

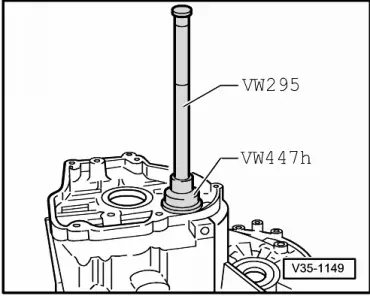

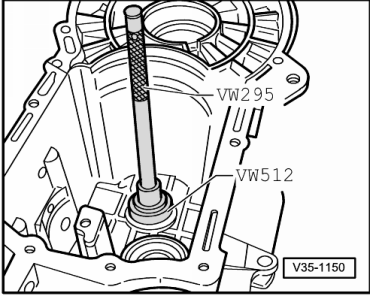

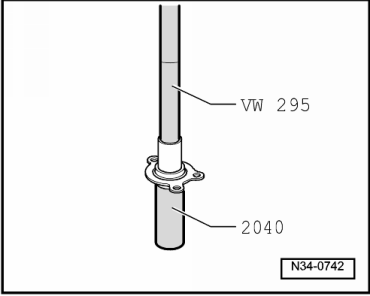

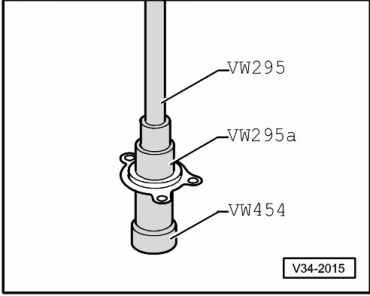

| t | Pin -VW 295- |

| t | Complement -VW 295A- |

| t | Pressure disc -VW 447 H- |

| t | Pressure disc -VW 512- |

| t | Tube -2040- |

| t | Pressure tube -VW 454- |

| t | Pin -VW 222 A- |

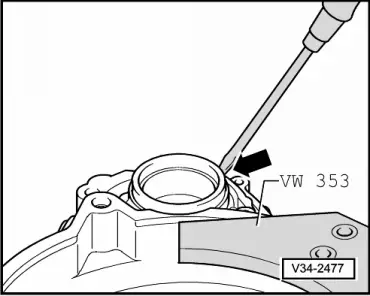

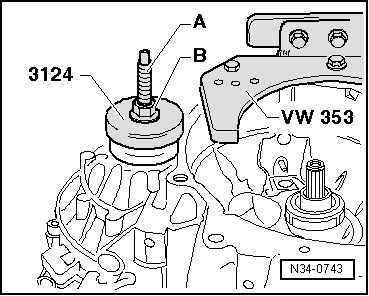

| t | Bracket -VW 353- |

| t | Placer -3066- |

| t | Placer -3124- |

| t | 5 - 50 Nm Torquemeter -VAG 1331- |

| t | Inner puller -Kukko 21/1- |

| t | Counter-support -KUKKO 22/1- |

| 1 - | Gearbox housing |

| q | If replaced: adjust input shaft and differential → Chapter. |

| 2 - | Oil filling plug, 30 Nm |

| q | Without magnet. |

| 3 - | Needle roller bearing |

| q | For output shaft. |

| q | Remove → Fig. |

| q | Install → Fig. |

| 4 - | Adjustment shim |

| q | For output shaft. |

| q | Adjustment overview → Chapter. |

| 5 - | Outer race/taper roller bearing |

| q | For output shaft. |

| q | Remove and install → Fig. |

| q | In case there is replacement: adjust output shaft → Chapter |

| 6 - | Outer race/taper roller bearing |

| q | For input shaft. |

| q | Remove and install → Fig. |

| q | In case there is replacement: adjust input shaft → Chapter. |

| 7 - | Adjustment shim |

| q | For input shaft. |

| q | Adjustment overview → Chapter. |

| 8 - | Outer race/taper roller bearing |

| q | For input shaft. |

| q | Remove and install → Fig. |

| q | In case there is replacement: adjust input shaft → Chapter |

| 9 - | Needle roller bearing |

| q | Remove and install → Fig. |

| 10 - | Dowel sleeve |

| q | (2 units) |

| 11 - | Clutch housing |

| q | If replace: adjustment overview → Chapter. |

| 12 - | Ball stud, 25 Nm |

| 13 - | Bearing guide |

| q | With input shaft seal and a vulcanised O ring. |

| q | Remove oil seal → Fig. |

| q | Install oil seal → Fig. |

| q | Remove bearing guide to change the oil seal. |

| q | If damaged replace bearing guide and O ring together. |

| 14 - | Socket head bolt, 20 Nm |

| q | Self-locking. |

| q | Always renew. |

| 15 - | Oil seal |

| q | Replace → Chapter. |

| 16 - | Bushing |

| q | For oil seal ( → Item). |

| q | Remove → Fig. |

| q | Install → Fig. |

| 17 - | Speedometer drive, 10 Nm |

| 18 - | Oil drain plug, 30 Nm |

| q | Without magnet. |

| 19 - | Outer race/taper roller bearing |

| q | For differential. |

| q | Remove and install → Chapter. |

| q | If replacing: adjust differential → Chapter. |

| 20 - | Magnet |

| q | Held in place by housing joint surface. |

| 21 - | Outer race/taper roller bearing |

| q | For differential. |

| q | Remove and install → Chapter. |

| q | If replacing: adjust differential → Chapter. |

| 22 - | Adjustment shim |

| q | For differential. |

| q | Adjustment overview → Chapter. |

| 23 - | Oil seal |

| q | Replace → Chapter. |

|

|

|

|

|

|

|

|

|

|

|

|

| A - | Install spindle of the Placer -3066- into threaded piece of the differential | |

| B - | Nut M12 with ring | |

Note

Note

|